White body trial manufacturing side wall integrated clamp and working method thereof

A working method and body-in-white technology, applied in the direction of manufacturing tools, metal processing equipment, auxiliary devices, etc., can solve the problems of increasing UNIT, increasing designer investment costs, craftsman planning costs, increasing drawing development, design costs, etc., to achieve reduction The effect of pre-process and increasing efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

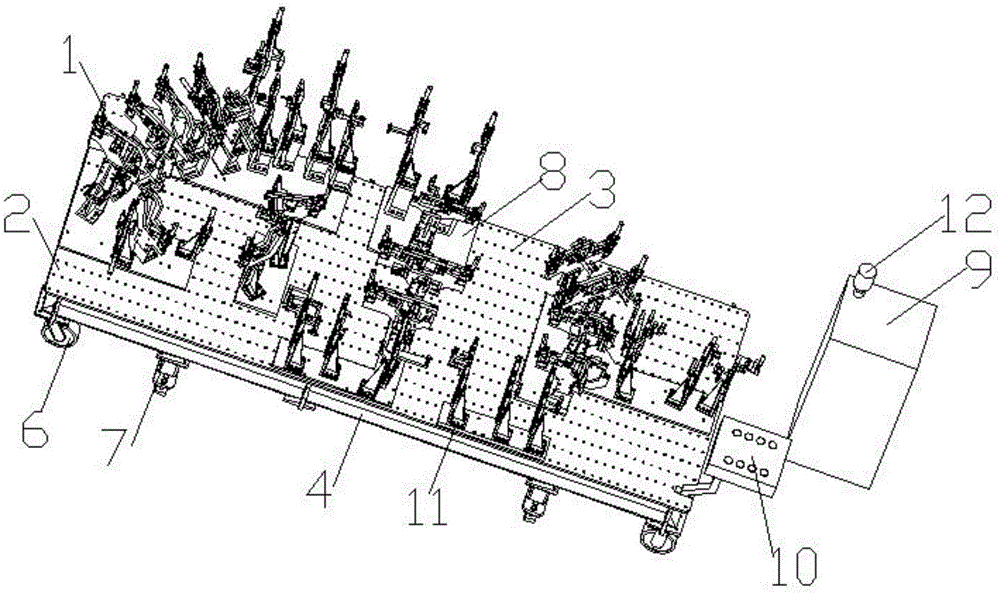

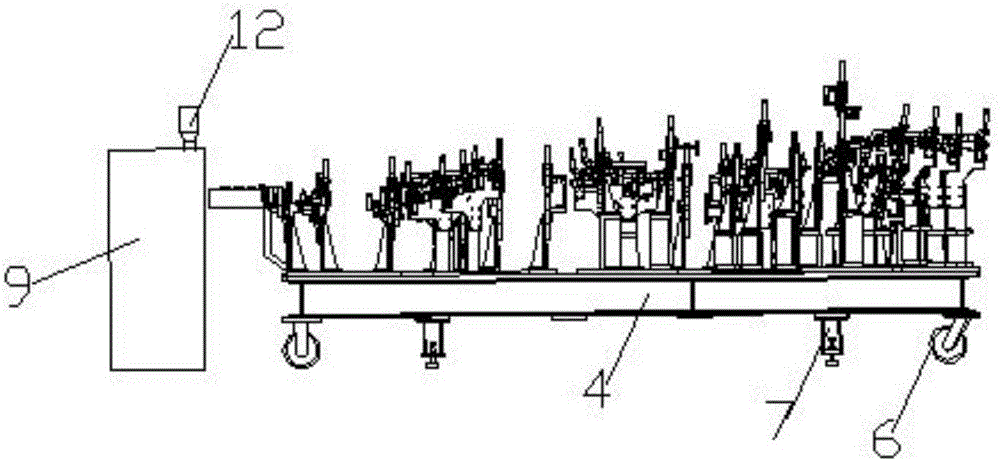

[0038] This embodiment provides a body-in-white trial-manufactured side enclosure integrated fixture, including: UNIT unit, BASE board, BASE flexible hole, angle steel, transition board, electrical control cabinet, manual operation box, travel sensor, alarm,; the UNIT unit is located On the transition plate, the transition plate is fixed on the BASE plate, the BASE plate is provided with BASE flexible holes, the angle steel is installed at the bottom of the BASE plate, hooks are provided at the four corners of the angle steel, and universal wheels are provided at the four corners of the bottom of the angle steel , the manual operation box is placed on one side of the BASE board; the electrical control cabinet is arranged on the side of the BASE board; the alarm is installed above the electrical control cabinet, and the UNIT unit is provided with a stroke sensor.

[0039] Preferably, the above-mentioned fixture further includes leveling feet; there are four leveling feet; they a...

Embodiment 2

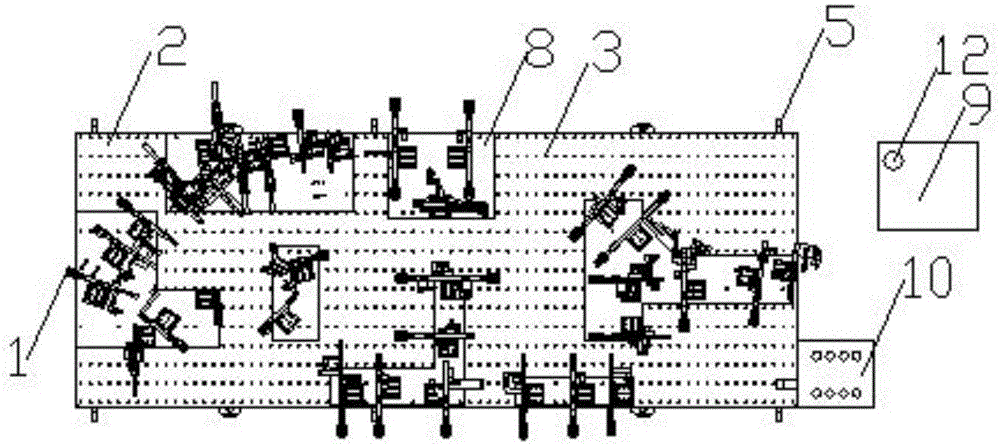

[0054] This embodiment provides a working method for the integrated fixture of the trial-manufactured side wall of the body-in-white: the tooling for the trial-manufacture of the side wall of the body-in-white includes: B-pillar inner panel assembly, D-pillar inner panel assembly, side wall inner panel assembly, side wall Outer panel assembly, side wall assembly; the following combination is as follows Figure 4 The schematic diagram of the UNIT unit layout is shown for illustration. According to different process parts, the layout of the UNIT unit may change.

[0055] 1) When welding the B-pillar inner panel assembly, press the B-pillar one-button up start button, and the electrical control cabinet controls the UNIT unit (E, F, G, H, I, Y, Z, AA, AC, AD) to automatically Lift up and position and assemble the parts, where the lifting height = the thickness of the outer panel of the side wall + the thickness of the reinforcement plate of the B-pillar of the side wall (which has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com