High-precision automatic robot welding device and working method thereof

An automatic welding and robot technology, applied in the field of grid plates, can solve the problems affecting the quality of welding, difficult to complete the process, cumbersome operation, etc., to improve the accuracy of detection, solve the placement problem, and simplify the working process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

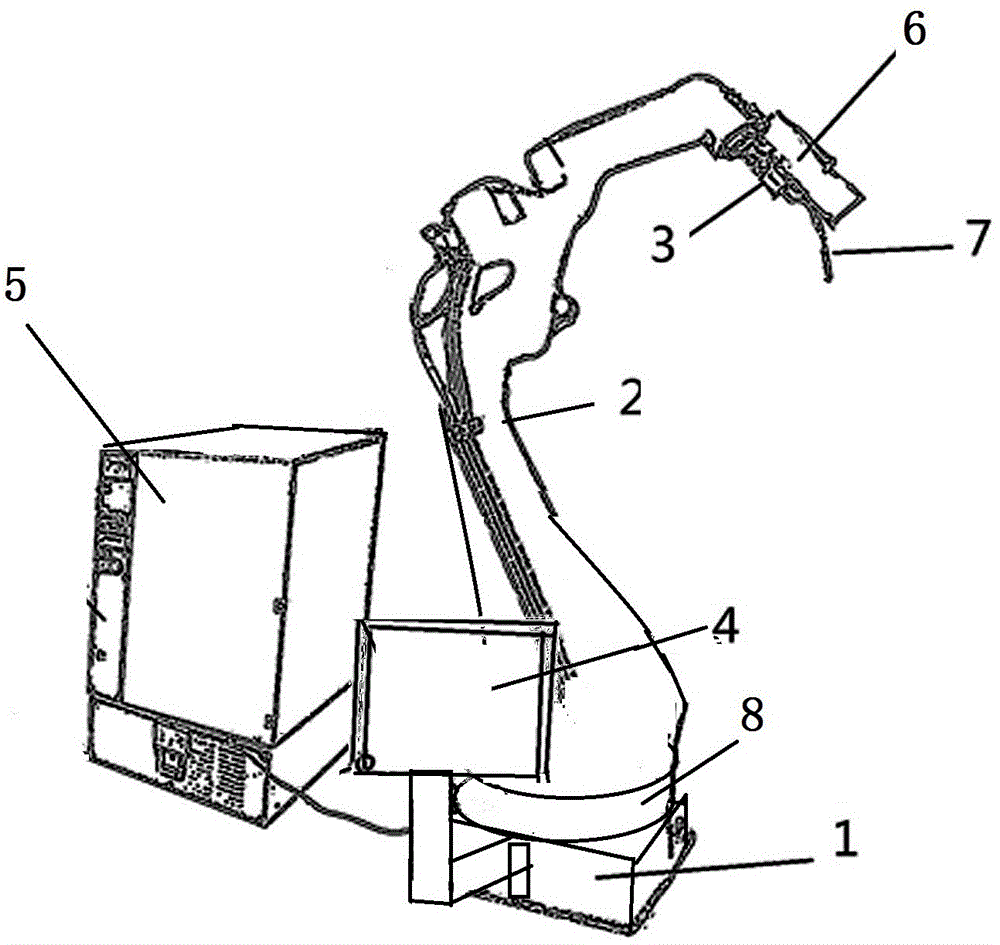

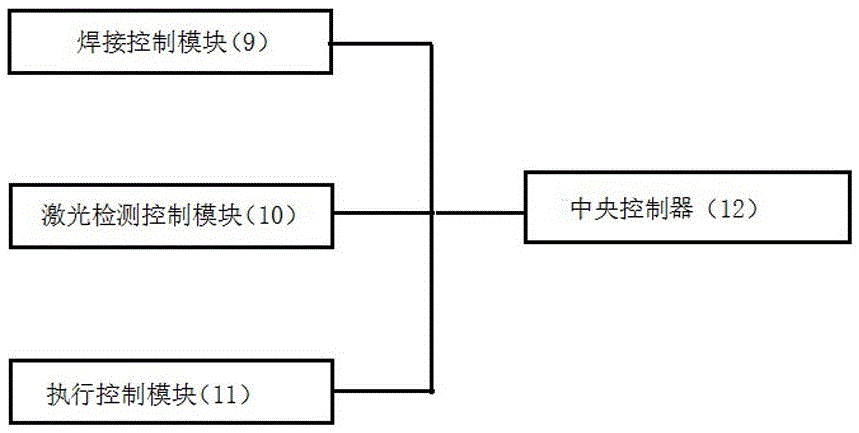

[0042] Such as Figure 1 to Figure 3 A high-precision robotic automatic welding device shown includes: a base 1, a mechanical arm 2, a wrist joint 3, a touch screen 4 and a control device 5, and the wrist joint 3 is provided with a laser detector 6 and a welding torch 7;

[0043] The relationship between the above components is as follows:

[0044] Wherein, the mechanical arm 2 is set on the base 1, the wrist joint 3 is set at the end of the mechanical arm 2, the touch screen 4 is set on the support frame of the base 1, the mechanical arm 2, wrist The joint 3, the touch screen 4 and the laser detector 6 are all connected to the control device 5, the control device 5 is provided with an electric control box, and the detection range of the laser detector 6 is greater than or equal to the required welding edge of the grid plate width.

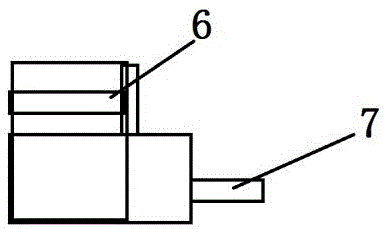

[0045] In this embodiment, the wrist joint 3 is provided with an installation base, and the installation base is in an inverted L shape. The in...

Embodiment 2

[0054] Such as Figure 1 to Figure 3 A high-precision robotic automatic welding device shown includes: a base 1, a mechanical arm 2, a wrist joint 3, a touch screen 4 and a control device 5, and the wrist joint 3 is provided with a laser detector 6 and a welding torch 7;

[0055] The relationship between the above components is as follows:

[0056] Wherein, the mechanical arm 2 is set on the base 1, the wrist joint 3 is set at the end of the mechanical arm 2, the touch screen 4 is set on the support frame of the base 1, the mechanical arm 2, wrist The joint 3, the touch screen 4 and the laser detector 6 are all connected to the control device 5, the control device 5 is provided with an electric control box, and the detection range of the laser detector 6 is greater than or equal to the required welding edge of the grid plate width.

[0057] In this embodiment, the wrist joint 3 is provided with an installation base, and the installation base is in an inverted L shape. The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com