Soil conditioner used for rice and preparation method and application method thereof

A technology of soil conditioner and application method, which is applied in the field of rice soil conditioner and its preparation, which can solve the problems of rice production reduction, increased application without increasing production, soil environment deterioration, etc., to improve lodging resistance, increase yield and quality , Improve the effect of soil environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A preparation method for a soil conditioner for paddy rice, comprising the following steps:

[0046]1) Classification: the clinker is divided into two parts, which are respectively recorded as the first clinker and the second clinker; wherein, the particle size of the first clinker is greater than 100 mesh, and the particle size of the second clinker is less than 100 mesh. More than 100 mesh;

[0047] 2) Ball milling: placing the first clinker in a ball mill, and ball milling until the particle size is not greater than 100 mesh;

[0048] 3) Mixing: mix the ball-milled first clinker with the second clinker, and stir until uniform, to obtain the soil conditioner for rice.

[0049] As a preferred solution, the soil conditioner for rice is prepared according to the following steps:

[0050] 1) Ball milling: place the silicate soil conditioner clinker containing citrate-soluble silicon calcium magnesium and molybdenum in a ball mill, and ball mill to about 100 mesh;

[00...

Embodiment 1

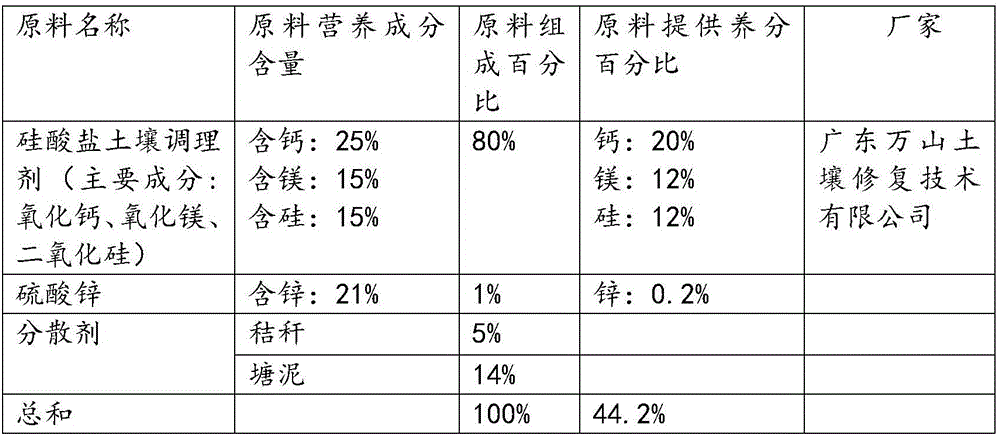

[0059] A soil conditioner for paddy rice, the effective nutrient components include 20% calcium, 12% magnesium, 12% silicon and 0.2% zinc. The raw material formula of this soil conditioner for paddy rice sees the following table 1 in detail:

[0060] The raw material formula table that is used for the soil conditioner of paddy rice of table 1 embodiment 1

[0061]

Embodiment 2

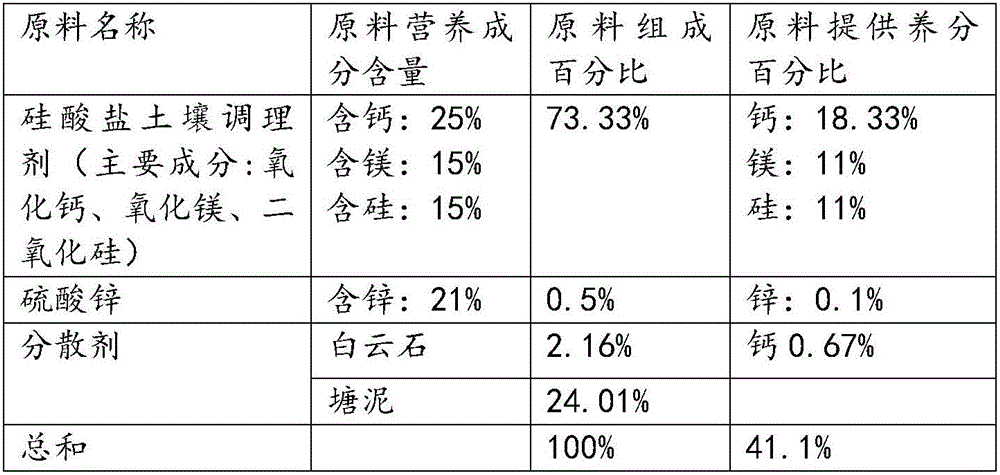

[0063] A soil conditioner for paddy rice, the effective nutrient components include 19% calcium, 11% magnesium, 11% silicon and 0.1% zinc. The raw material formula of this soil conditioner for paddy rice sees the following table 2 in detail:

[0064] The raw material formula table of the soil conditioner for paddy rice of table 2 embodiment 2

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com