Magnetic stirring device for preparing battery electrolyte

A magnetic stirring device and magnetic stirrer technology are applied in the directions of mixer accessories, dissolving, transportation and packaging, etc., which can solve the problems of large influence factors of personnel, difficult to control process temperature and product quality, time-consuming and labor-intensive, etc., saving manpower and material resources, The effect of shortening the preparation time and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

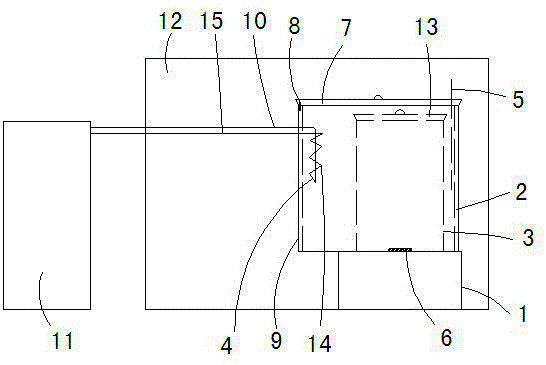

[0011] A magnetic stirring device for preparing battery electrolyte. A barrel body 2 made of stainless steel is arranged on a speed-regulating magnetic stirrer 1. A container 3 made of stainless steel and a cooling rod 4 are arranged inside the barrel body 2. The barrel body 2 and the container 3 is filled with a non-toxic, low freezing point, high boiling point, high safety cold medium - propylene carbonate, the opening of the container 3 is provided with a container cover 13 made of polytetrafluoroethylene, and a magnetic stirring rotor 6 is installed inside, The bung 7 at the opening of the staving 2 is provided with a bung 7 made of polytetrafluoroethylene, the bung 7 is connected with the staving 2 by a vertical shaft 8 arranged on the staving 2, and the bung 7 can take the vertical shaft 8 as a The shaft rotates horizontally relative to the barrel body 2, the barrel cover 7 is provided with a thermometer 5 inserted into the propylene carbonate at the temperature measuring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com