Synchronous hydro-electric control cable force conversion system for suspender replacement and method for temporary bottom-carrying lifting device cable force conversion

A conversion system and cable force technology, which is applied in the field of cable force conversion of temporary hoisting devices, can solve the problems of no measuring device for jack displacement, influence on operation quality, and low construction efficiency, and achieve convenient standardized construction, high synchronization control accuracy, and manual The effect of low cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

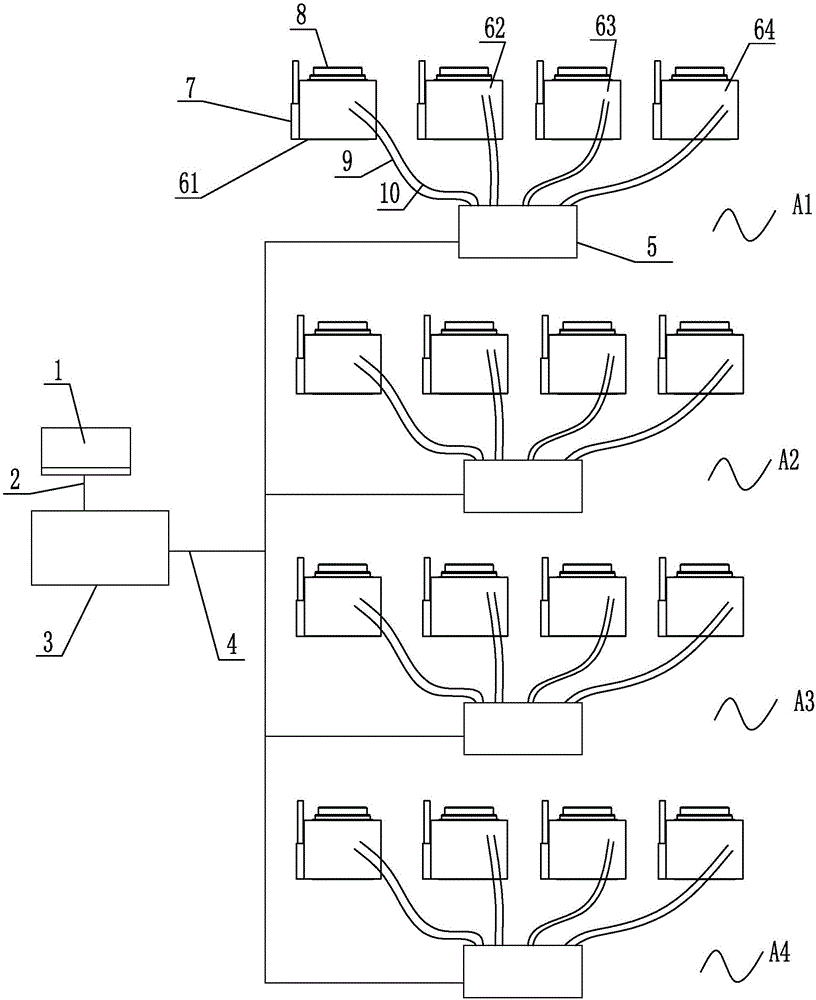

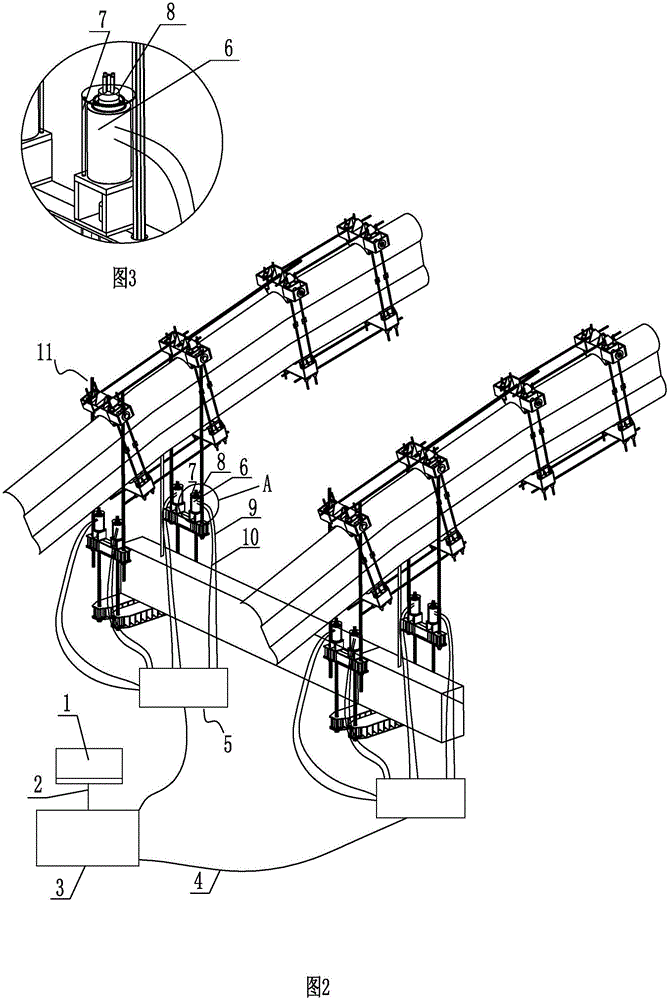

[0030] A synchronous hydroelectric control cable force conversion system for boom replacement, such as figure 1 As shown, the synchronous hydraulic-electric control cable force conversion system includes a centralized control computer 1, a main control box 3, and 4 sets of hydraulic pump station systems A1, A2, A3, and A4 for cable force conversion of temporary hoisting devices;

[0031] Each set of temporary hoisting device is configured with a set of hydraulic pump station system; each set of hydraulic pump station system used for cable-force conversion of temporary hoisting device includes a group of hydraulic pump station 5 and four jacks 61, 62, 63, 64, the hydraulic The pump station 5 independently controls the action, pressure and displacement of the four jacks; each jack is provided with a displacement sensor 7 and a pressure sensor 8; the displacement sensor 7 is installed on the side of each jack, and one end of the displacement sensor 7 (i.e. the lower end ) is fixe...

Embodiment 2

[0038] A method for converting the cable force of a temporary hoisting device, which uses the synchronous hydraulic-electric control cable force conversion system for boom replacement described in Embodiment 1 to realize the automatic hydraulic-electric control cable force loading and unloading of the temporary hoisting device to complete the cable force loading and unloading. The method of force conversion, that is: first use the system to use the centralized control computer 1 to control the switching valves of the hydraulic pump station 5 of each set of temporary hoisting devices through the PLC programming algorithm to synchronously control the pressure and displacement of each jack, and alternately complete the temporary lifting. The graded loading of the hanging device and the graded unloading of the old suspenders are used to realize the first conversion of the cable force, and then the old suspenders are removed and the new suspenders are installed. Finally, the system use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com