Electric chain saw

A technology of electric chainsaws and chainsaws, which is applied in the direction of chainsaws, sawing components, sawing equipment, etc., and can solve problems such as accidental startup of electric chainsaws, and achieve the effects of saving manpower, simple structure, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

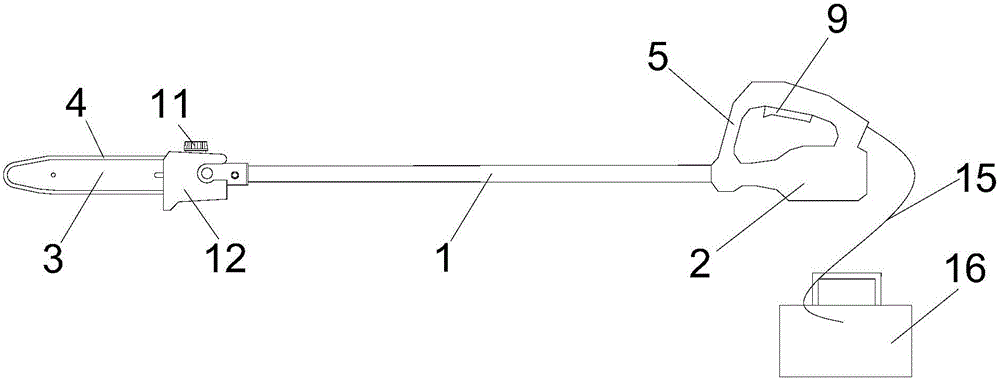

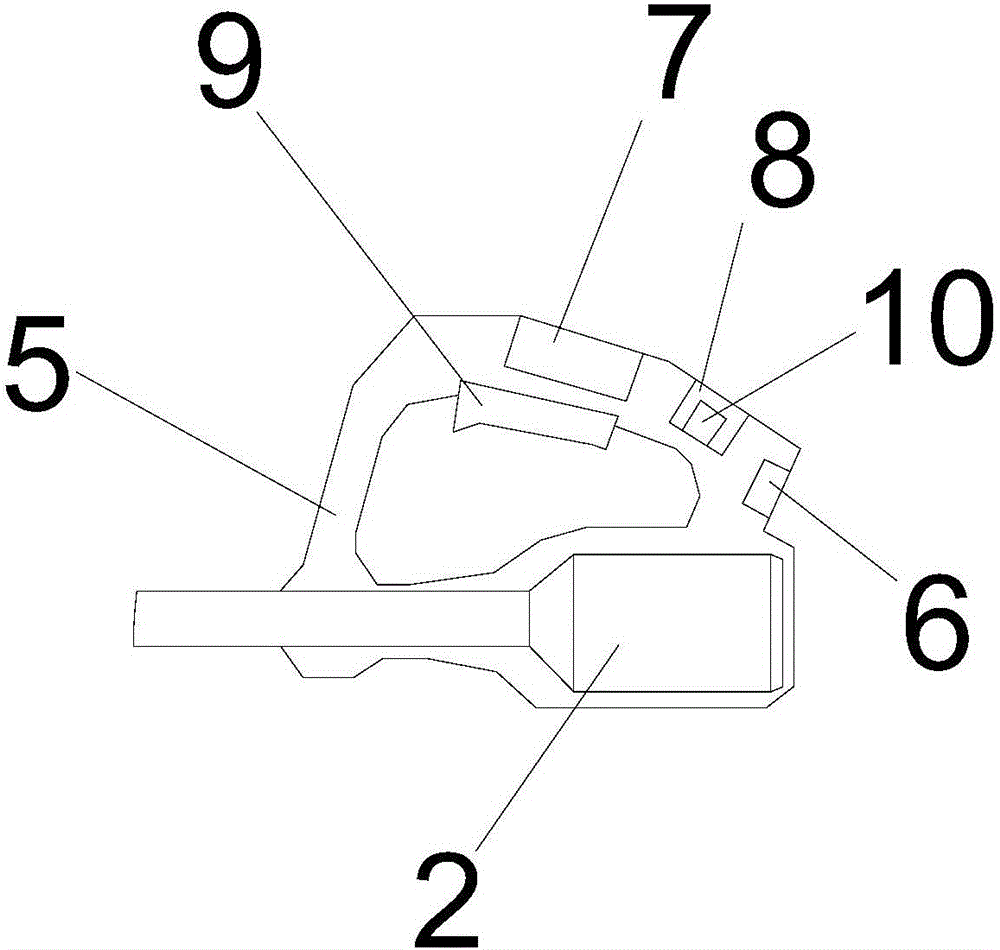

[0030] Such as figure 1 and image 3 An electric chain saw includes a power assembly, a transmission rod 1 and a cutting assembly; one end of the transmission rod 1 is connected to the power assembly, and the other end of the transmission rod 1 is connected to the cutting assembly. The power assembly includes a motor 2 and a motor housing, the motor housing is installed on the transmission rod 1, and the motor 2 is located in the motor housing; the inside of the transmission rod 1 is provided with a transmission shaft , the material of the transmission rod 1 is aluminum alloy, and the transmission rod 1 is provided with a cushion to facilitate hand holding. The cutting assembly includes a gear box, a guide plate 3 and a chain saw 4; the gear box is also provided with a lubricating oil pot 11 made of translucent plastic, and the bottom of the lubricating oil pot 11 is provided with an extrusion opening. The motor 2 is connected to the gear box through the transmission shaft; ...

Embodiment 2

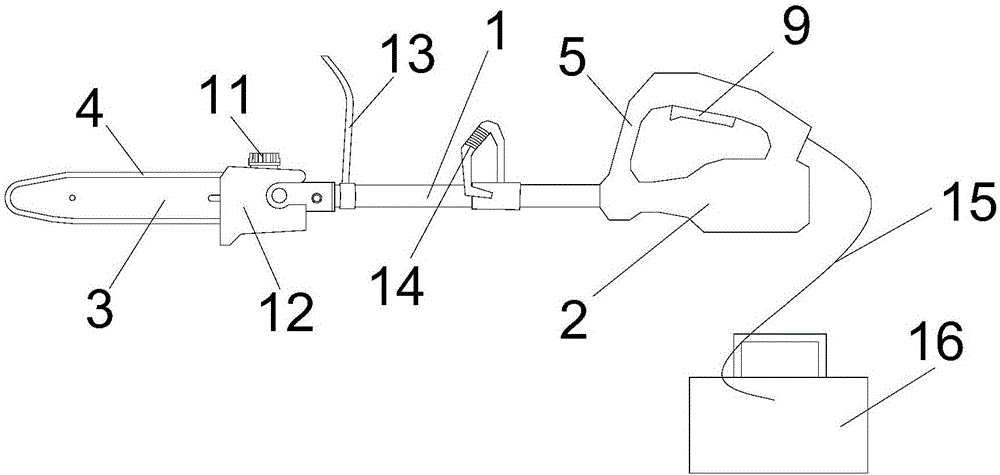

[0032] Such as figure 2 and image 3 , the structure and principle of the electric chain saw provided in embodiment 2 are roughly the same as the electric chain saw in embodiment 1, except that in this embodiment, the transmission rod 1 is made of stainless steel and is a short rod, A handguard baffle 13 and a handrail 14 are arranged at intervals on the transmission rod 1 , the handguard 13 is located between the cutting assembly and the handrail 14 , and the handrail 14 is provided with anti-slip protrusions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com