Leak detection robot for SF6 gasin substation GIS equipment

A SF6, substation technology, used in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of complex terrain, complicated equipment, and increased investment costs on the detection site. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

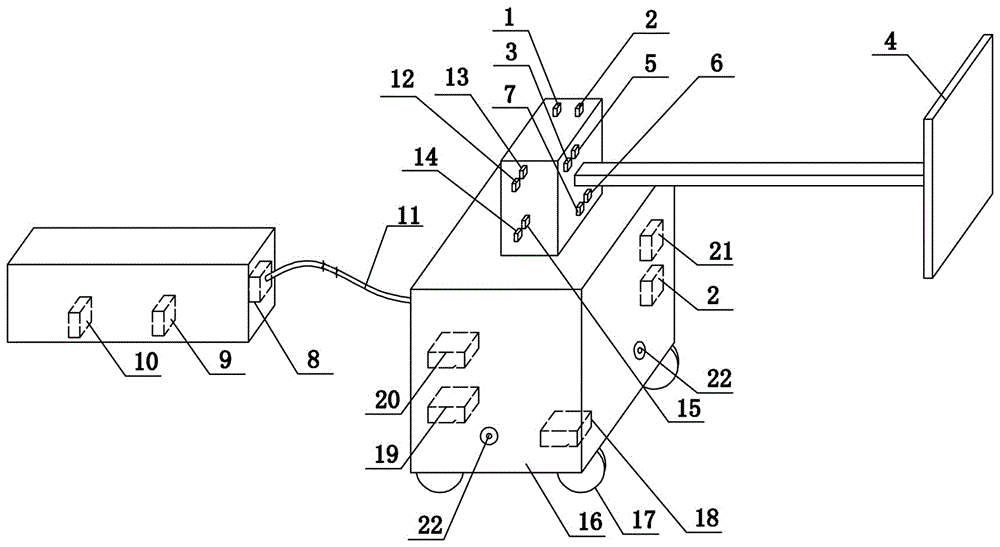

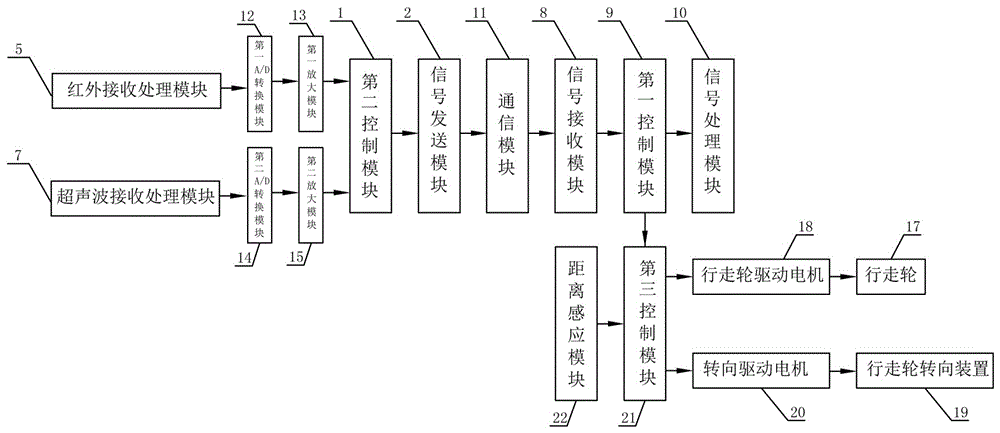

[0032] like Figure 1 to Figure 4 As shown, the present invention includes a remote control device, a running device and a gas directional leak detection device arranged on the running device, and the remote control device includes a signal receiving module 8, a first control module 9 and a signal processing module 10 electrically connected in sequence;

[0033] The gas directional leak detection device includes an infrared detection module, an ultrasonic detection module, a second control module 1 and a signal transmission module 2. The infrared detection module includes an infrared transmission module 3, an infrared reflector 4 and an infrared receiving and processing module 5. The ultrasonic detection module includes an ultrasonic Transmitting module 6 and ultrasonic receiving processing module 7, the output end of infrared receiving processing module 5 and ultrasonic receiving processing module 7 are electrically connected with the input end of second control module 1 respe...

Embodiment 2

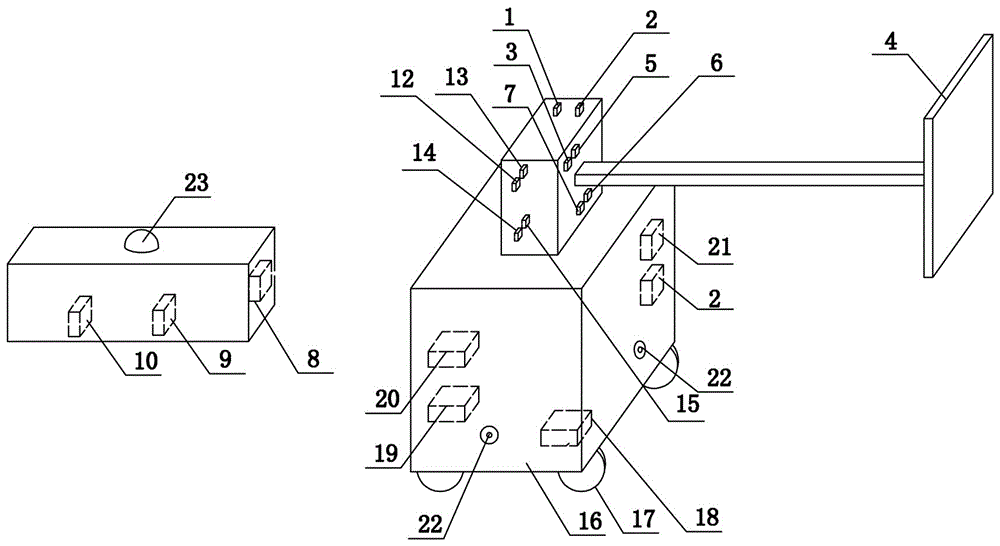

[0036] The structure of this embodiment is basically the same as that of Implementation 1. The difference is that the walking device is placed on the GIS equipment site for long-term use, and the signal sending module 2 and the signal receiving module 8 communicate through the communication module 11, and the communication module 11 is a ZigBee communication module. , the infrared detection module and the ultrasonic detection module adopt intermittent work to improve the working stability and service life of the sensor. The output end of the first control module 9 is also electrically connected to the alarm module 23, and the alarm module 23 adopts an audible and visual alarm. The output end of the control module 1 is also electrically connected to the exhaust fan (not shown in the figure) on the site of the GIS equipment.

Embodiment 3

[0038] The structure of this embodiment is basically the same as that of implementing one, and the difference is: a camera module 24 is set on the support 16, and the input end of the camera module 24 is connected with the third control module 21, and the camera module 24 sends the real-time video signal of the scene to the third control module 21. Three control modules 21, the third control module 21 sends the video signal to the first control module 9, and displays it to the on-site management personnel through the signal processing module 10. This structural design is conducive to observing the real scene of the air leakage on site, especially for the location of the air leakage provide a basis for judgment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com