Integrated multiphase-flow treatment device for oil-containing sewage and sewage treatment method

A treatment device and technology for oily sewage, applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of silting in the filtration process, high energy consumption, long process, etc. To achieve the effect of avoiding silting, reducing the treatment process, and continuous and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand that the technical solutions of the present invention can be implemented, the present invention will be further described below in conjunction with specific examples, but the given examples are not intended to limit the present invention.

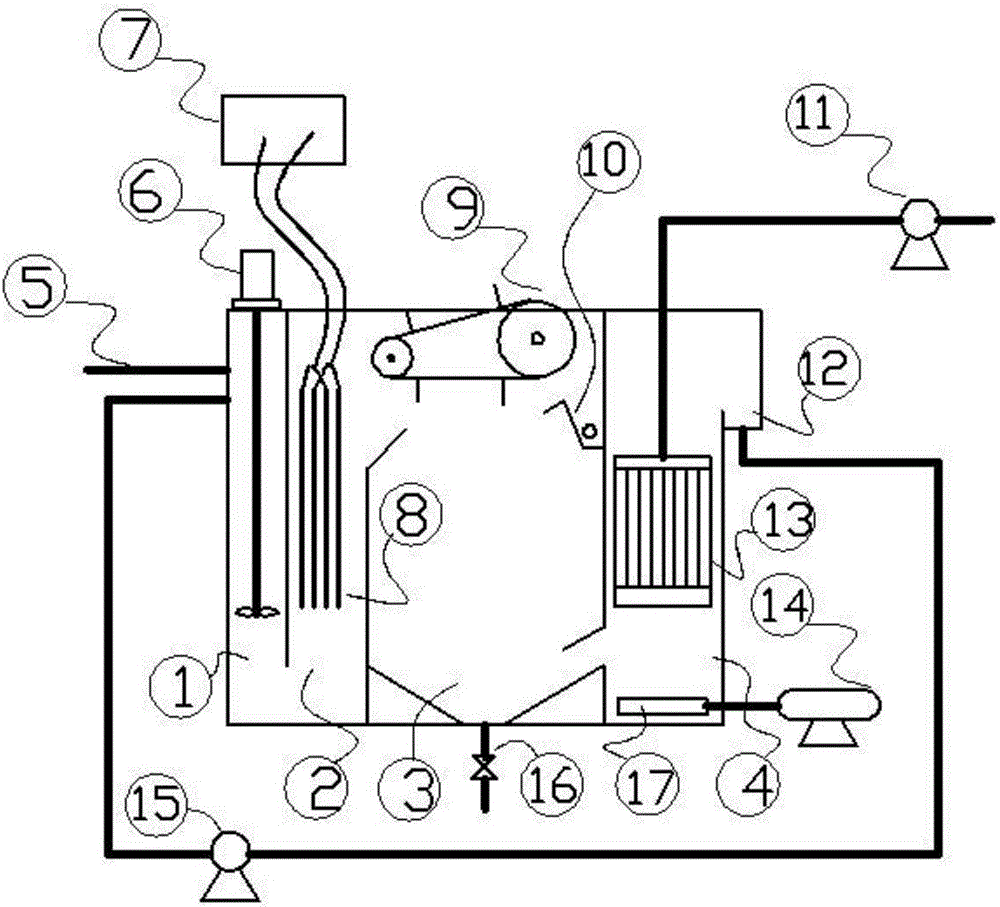

[0020] An integrated multiphase flow oily sewage treatment device, such as figure 1 As shown, it includes a complete pool body, which is divided into four functional chambers of different sizes by vertical partitions, namely mixing chamber 1, electrolytic air flotation chamber 2, sedimentation separation chamber 3 and membrane filtration chamber 4, Between the mixing chamber 1 and the electrolytic air flotation chamber 2 is a first partition, the bottom of the first partition is provided with a first bottom hole, between the sedimentation separation chamber 3 and the membrane filtration chamber 4 is a second partition, the second partition The bottom is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com