Warm mix hard asphalt mixture and preparation method thereof

A technology of hard asphalt and mixture, applied in the direction of climate change adaptation, etc., can solve the problems of poor thermal stability and anti-aging performance of asphalt, environmental pollution, etc., to improve anti-aging performance, shorten reaction time, and improve adhesion. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

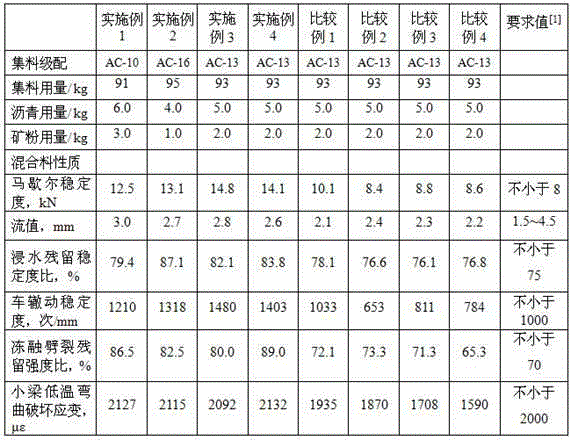

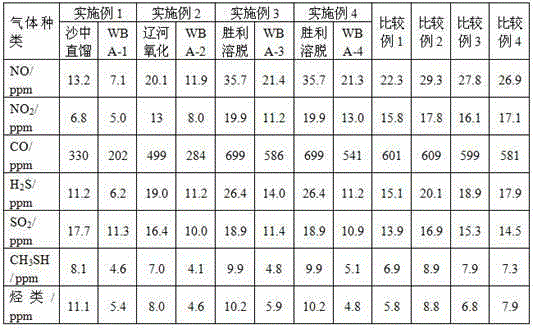

Examples

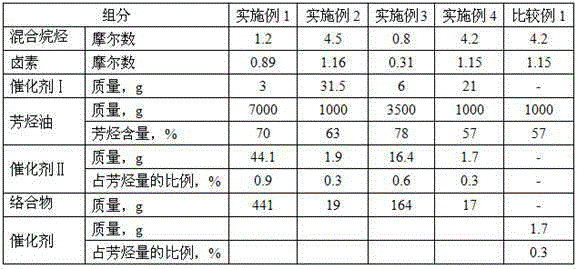

Embodiment 1

[0061] (1) Preparation of warm mix agent

[0062] Using Ni metal as a catalyst, the CO obtained after gasification of coal, and H 2 The synthesis reaction is carried out to obtain mixed alkanes in which alkanes with carbon numbers of 30 to 60 account for 90%.

[0063]①Weigh 1000g of the above-mentioned mixed alkanes, about 1.2mol, put them in a closed container, heat to 480°C, add 3g of catalyst anhydrous CuCl 2 , keep introducing 0.89 mol of chlorine at this temperature, and feed nitrogen to keep the pressure of the reaction vessel at 3MPa, and react for 30min to obtain the intermediate;

[0064] ②Weigh 7000g of the fourth-line extraction oil with 70% aromatics content, and add 441g of complex [Cu(NH 3 ) 4 〕SO 4 And 44.1g of catalyst Cu, packed in another airtight container and heated to 350 ° C, at this temperature constant temperature reaction for 180min, to obtain aromatic complex components;

[0065] ③Introduce the aromatic hydrocarbon complexing component into the a...

Embodiment 2

[0072] (1) Preparation of warm mix agent

[0073] Using Co metal as a catalyst, the CO obtained after gasification of coal, and H 2 The synthesis reaction is carried out to obtain mixed alkanes in which alkanes with carbon numbers of 30 to 130 account for 90%.

[0074] ① Weigh 3500g of the above-mentioned mixed alkanes, about 4.5mol, put them in a closed container, heat to 400°C, add 31.5g of catalyst anhydrous MnCl 2 , keep introducing 1.16mol of chlorine at this temperature, and feed nitrogen to keep the pressure of the reaction vessel at 5MPa, and react for 60min to obtain the intermediate;

[0075] ②Weigh 1000g of catalytic cracking oil slurry with an aromatics content of 63%, and add 19g of complex K to it 4 [Fe(CN) 6 ] and 1.9g of catalyst Fe were placed in another airtight container and heated to 270°C, and reacted at a constant temperature for 120min at this temperature to obtain aromatic hydrocarbon complex components;

[0076] ③Introduce the aromatic hydrocarbon ...

Embodiment 3

[0083] (1) Preparation of warm mix agent

[0084] Using Fe metal as a catalyst, CO obtained from gasification of coal, and H 2 The synthesis reaction is carried out to obtain mixed alkanes in which alkanes with carbon numbers of 70 to 90 account for 90%.

[0085] ①Weigh 1000g of the above-mentioned mixed alkanes, about 0.8mol, put them in a closed container, heat to 440°C, add 6g of catalyst anhydrous NiCl 2 , keep the temperature and introduce 0.31mol of fluorine, and feed nitrogen to keep the pressure of the reaction vessel at 4MPa, and react for 45min to obtain the intermediate;

[0086] ②Weigh 3500g of phenolic refined oil with aromatics content of 78%, and add 164g of complex [Ni(CO) 4 ] and 16.4g of catalyst Ni were placed in another airtight container and heated to 310°C, and reacted at a constant temperature for 160min at this temperature to obtain the aromatic hydrocarbon complexing component;

[0087] ③Introduce the aromatic hydrocarbon complexing component into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com