A glass surface cleaning mechanism

A glass surface and cylinder body technology, applied in the direction of removing smoke and dust, cleaning flexible objects, cleaning methods and utensils, etc., can solve the problems of glass cracking, working environment impact, reducing glass production efficiency, etc., to avoid glass cracking and save energy. energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

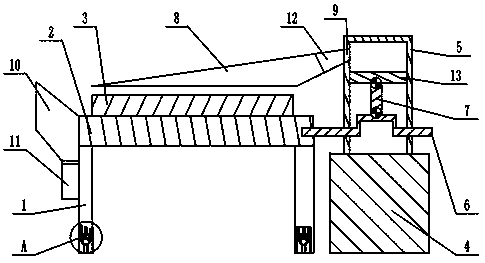

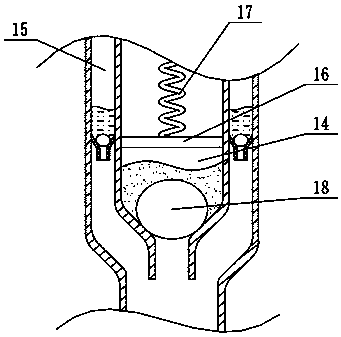

[0021] The reference signs in the drawings of the description include: bracket 1, conveying roller 2, glass 3, frame 4, cylinder block 5, crankshaft 6, connecting rod 7, uniform cover 8, air outlet 9, funnel groove 10, cloth bag 11 , Gooseneck 12, piston 13, first dropper 14, second dropper 15, partition 16, spring 17, ball 18.

[0022] The embodiment is basically as attached figure 1 Shown:

[0023] A glass surface cleaning mechanism, which consists of a conveying roller 2, a bracket 1, a shock-absorbing column, a frame 4, a cylinder body 5, a crankshaft 6 and a connecting rod 7, the conveying roller is installed on the support 1, and the glass is placed on the conveying roller for cleaning. send. A shock-absorbing column is arranged in the bracket 1, a first dropper 14 is arranged in the middle of the shock-absorbing column, a second dropper 15 is arranged on the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com