Inversion type restricted ultraviolet light 3D (three-dimensional) printer

A three-dimensional printer and ultraviolet light technology, which is applied in the directions of additive manufacturing, 3D object support structure, manufacturing tools, etc., can solve the problems of low printing performance, low printing accuracy, and uneven thickness of printing layers, and achieve printing accuracy. High, uniform layer thickness, guaranteed performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

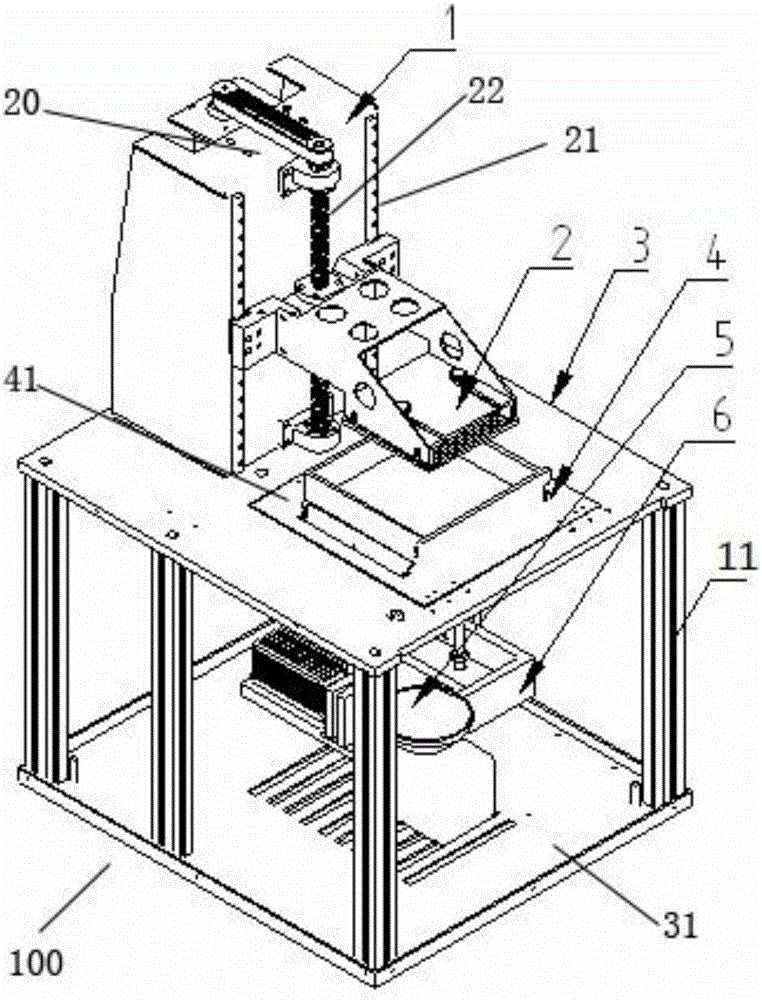

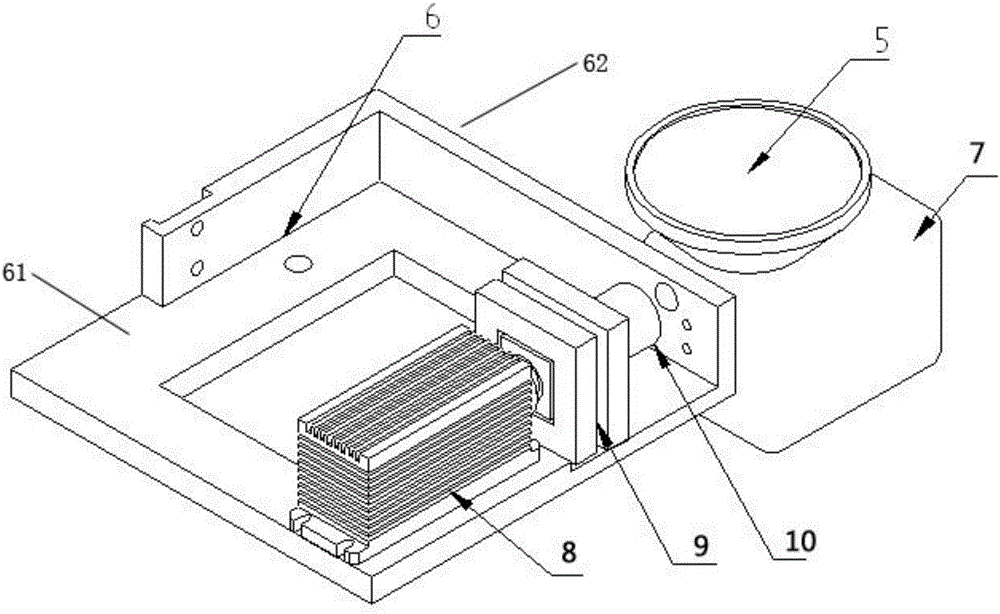

[0021] like figure 1 , 2 As shown, an inverted constrained ultraviolet three-dimensional printer includes a frame 100, the frame 100 includes an upper base 3 and a lower base 31, and a plurality of support columns 11 are arranged between the upper base 3 and the lower base 31, the structure except It has stable support, sufficient strength, rigidity and stability, thus ensuring the stability of the laser system and improving the printing performance. The support column 11 includes six aluminum profile support columns, and vibration instability will not occur.

[0022] One side of the upper base 3 is provided with a column 1, the column 1 is perpendicular to the upper base 3, the column 1 is a frame type column 1, a lifting mechanism 20 is fixed on one side of the column 1, and a curing workbench 2 is fixed on the lifting mechanism 20, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com