Dual-motor parallel serial driving module and vehicle

The technology of a drive module and dual motors is applied to a vehicle with the drive module. , In the field of dual-motor hybrid drive modules, it can solve the problems of easy wear, large motor size, and low reliability, and achieve the effects of high efficiency, high reliability, and guaranteed safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

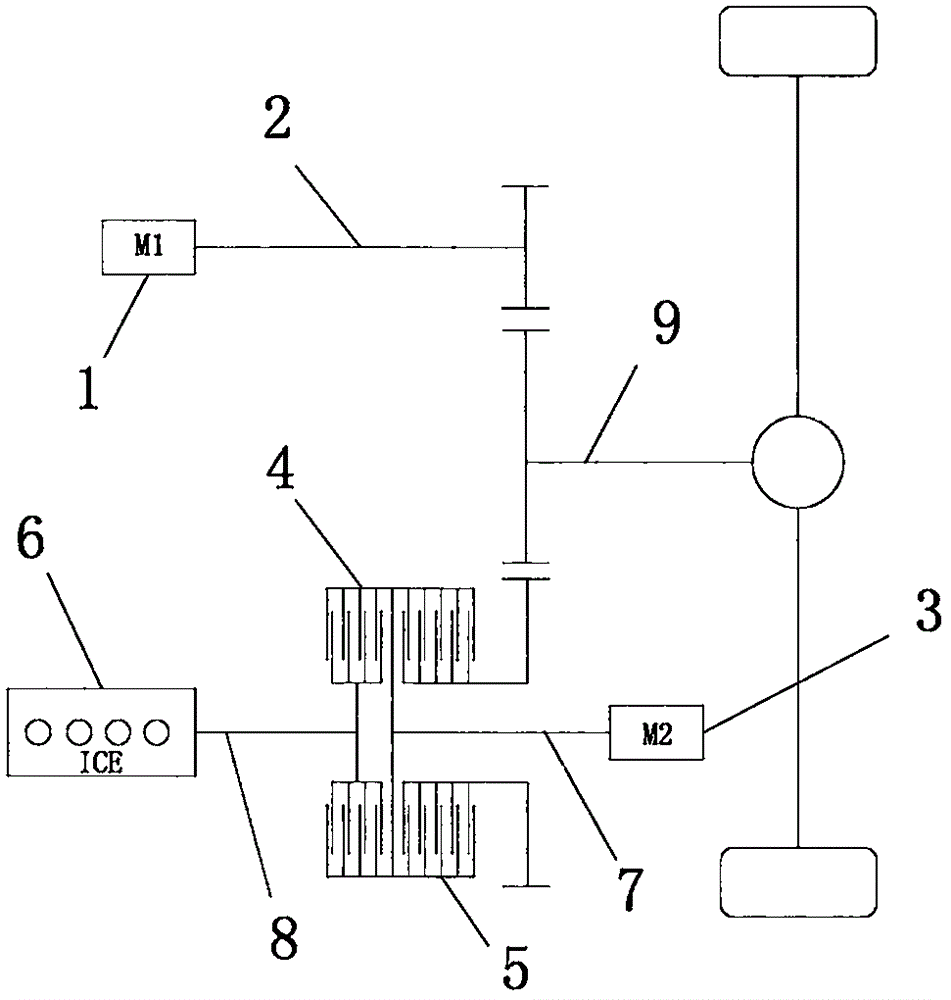

[0025] The first dual-motor hybrid drive module includes a first input shaft 2, a second input shaft 7, and a third input shaft 8 parallel to each other. One end of the first input shaft 2 is connected to a main drive motor 1, and the The first input shaft 2 is connected to the output shaft 9 through a pair of reduction gears, that is, the radius of the gear connected to the output shaft 9 is larger than the radius of the gear connected to the first input shaft 2 .

[0026] Two integrated clutches are connected to the second input shaft 7, and the clutches are wet clutches, consisting of a first clutch 4 and a second clutch 5, wherein the first clutch 4 and the second clutch 5 share A housing, the inside of the housing is connected with evenly distributed steel plates, the steel plates of the first clutch 4 and the second clutch 5 are separated by the hub, friction plates are arranged between the steel plates, and the friction plates of the first clutch 4 are connected as One,...

Embodiment 2

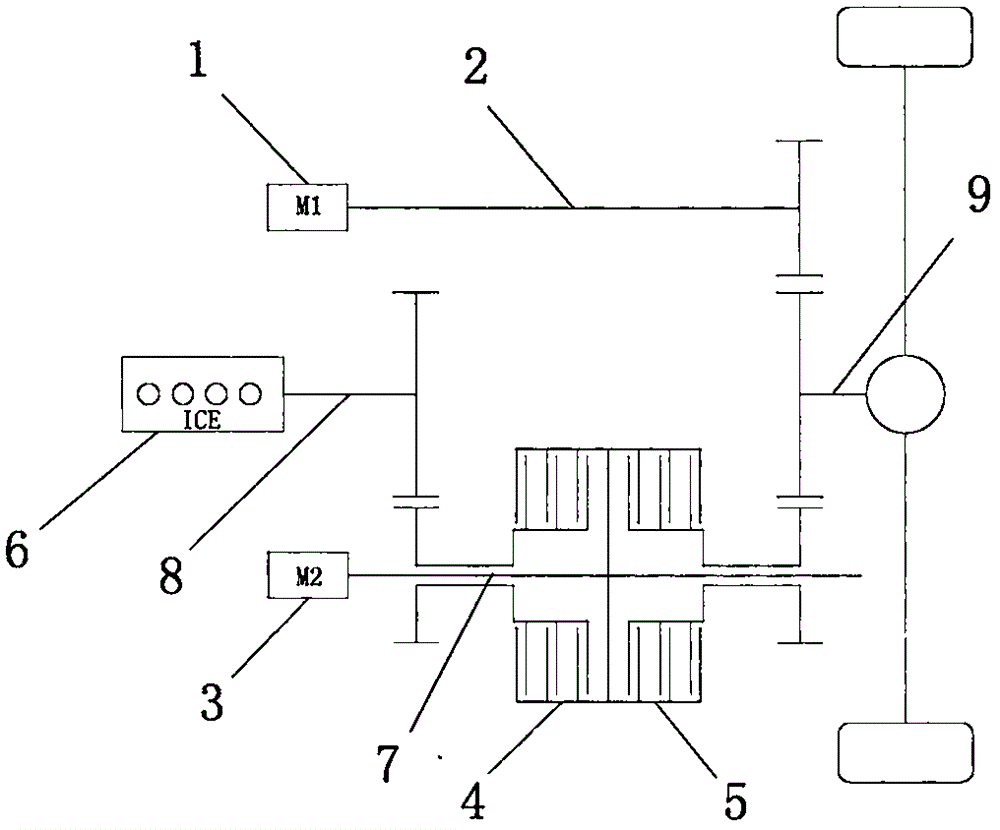

[0049] The second dual-motor hybrid drive module includes a first input shaft 2, a second input shaft 7 and a third input shaft 8 parallel to each other, one end of the first input shaft 2 is connected with a main drive motor 1, and the The first input shaft 2 is connected to the output shaft 9 through a pair of reduction gears, that is, the radius of the gear connected to the output shaft 9 is larger than the radius of the gear connected to the first input shaft 2 .

[0050] Two integrated clutches are connected to the second input shaft 7, and the clutches are wet clutches, consisting of a first clutch 4 and a second clutch 5, wherein the first clutch 4 and the second clutch 5 share A housing, the inside of the housing is connected with evenly distributed steel plates, the steel plates of the first clutch 4 and the second clutch 5 are separated by the hub, friction plates are arranged between the steel plates, and the friction plates of the first clutch 4 are connected as On...

Embodiment 3

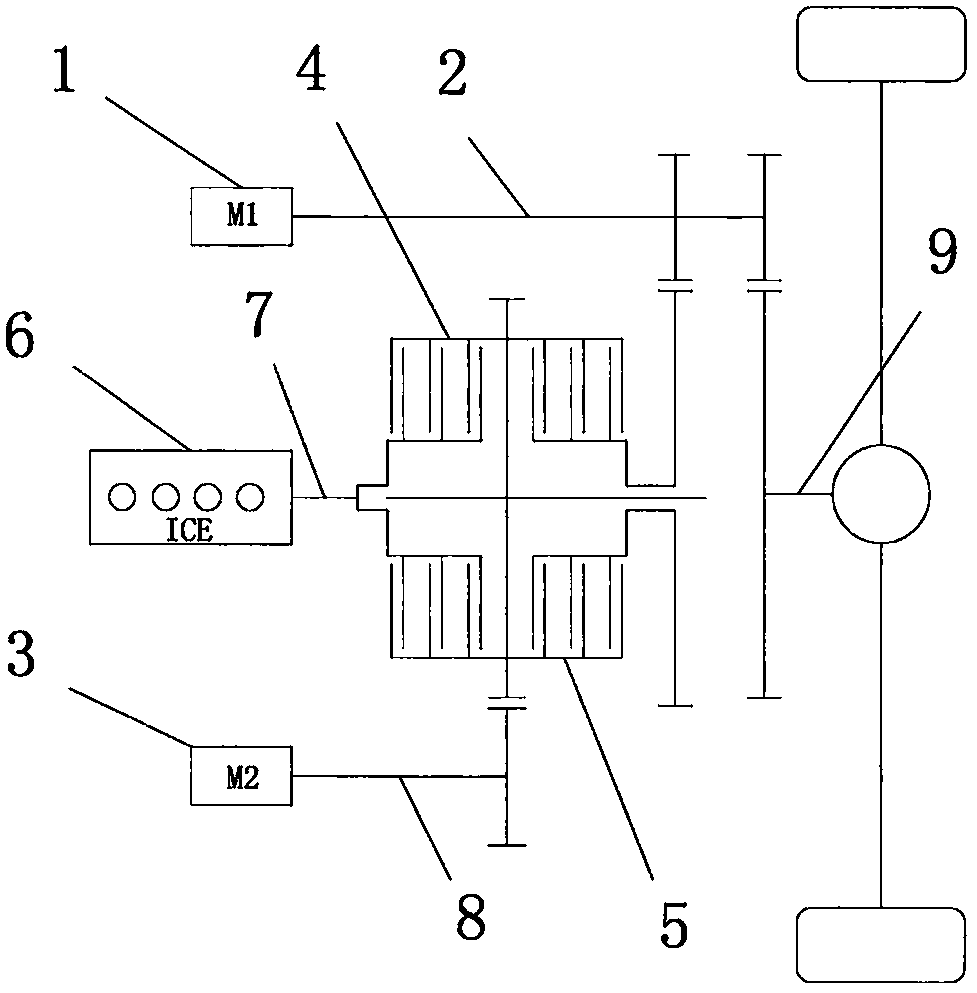

[0070] A dual-motor hybrid drive module, the main drive motor 1 is connected to the first input shaft 2, and the first input shaft 2 and the output shaft 9 are connected through a meshed reduction gear pair to provide the first output power for the output shaft 9 The second input shaft 7 parallel to the first input shaft 2 is connected with the output shaft 9 through a gear pair, and two integrated clutches are connected on the second input shaft 7, the ISG motor 3 and the engine 6 provides the second power output for the output shaft 9 by connecting with the clutch.

[0071] The clutch is a wet clutch, which is composed of a first clutch 4 and a second clutch 5; wherein, the first clutch 4 and the second clutch 5 share a housing, and evenly distributed steel plates are connected inside the housing. The steel plates of the clutch 4 and the second clutch 5 are separated by the wheel hub, friction plates are arranged between the steel plates, the friction plates of the first clu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com