Bucket-free reverse osmosis water purifier system capable of improving water production rate and control method

A technology of reverse osmosis water purifier and water production rate, applied in water treatment parameter control, water/sewage treatment, chemical instruments and methods, etc. Low cost, high achievable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with accompanying drawing:

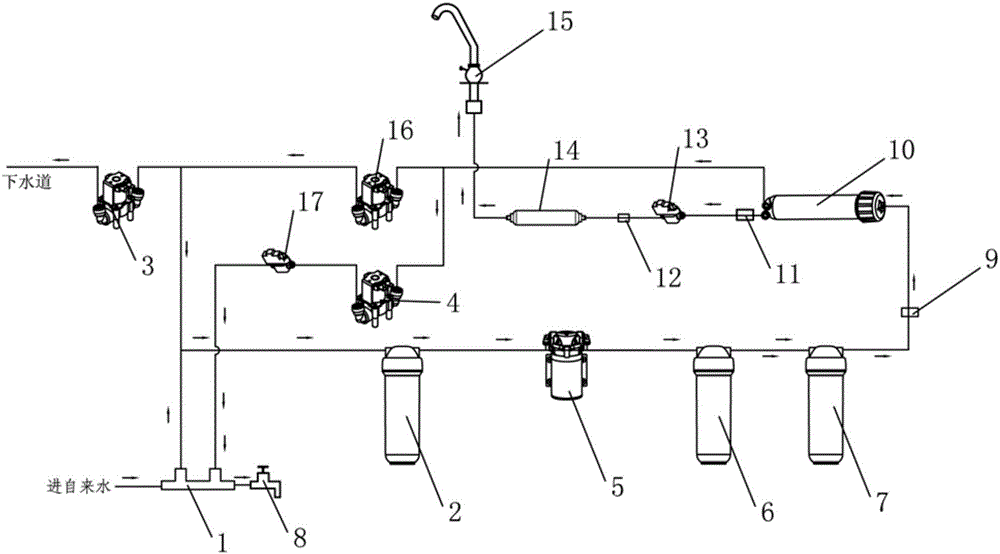

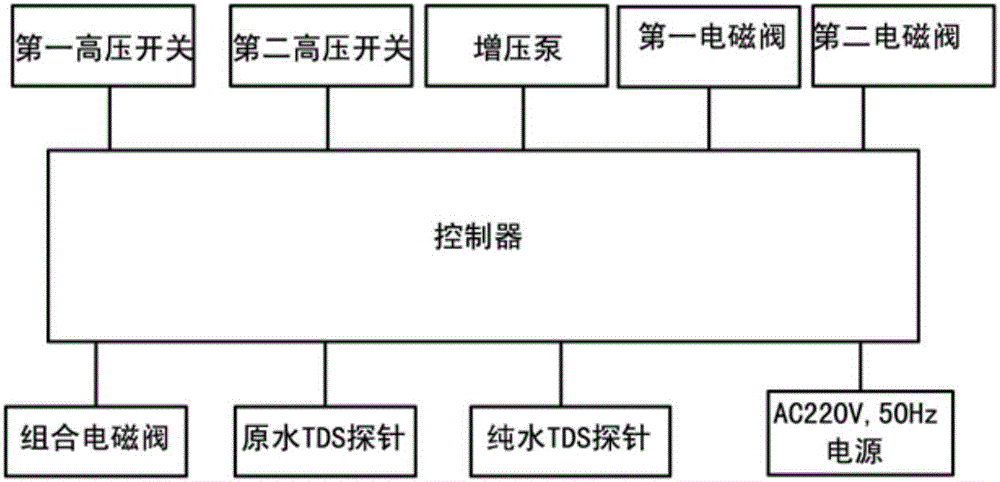

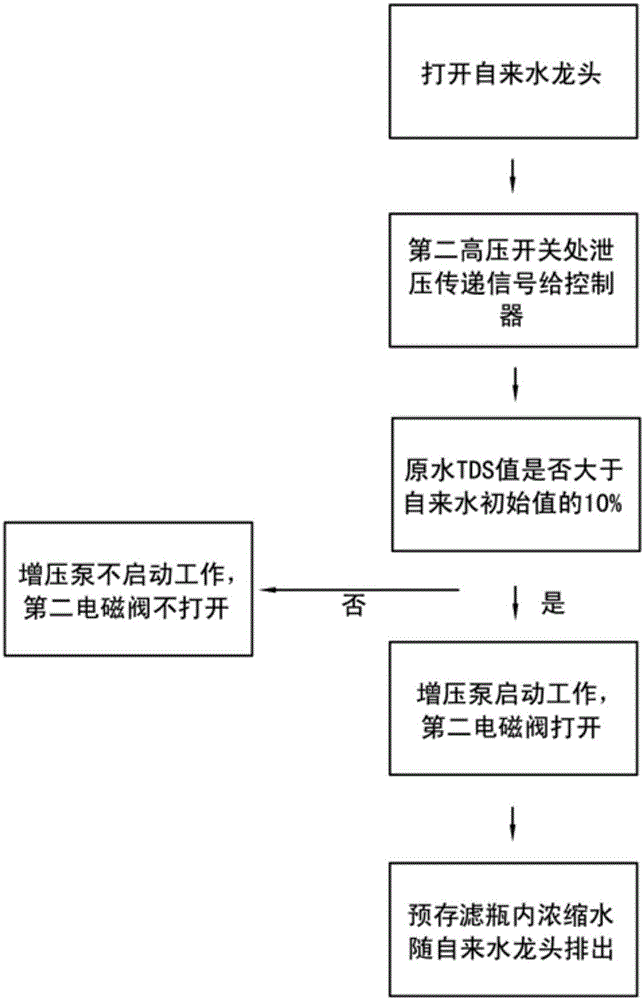

[0018] Such as figure 1 and figure 2 As shown, the tankless reverse osmosis water purifier system for improving water production rate according to the present invention mainly includes a controller, which is characterized in that: tap water passes through the PP cotton filter element filter bottle container 2 through the water inlet four-way 1 successively, The pressure pump 5, the first activated carbon filter element filter bottle container 6, and the second activated carbon filter element filter bottle container 7 communicate with the input end of the reverse osmosis membrane 10, between the second activated carbon filter element filter bottle container 7 and the front end of the reverse osmosis membrane 10 A raw water TDS probe 9 for raw water TDS detection is provided; the water outlet of the reverse osmosis membrane 10 is connected to the pure water faucet 15 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com