Medical sealing machine provided with bidirectional operation handle

A two-way operation, sealing machine technology, used in packaging sealing/fastening, external support, transportation packaging, etc., can solve problems such as sealing failure, damage to sealing paper, affecting sealing effect, etc., to prevent uneven sealing and prevent overburning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

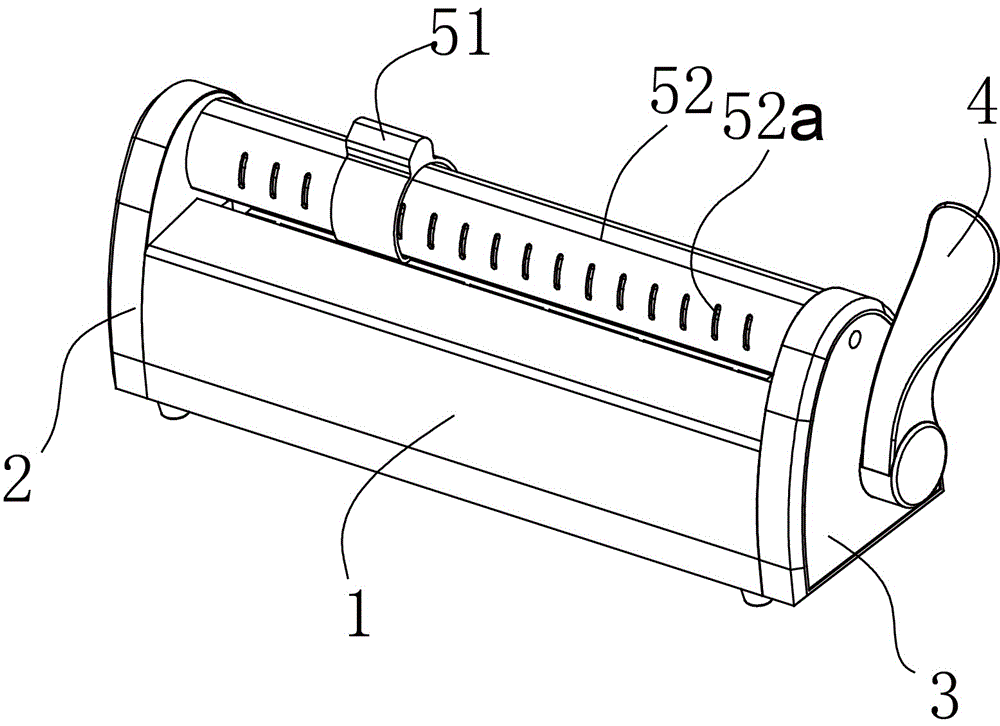

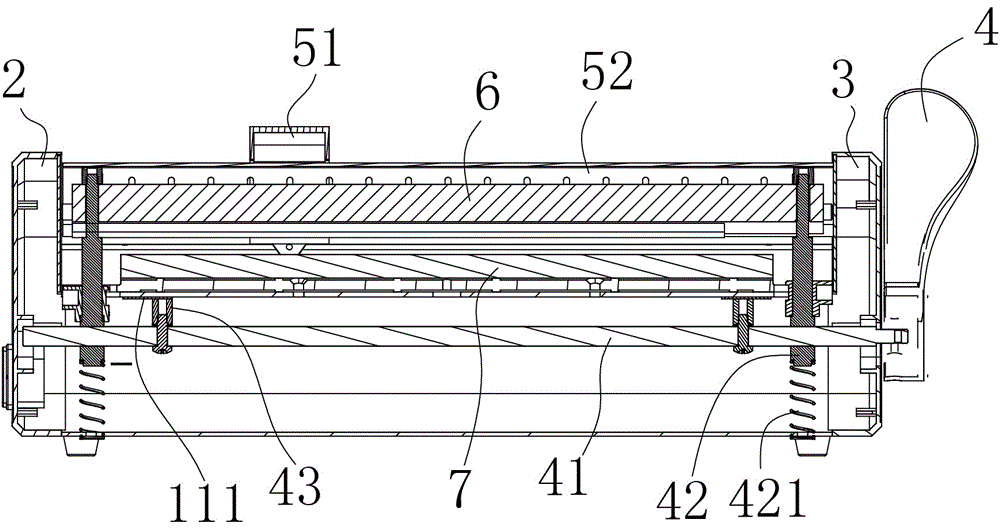

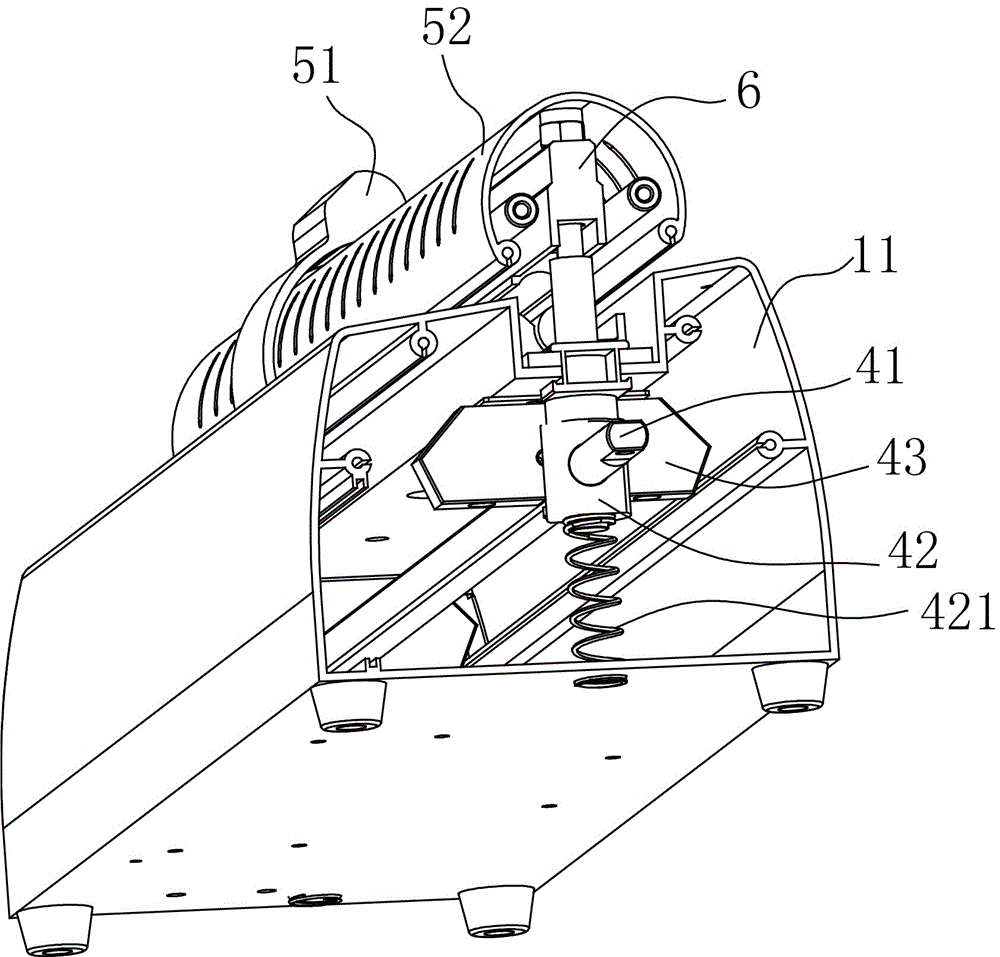

[0032] Attached Figure 1 to Attached Figure 15 The reference signs in are: 1 sealing machine main body, 11 casing, 11a heating groove, 11b first card groove, 11d screw seat, 111 baffle plate, 2 left guard plate, 2a left guide groove, 3 right guard plate, 3a Right guide slot, 4 handle, 41 driving rod, 41a cylinder part, 41b square column part, 42 follower rod, 421 spring, 423 rod head, 423a shaft hole, 424 shaft, 425 fastening nut, 43 skid plate, 43a Skid surface, 43b fourth card slot, 43c screw hole, 43d stress relief groove, 43e stress relief hole, 43f fastening screw, 43g rubber pad, 43k lever assembly, 51 slider, 51a first guide hole, 51b, second Guide hole, 51c third guide hole, 51d ironing surface, 511 blade, 52 guide rail, 52a heat dissipation grid, 52b inner rail, 52c reinforcement rail, 52d heat dissipation cavity, 6 layering strips, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com