Optical glass and optical element

A technology of optical glass and optical components, applied in optical components, optics, instruments, etc., can solve the problems of unfavorable industrial production, easy devitrification of glass, high glass price, etc., and achieve good chemical stability, high transmittance, high The effect of high dispersion of refraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] In order to further understand the technical solutions of the present invention, preferred embodiments of the present invention will be described in conjunction with the following specific examples. However, it should be noted and understood that these examples are only for better illustrating the features and advantages of the present invention, and do not limit the claims of the present invention.

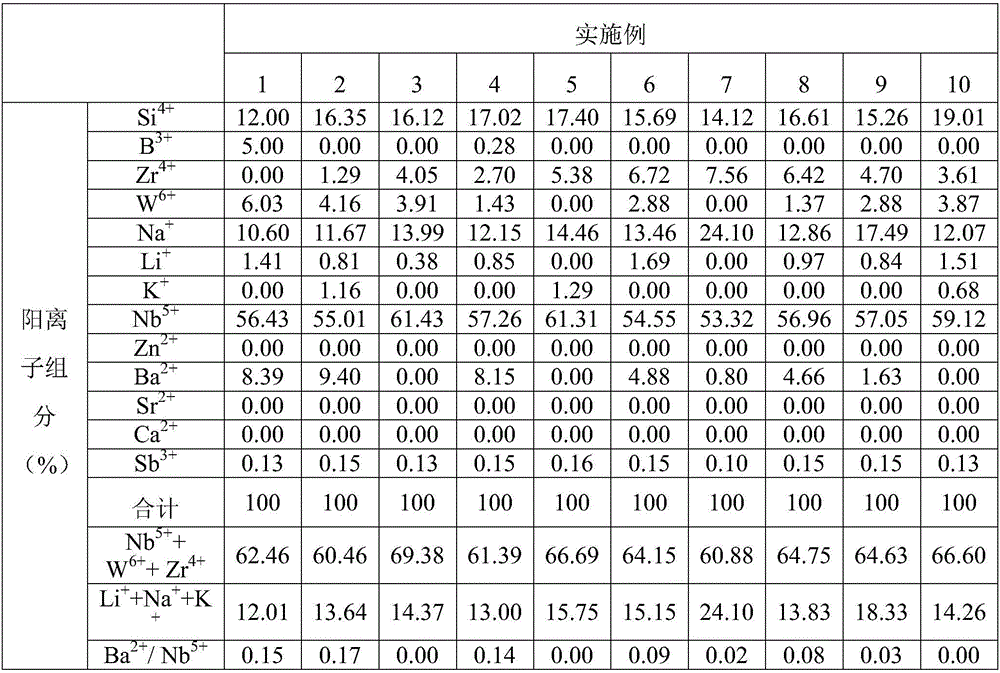

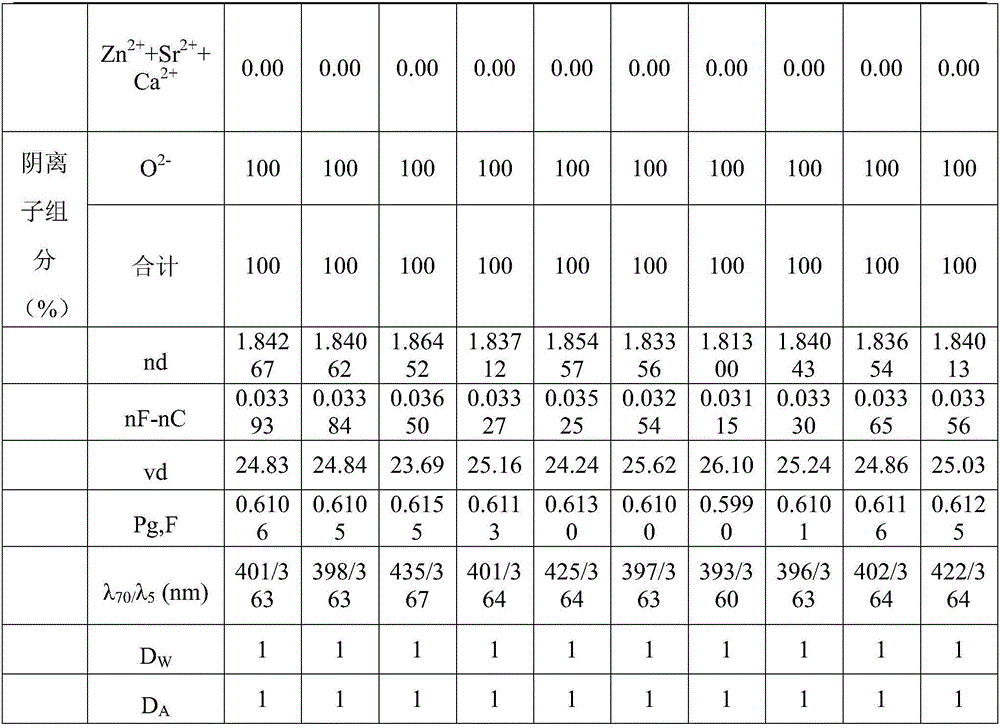

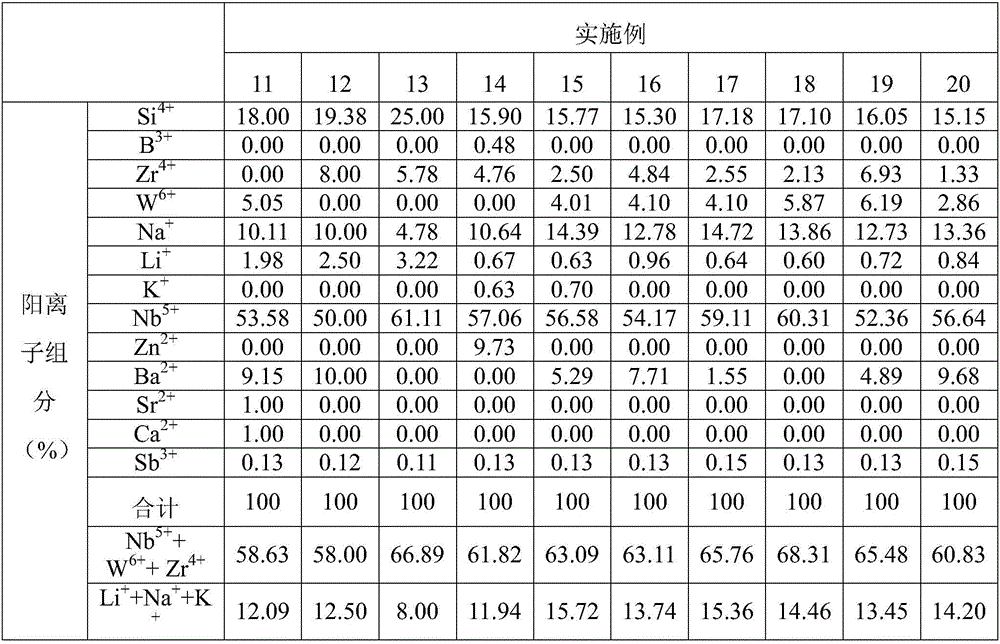

[0047] The optical glass components (expressed by weight percentage of cations) provided by Examples 1 to 30 of the present invention and their corresponding properties are shown in Tables 1 to 3. By weighing the oxides and carbonates corresponding to the various cations of the optical glass in the various examples in Tables 1 to 3 according to their ratios, mixing them thoroughly and adding them into the optical glass melting furnace, melting them at an appropriate process temperature, After clarification, stirring and homogenization, and cooling to a suitable temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com