Automobile decoupling distributed braking system pure electric brake actuator

A braking system and actuator technology, applied in electric braking systems, electric vehicles, collectors, etc., can solve problems such as brake thermal decay, brake wear, and inability to shunt currents, and achieve rapid dynamic response, prevent overheating, Good resistance to failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

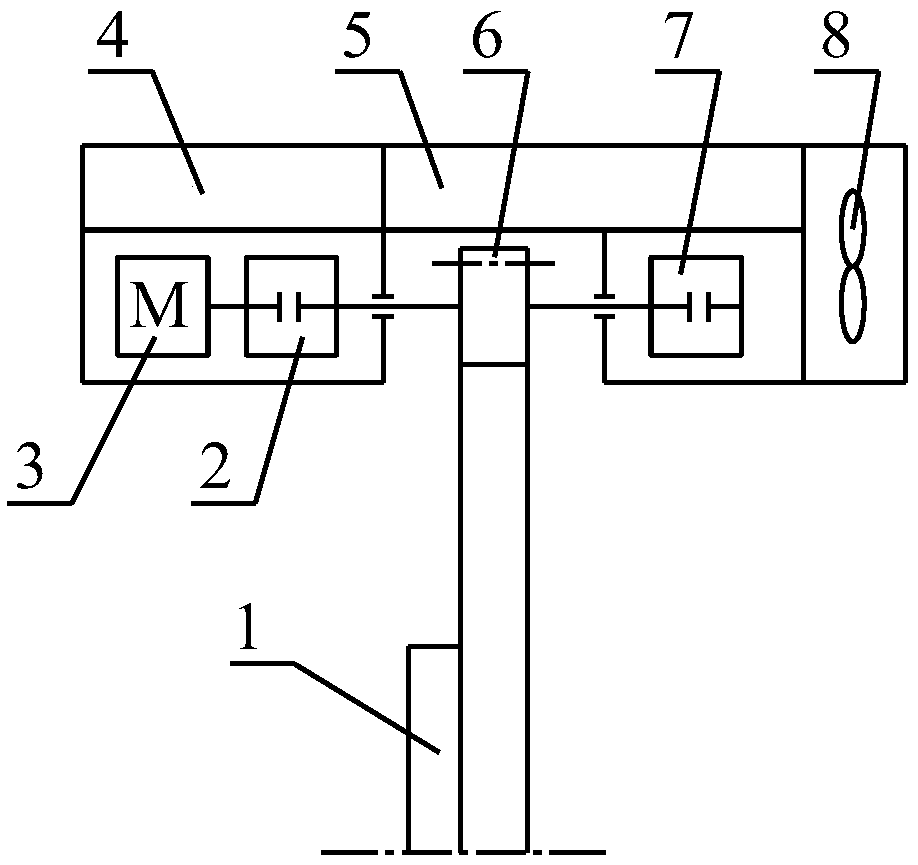

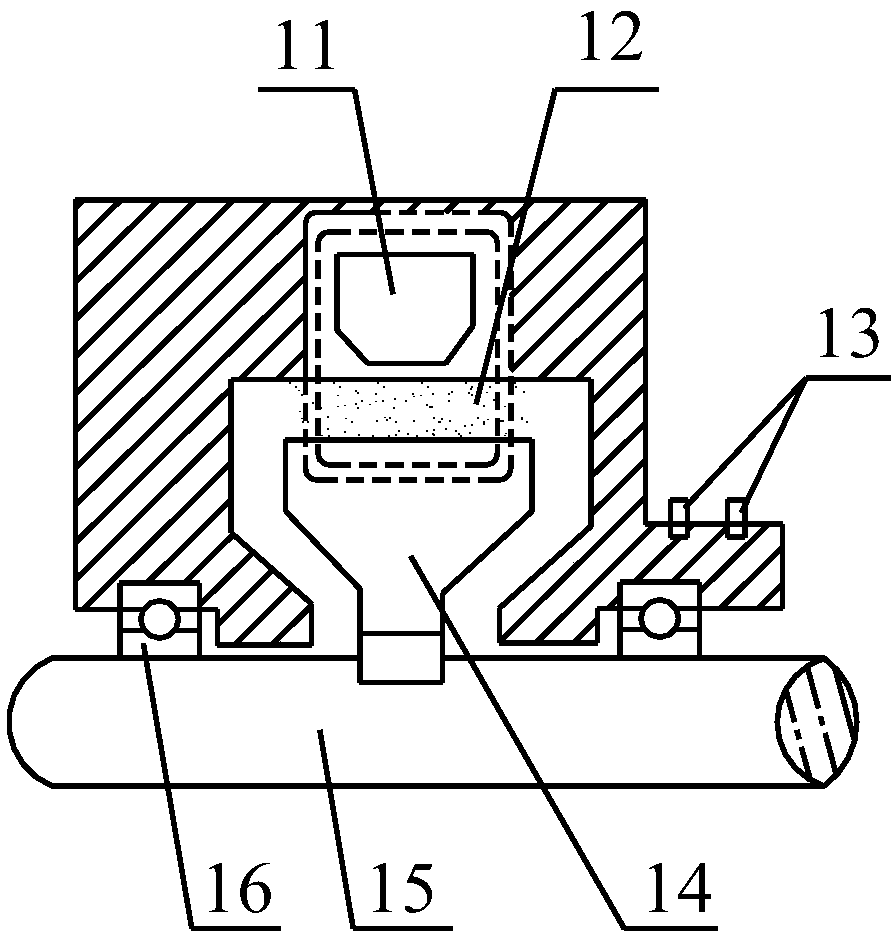

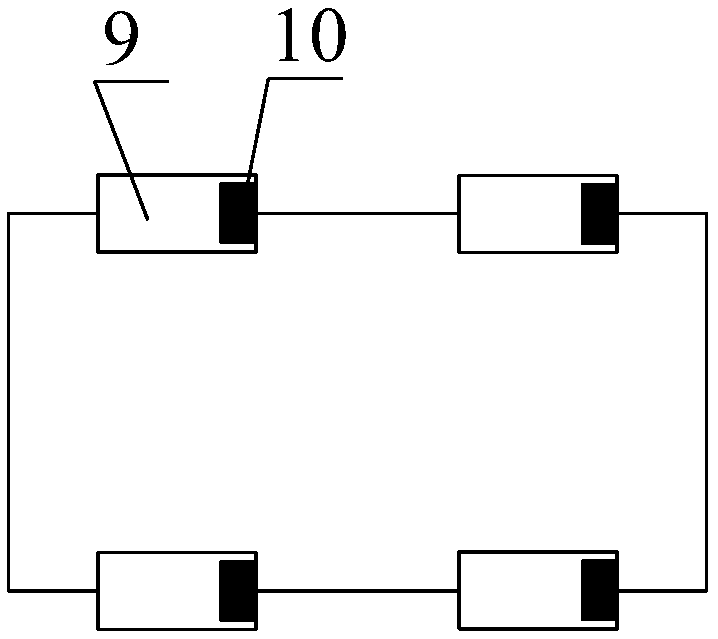

[0023] like figure 1 As shown, a pure electric brake actuator includes a brake disc 1, an electromagnetic clutch 2, an electromagnetic brake 7, a battery pack 5 and an electronic control unit 4, and the circumferential surface of the brake disc 1 is provided with a ring gear , the brake disc 1 is meshed with a pinion 6 through the ring gear, and the pinion 6 drives the input shaft 15 of the electromagnetic clutch and the input shaft of the electromagnetic brake 7 to rotate; the driven part of the electromagnetic clutch 2 is connected with The regenerative motor 3, the battery pack 5 are electrically connected to the electromagnetic clutch 2 and the electromagnetic brake 7, and the electronic control unit 4 is used to control the connection between the electromagnetic clutch 2 and the battery pack 5 and the electromagnetic brake 7 and the battery pack 5. circuit on and off; the regenerative motor 3 is electrically connected to the battery pack 5, and the electronic control unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com