Making method of piezoelectric composite materials

A technology of piezoelectric composite materials and piezoelectric materials, which is applied in the field of two-dimensional surface ultrasonic transducer preparation, can solve problems such as dislocation of microcrystal elements, deformation of piezoelectric composite materials, and influence on the consistency of surface array probes, so as to prevent dislocation , Consistency and reliability, the effect of ensuring correct ordering and regularity of shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

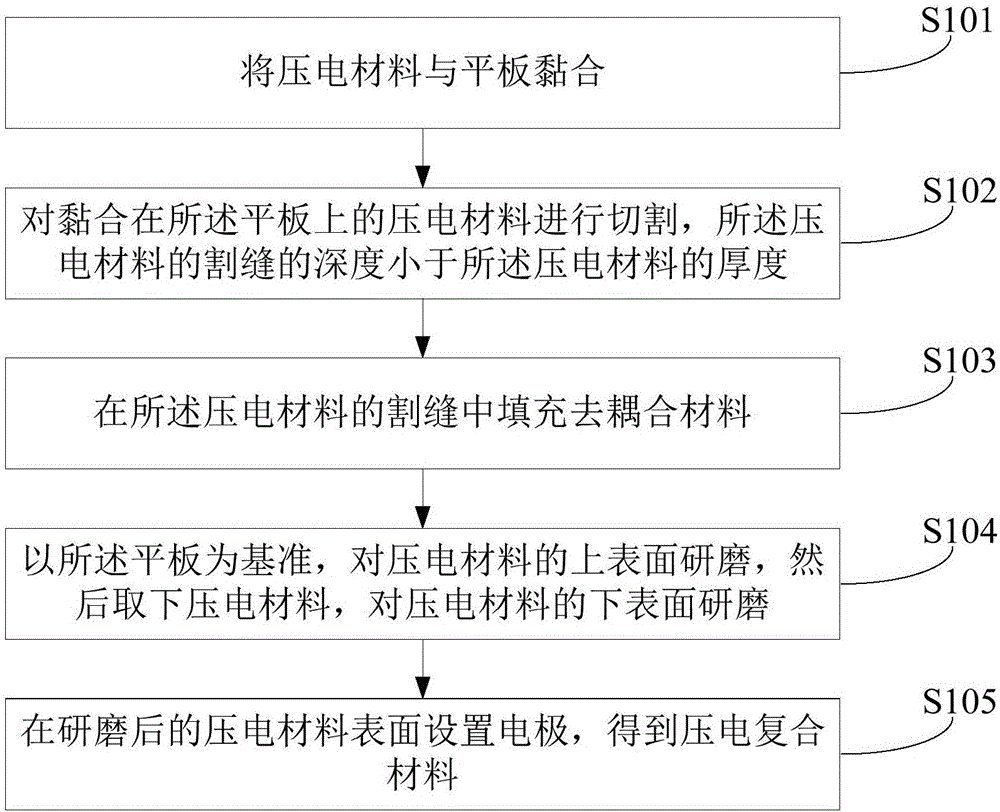

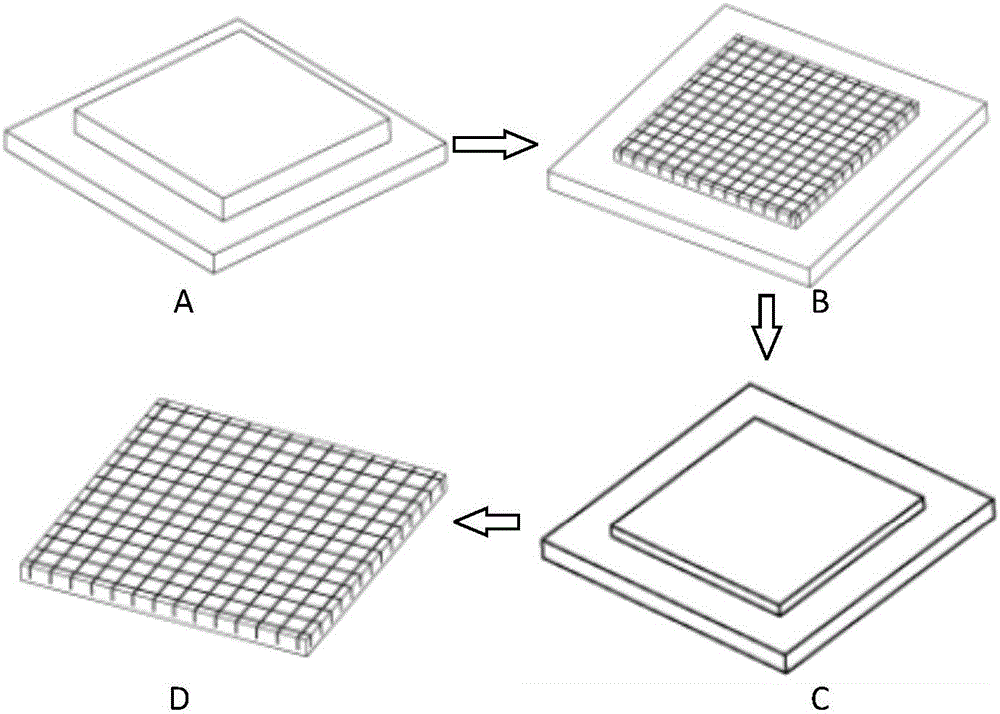

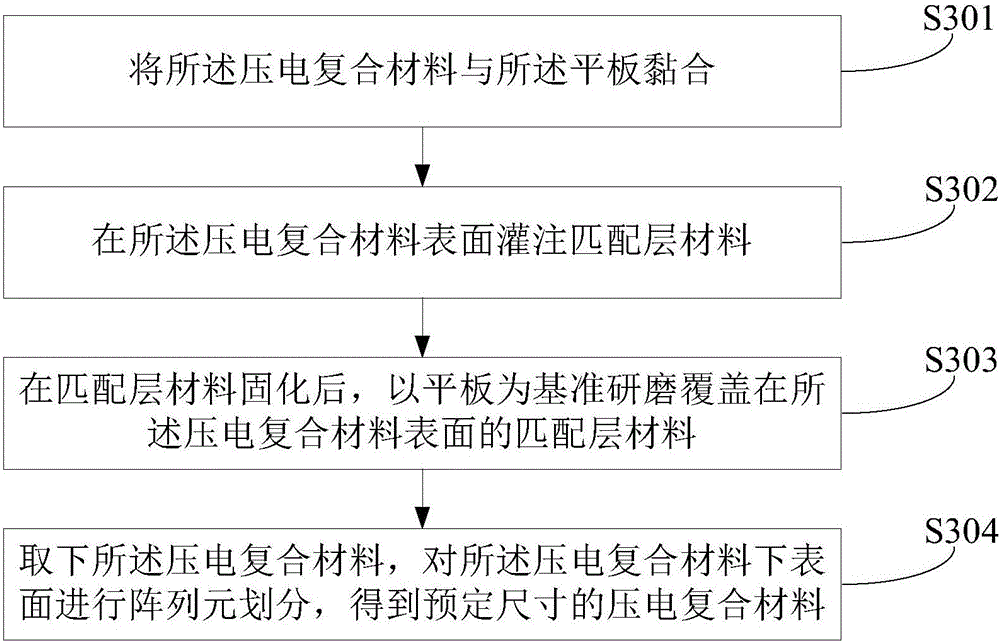

[0036] The purpose of the embodiments of the present invention is to provide a method for manufacturing a piezoelectric composite material to solve the problem of bending and deformation of the piezoelectric ceramic material during the process of manufacturing the piezoelectric composite material and curing the decoupling material in the prior art , so that dislocations are formed between microcrystalline elements; or, clamps are used to suppress during the curing molding process to prevent changes during the curing process, but in the subsequent grinding process of the excess decoupling material, d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com