Plastic gravure compound woven bag ink and preparation method thereof

A woven bag and gravure technology, which is applied in the field of plastic gravure composite woven bag ink and its preparation, can solve the problems of not being able to cast and compound, and achieve the effect of improving adhesion fastness and broad market development potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

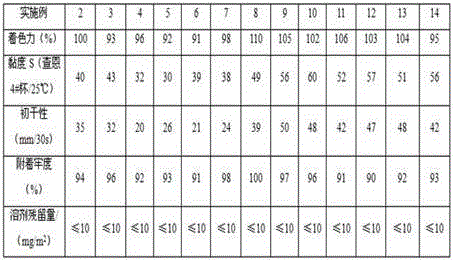

Examples

Embodiment 1

[0016] A plastic gravure composite woven bag ink, which is composed of the following raw materials in parts by weight: 25-30 parts of toluene, 2-4 parts of 40W resin, 3-6 parts of chlorinated polypropylene resin, 3-5 parts of 422 resin, pigments and fillers 15-25 parts, 32-50 parts of solvent.

[0017] It consists of the following raw materials in parts by weight: 25-30 parts of toluene, 2-3 parts of 40W resin, 4-5 parts of chlorinated polypropylene resin, 4-5 parts of 422 resin, 20-25 parts of pigment and filler, and 32-45 parts of solvent share.

[0018] Chlorinated polypropylene resin and 422 resin can improve the composite strength of ink to polypropylene.

[0019] The pigment and filler is any one of titanium dioxide, benzidine yellow, lisol red, carbon black and phthalocyanine blue.

[0020] The solvents were ethyl acetate and butyl acetate.

[0021] The preparation method is to add each raw material into a disperser and stir and disperse for 10-30 minutes, make it ev...

Embodiment 2

[0023] A plastic gravure composite woven bag ink is composed of the following raw materials in parts by weight: 25g of toluene, 2g of 40W resin, 3g of chlorinated polypropylene resin, 3g of 422 resin, 15g of titanium dioxide, 10g of ethyl acetate, and 22g of butyl acetate.

[0024] The preparation method is to add each raw material into the disperser and stir for 10 minutes to make it evenly mixed to form a pre-dispersed color paste, then pump the pre-dispersed color paste into the grinder for grinding, and grind repeatedly until the fineness of the material is within 10 microns , filtering, encapsulation.

Embodiment 3

[0026] A kind of plastic gravure composite woven bag ink, is made up of the raw material of following parts by weight: toluene 25.5g, 40W resin 2.2g, chlorinated polypropylene resin 3.3g, 422 resin 3.2g, titanium dioxide 16g, ethyl acetate 5g, acetic acid Butyl ester 30g.

[0027] The preparation method is to add each raw material into a disperser and stir for 12 minutes to make it evenly mixed to form a pre-dispersed color paste, then pump the pre-dispersed color paste into a grinder for grinding, and grind until the fineness of the material is within 10 microns , filtering, encapsulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com