A kind of ceramic membrane and preparation method thereof, ceramic membrane module, waste water treatment system

A wastewater treatment system and ceramic membrane technology, applied in water/sewage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of inability to exert catalytic activity, complex structure, ceramic membrane pollution, etc. Achieve the effect of speeding up the oxidation reaction rate, improving the reaction efficiency and shortening the mass transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

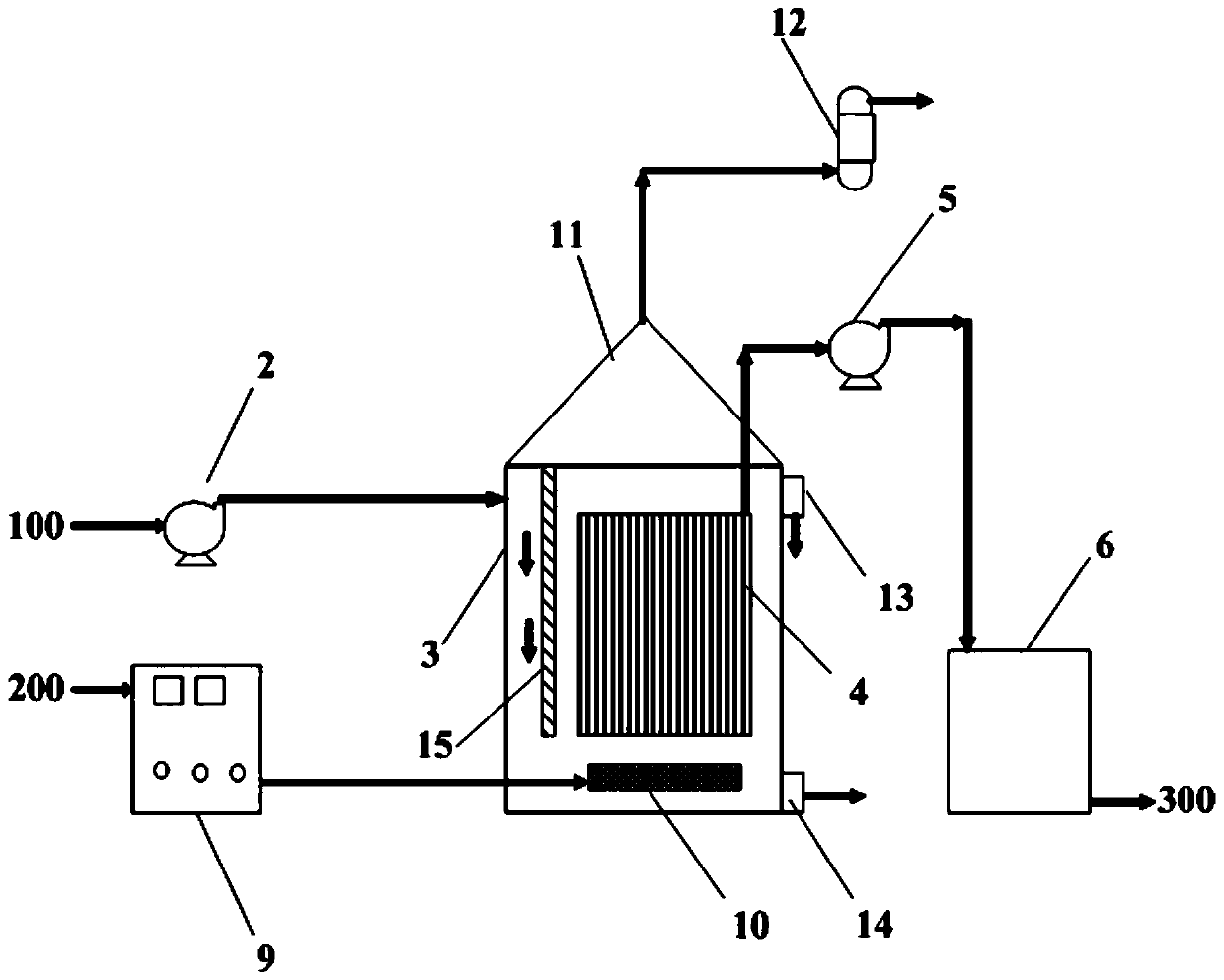

[0028] Experimental example: preparation of ceramic membrane: ceramic particles are processed into tiny ceramic particles with nanoscale characteristics, and the particle size is 200nm. The manganese dioxide is processed into particles with nanoscale characteristics, and the particle size is 260nm. Then, the ceramic particles and the manganese dioxide particles are mixed according to the mass ratio of 100:2, and are sintered at a high temperature of 1200°C to bond them to form a sintered body to obtain a ceramic film. Such as figure 2 Shown is the scanning electron microscope image of the prepared ceramic membrane. It can be seen from the figure that the average diameter of the pore channel in the microstructure of the ceramic membrane is 50 nm, and the length of the prepared pore channel is 2 mm.

[0029] The ceramic membrane was formed into a flat plate with a length of 1200 mm, a width of 300 mm, and a thickness of 6 mm. The prepared multiple flat ceramic membranes are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com