Chlorinated polyether powder coating as well as preparation method and use method thereof

A technology of chlorinated polyether and powder coatings, applied in the direction of powder coatings, polyether coatings, coatings, etc., can solve the problems of insufficient adhesion of anti-friction coatings, improve toughness, improve compatibility, and improve The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

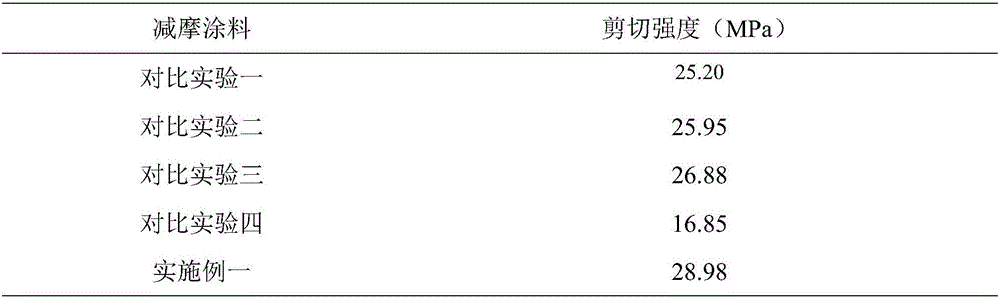

Examples

specific Embodiment approach 1

[0020] Specific embodiment 1: The chlorinated polyether powder coating in this embodiment consists of 90-100 parts by weight of chlorinated polyether, 0.1-0.2 parts of silane coupling agent, 1-10 parts of toughening agent and 1 part ~2 parts of antioxidants are prepared.

[0021] The beneficial effects of this embodiment are: the toughness of the powder coating is improved by adding the toughening agent; the compatibility between the chlorinated polyether and the toughening agent is improved by adding the silane coupling agent.

specific Embodiment approach 2

[0022] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the toughening agent is one or a mixture of high-density polyethylene and chlorinated polyethylene. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Specific embodiment three: the difference between this embodiment and one of specific embodiments one or two is: the antioxidant is triphenyl phosphite, 2,6-di-tert-butyl-4-methylphenol and One of 2,2'-methylenebis(4-methyl-6-tert-butylphenol) or a mixture of several of them. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap