Pressurization gas cylinder arrangement method in rocket oxygen tank cold helium pressurization system

A rocket oxygen tank and pressurization system technology, applied in the direction of aerospace vehicle propulsion system devices, etc., can solve the problems of no cold helium pressurization technology patent, lack of cold helium pressurization technology, etc., to improve the rocket carrying capacity and reduce the increase The effect of the amount of helium used for pressure and high safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

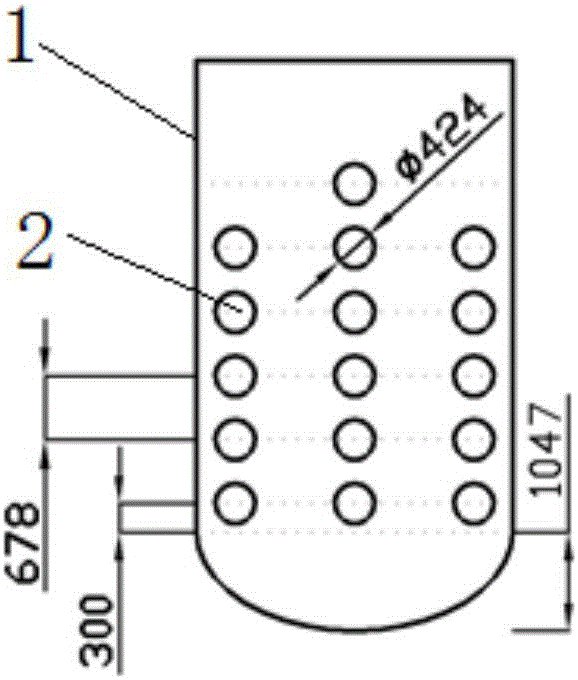

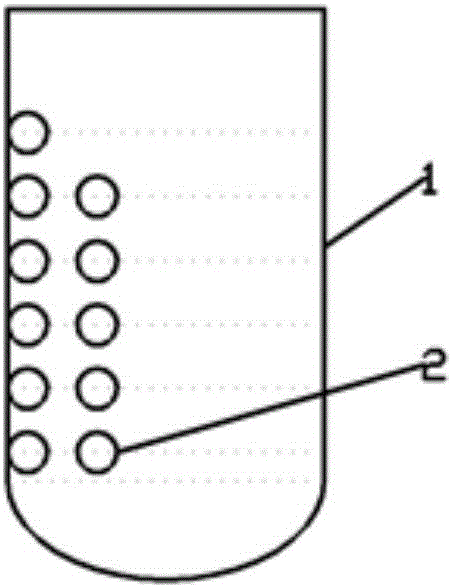

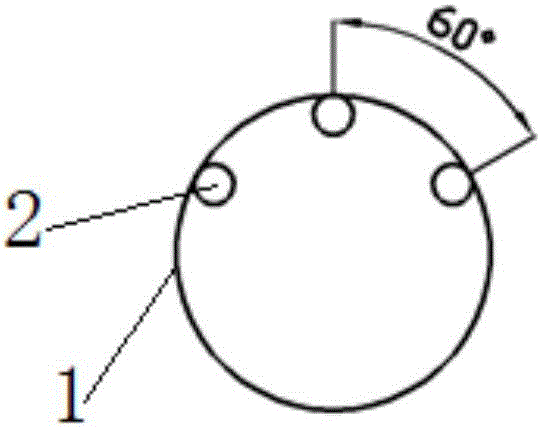

[0026] A method for arranging pressurized gas cylinders in a cold helium pressurized system of a rocket oxygen tank, such as Figure 1-Figure 3 As shown, 16 cold helium cylinders are arranged in rows in the inner cylinder section of the oxygen box, and the 16 cold helium cylinders are arranged in 3 rows, and the number of cold helium cylinders in each row is 5, 6, and 5 respectively. The 16 cold helium cylinders 2 also form a layered arrangement, with a total of 6 floors. There are 3 cold helium cylinders 2 on each of the lower 5 floors, and the top cold helium cylinder 2 contains 6 cold helium cylinders. on the column of bottle 2. 3 cold helium cylinders 2 on each floor are 60° apart on the oxygen box 1 circumference. The plane at the center of the bottom three cold helium cylinders 2 is 300mm from the rear equator of the oxygen box 1. The interval between the two layers of cold helium cylinders 2 connected is 678mm. The cold helium cylinder 2 is arranged close to the wall...

Embodiment 2

[0030] The specific steps of the cold helium cylinder filling process are as follows:

[0031] 1. Before the rocket is launched, the filling of liquid oxygen in the oxygen tank 1 is completed, and the initial temperature of the liquid oxygen is 90K;

[0032] 2. The cold helium cylinder 2 starts to fill with helium, the filling temperature of helium is 80K, and the filling flow rate is 0.02kg / s;

[0033] 3. The cold helium cylinder 2 is filled with helium to 23MPa, and the helium is continuously replenished to maintain 23MPa during parking.

[0034] According to the simulation calculation, under the column arrangement, the cold helium cylinder reaches 23MPa after 2800s, and it takes 3200s for the temperature and pressure inside the cylinder to stabilize. The maximum temperature of the cylinder is 93.71K, and the maximum heat transfer between the cylinder and liquid oxygen is 4222W .

Embodiment 3

[0036] The specific steps of the pressurization process are as follows:

[0037] 1. The pressure annunciator detects the pressure of the air pillow in the oxygen tank 1. When the pressure of the air pillow is lower than the rated value, the controller opens the solenoid valve on the booster pipeline, and the low-temperature and high-pressure helium comes from 16 cold helium cylinders 2 connected in parallel. Output, helium flow rate 0.26kg / s;

[0038] 2. Helium is decompressed through the pressure reducer, and the throttle coil controls the flow;

[0039] 3. Helium enters the heater and heats up to about 500K;

[0040] 4. The decompressed and heated helium enters the air pillow of the oxygen box 1 for pressurization.

[0041] According to the simulation calculation, the pressure in the oxygen tank is basically maintained at 0.32MPa in view of the row-like arrangement of gas cylinders. The pressure fluctuates greatly at the beginning, and then gradually stabilizes; the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com