A kind of composite gas hydrate accelerator and preparation method thereof

A technology of gas hydrate and accelerator, which is applied to promote the formation of other hydrates. , Composite accelerator and its preparation field, can solve the problems of low gas storage density, slow hydrate formation rate, etc., achieve the effect of less dosage, good promotion effect and simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

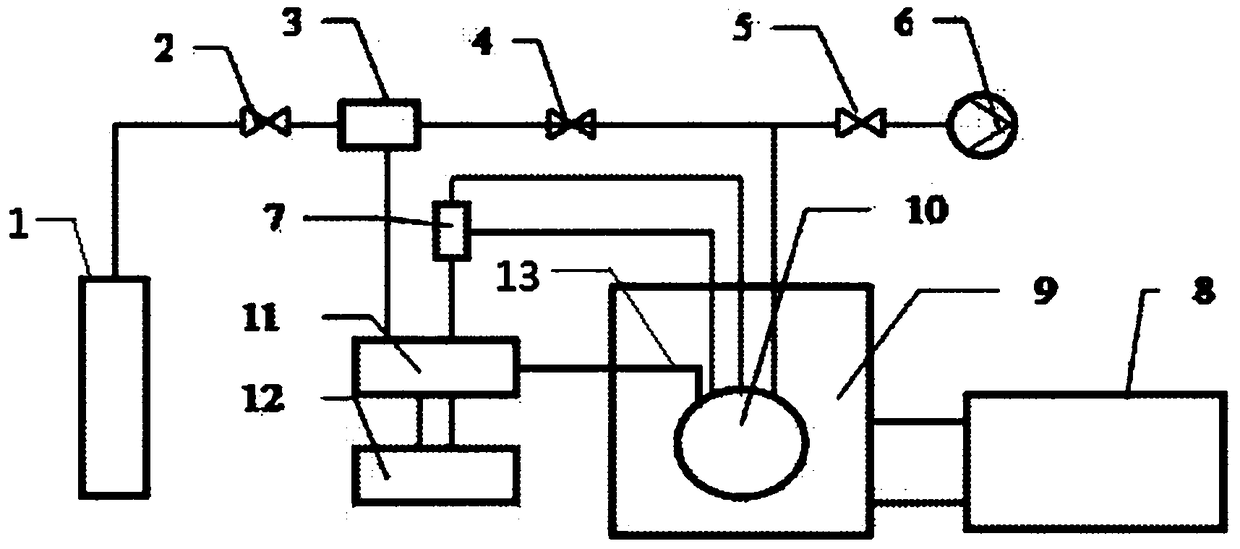

Method used

Image

Examples

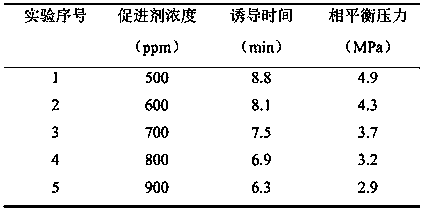

Embodiment 1

[0033] The selected composite accelerator consists of: 1% dodecyl hydroxypropyl phosphate betaine, 1% alkyl phosphate salt and 2.5% octadecylamidopropylamine oxide, and the concentration range after mixing is 500 ~900ppm accelerator aqueous solution, the test gas is methane with a purity of 99.99%, and the test temperature is 277.55K. The test is carried out with the above method, and the test data are shown in Table 1.

[0034] Table 1 Experimental results

[0035]

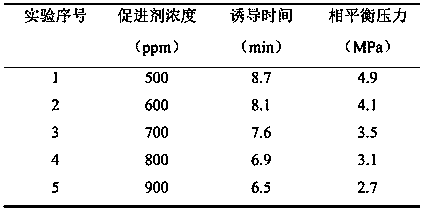

Embodiment 2

[0037] The selected composite accelerator consists of: 1.5% dodecyl hydroxypropyl phosphate betaine, 1.5% alkyl phosphate salt and 3% stearylamide propylamine oxide, and the concentration range after mixing is 500 ~900ppm accelerator aqueous solution, the test gas is methane with a purity of 99.99%, and the test temperature is 277.55K. The test is carried out by the above method, and the test data are shown in Table 2.

[0038] Table 2 Experimental results

[0039]

Embodiment 3

[0041] The selected composite accelerator consists of: 2% dodecyl hydroxypropyl phosphate betaine, 2.5% alkyl phosphate salt and 3.5% stearylamide propylamine oxide, and the concentration range after mixing is 500 ~900ppm accelerator aqueous solution, the test gas is methane with a purity of 99.99%, and the test temperature is 277.55K. The test is carried out with the above method, and the test data are shown in Table 3.

[0042] Table 3 Experimental results

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com