A kind of design and manufacture method of involute spline broach teeth

A technology of involute spline and manufacturing method, which is applied to broaches, broaching machines, manufacturing tools, etc., can solve the problems of not very high machining accuracy, small broach single tooth lift, and low broaching efficiency. , to achieve the effect of improving cutting efficiency, reducing production and manufacturing costs, and reducing the difficulty of broaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below through the accompanying drawings and specific embodiments, the purpose of which is to enable those skilled in the art to better understand the content of the present invention, rather than to limit the content of the present invention.

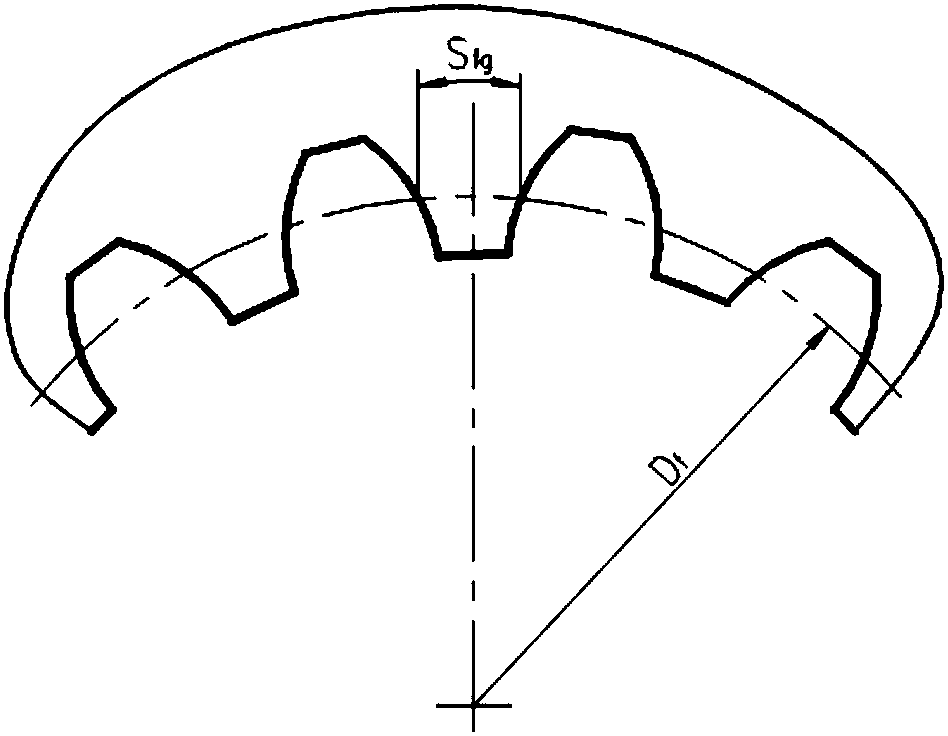

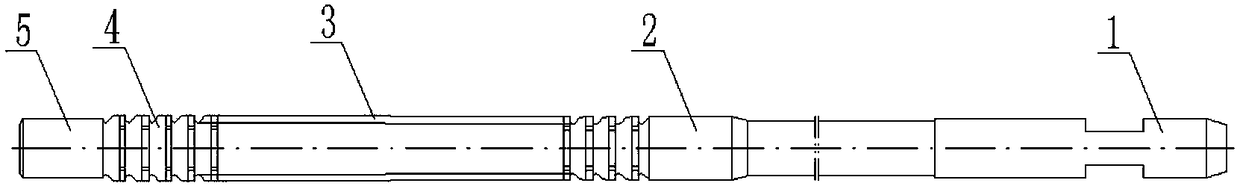

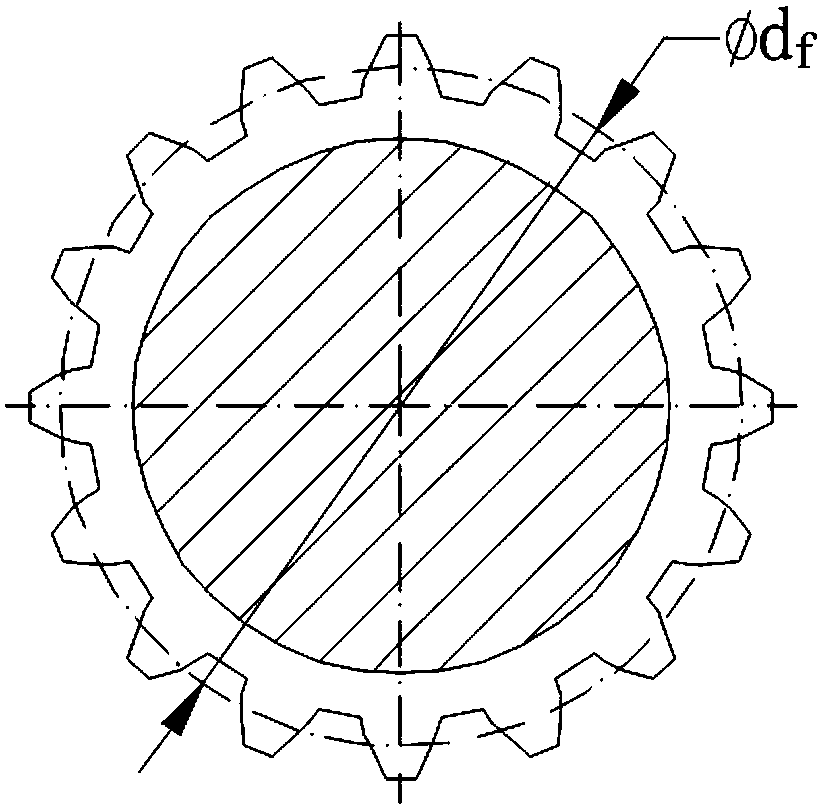

[0035] This embodiment provides a method for designing and manufacturing the teeth of an involute spline broach, the involute spline broach, such as figure 2 As shown, it includes a clamping part 1, a front guide part 2, a cutting tooth part 3, a correction tooth part 4 and a rear guiding part 5 along its axial direction. The correcting teeth of the correcting tooth section are distributed behind the cutting tooth section, and the correcting teeth have the same size and shape as the last cutting tooth, without taper. Therefore, as long as the cutter teeth of the cutting teeth are determined, the structure of the correcting teeth is also determined. Cutting teeth based on the Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com