Vibration device for resonance crusher and resonance crusher

A vibrating device and crusher technology, which is applied to roads, buildings, road repairs, etc., can solve the problems of irregular beating of the vibration box, uneven force on the shock absorber, poor stability of the vibration device, etc., to achieve lifting and lowering. Quick response, superior maneuverability and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

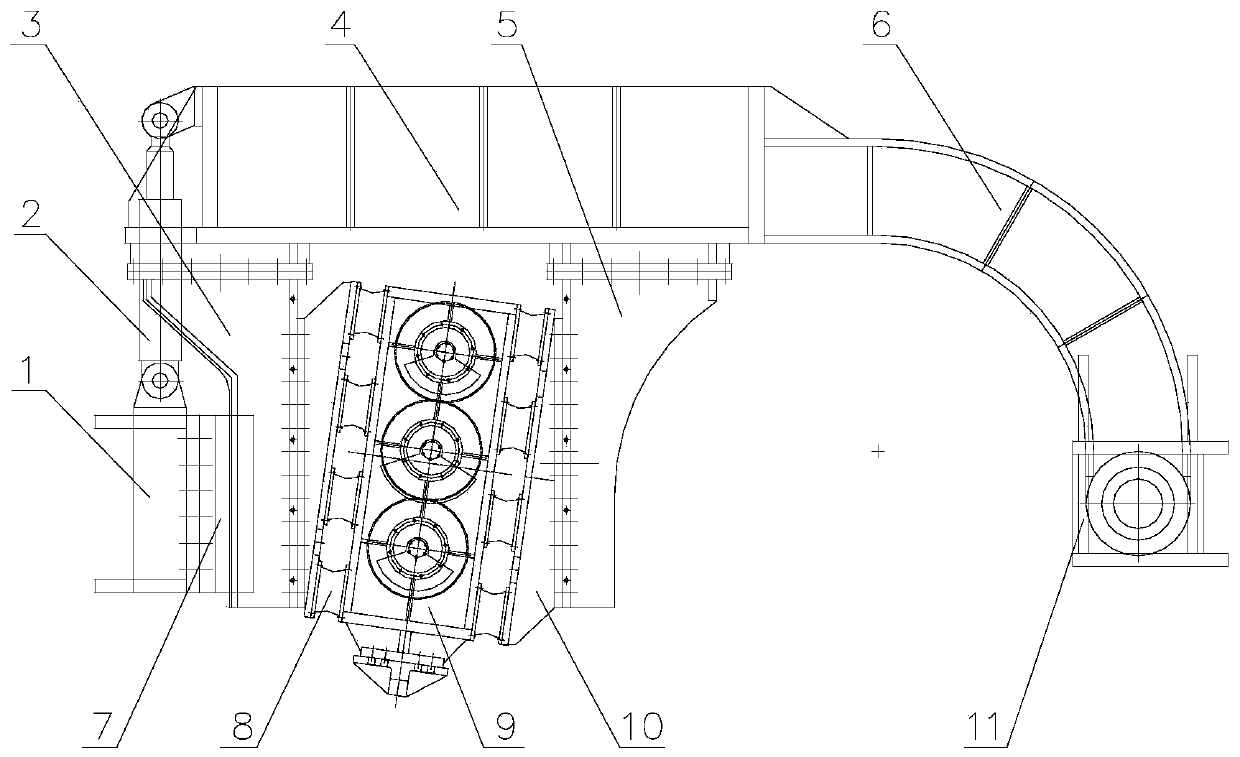

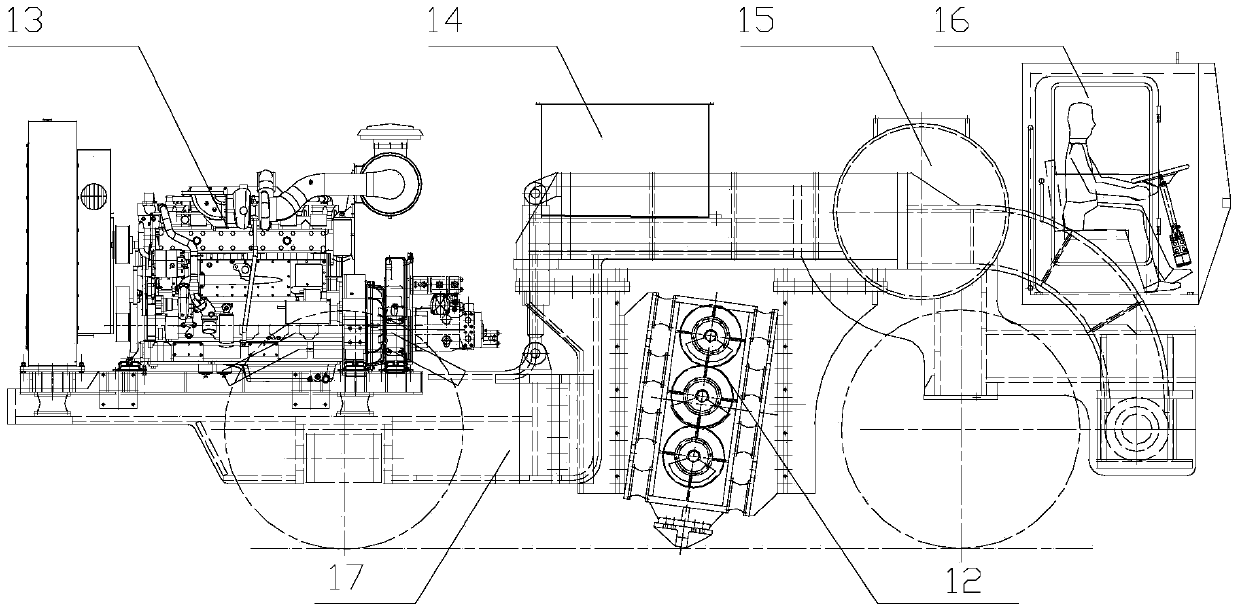

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

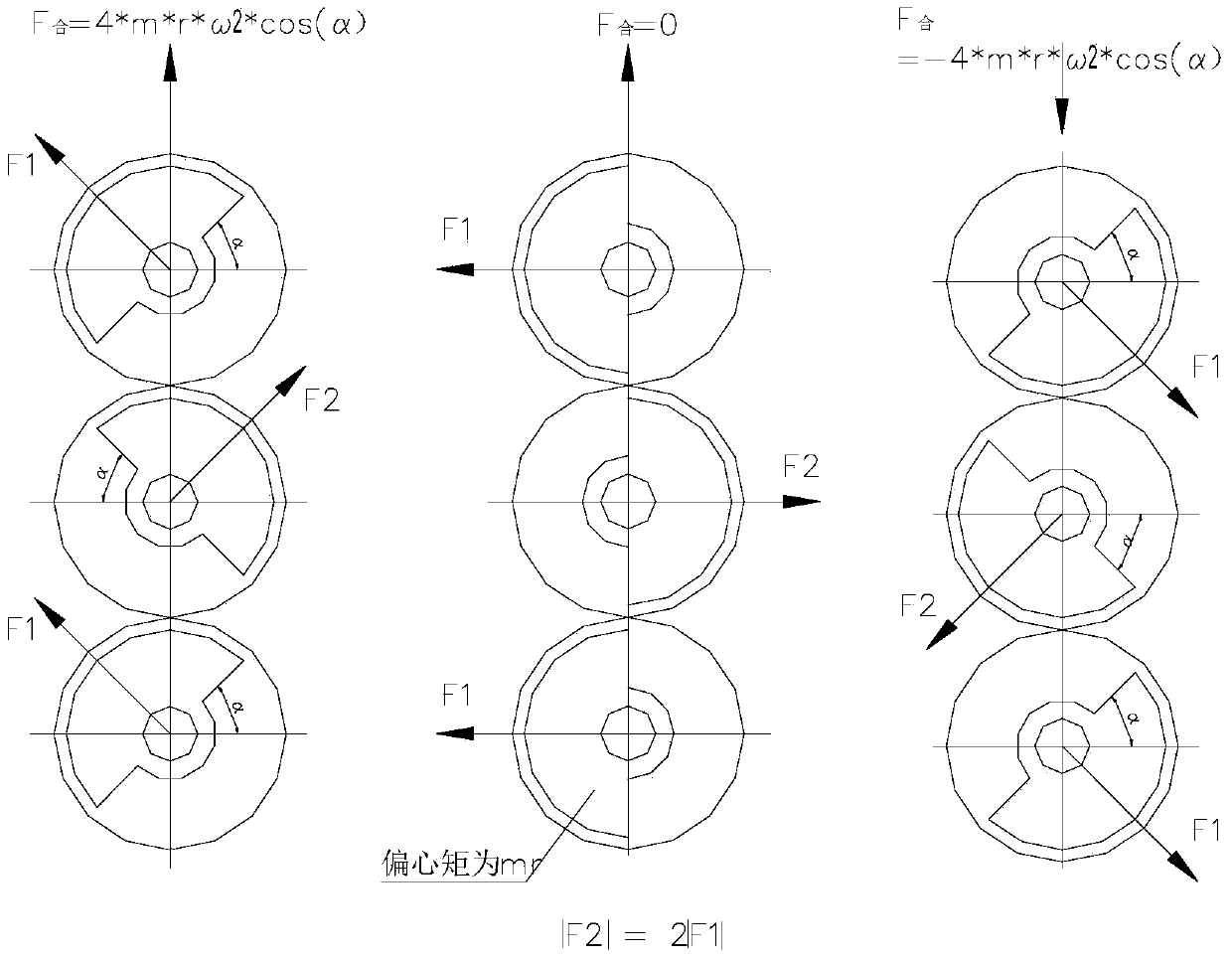

[0018] The embodiment of the present invention is used for the vibrating device of the resonant crusher, including the front hinge seat 11 and the rear hinge seat 1 respectively connected to the crusher body 17, and the upper part of the rear hinge seat 1 is connected with a jacking oil cylinder 2, The jacking cylinder 2 is connected to the front hinge seat 11 through the counterweight box 4 and the curved arm 6 connected in sequence; the bottom sides of the counterweight box 4 are respectively provided with a front stand 5 and a rear stand 3, and the One side of the rear stand 3 is movably connected in the guide seat 7 fixed on one side of the rear hinge seat 1, and a vibration unit is arranged between the rear stand 3 and the front stand 5, and the vibration unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com