A local electroless nickel plating method for complex titanium alloy parts

A local chemical and titanium alloy technology, applied in the direction of liquid chemical plating, metal material coating process, plastic/resin/wax insulator, etc., can solve the impact of product quality, cannot effectively ensure smooth processing of products, and the shape of processed parts is complex and other problems, to achieve good protection effect, protection effect and method reliability improvement, and processing efficiency shortening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

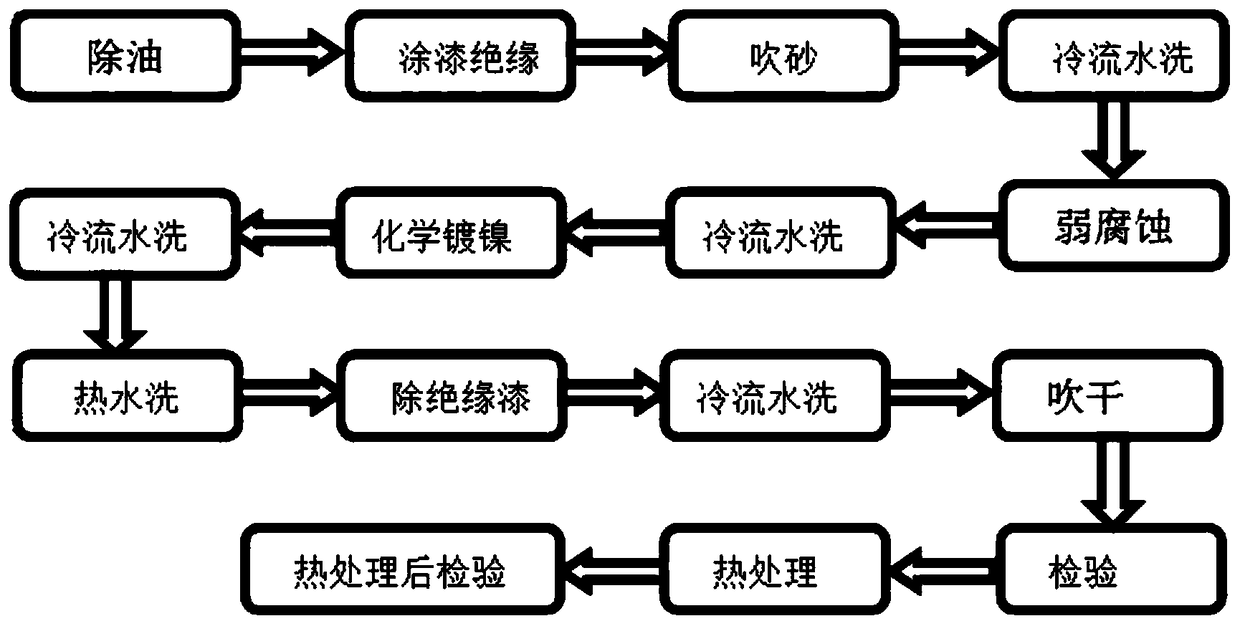

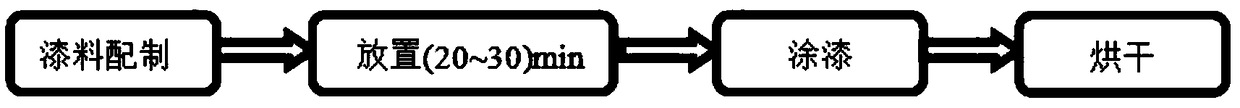

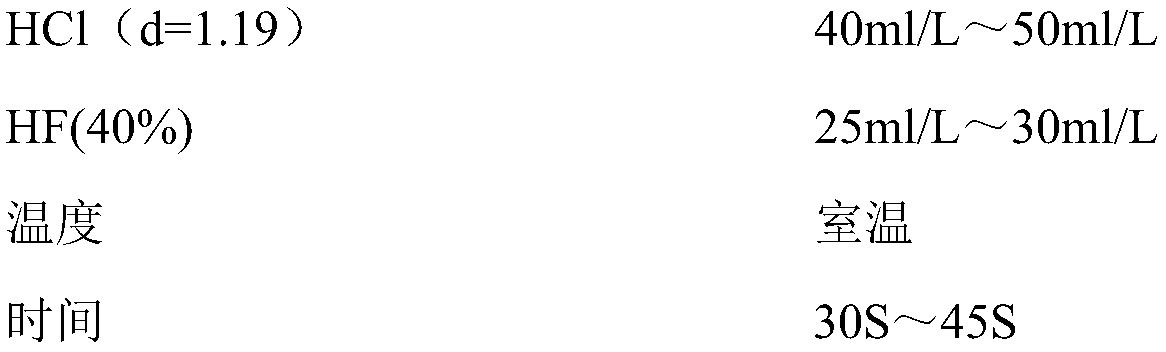

[0023] Such as figure 1 As shown, the electroless nickel plating of titanium alloy includes degreasing, paint insulation, sand blowing, cold water washing, weak corrosion, cold water washing, electroless nickel plating, cold water washing, hot water washing, insulating paint removal, cold water washing, blowing Drying, inspection, heat treatment and inspection after heat treatment. Among them, the titanium alloy electroless nickel plating process goes through three main processes: sand blowing, weak corrosion, and electroless nickel plating. (1) Sand blowing will affect the surface photometric state, so the non-nickel-plated surface of the part must be protected before sand-blasting, and the adjacent non-nickel-plated surface will also be blown, so the insulating protective film must be Can withstand sand blowing, and the film layer does not fall off. (2) The main component of weak corrosion is HCl (d=1.19) 40ml / L~50ml / L (the acid used in industry is not pure, d=1.19 means t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com