Method for using welding jig of scrambling motorcycle frame back fork

A welding jig, motorcycle technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low work efficiency, unguaranteed welding quality, etc. The effect of precise location

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

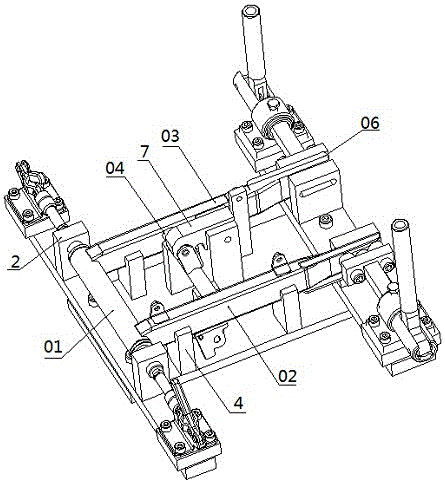

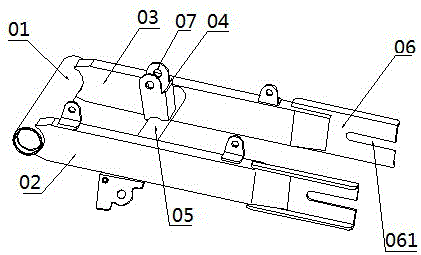

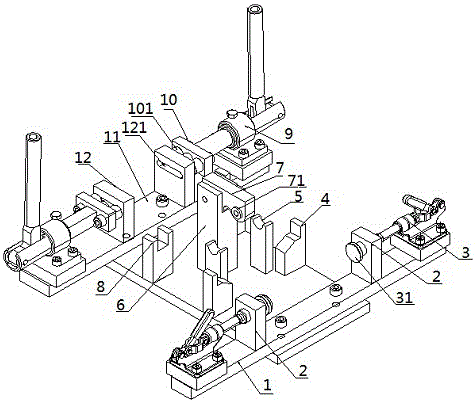

[0034] The method of using the welding fixture for the rear fork of the cross-country motorcycle frame of this embodiment includes the following steps:

[0035] Step 1: First adjust the position of the lifting lug positioning support 7 on the central fixed body 6 at the center of the cross-country motorcycle frame rear fork welding fixture so that the lifting lug positioning support 7 is perpendicular to the upper end surface of the tooling bottom plate;

[0036] Step 2: Position the parts of the rear fork of the cross-country motorcycle frame corresponding to the supports on the upper end surface of the tooling bottom plate;

[0037] Step 3: Push the quick chuck Ⅰ3 at both ends of the front backing plate 1 and insert the rear fork shaft positioning pin 31 on the top of the rear fork shaft positioning support 2 into the inner hole of the rear fork shaft 01;

[0038] Step 4: Push the quick chuck Ⅱ 9 at both ends of the back pad 11 to make the rear fork positioning pin 101 press the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com