Rapid assembly type integrated house and building method thereof

An integrated housing and prefabricated technology, applied in building structures, buildings, building components, etc., can solve problems such as cumbersome manufacturing processes and complex structures, and achieve the effects of low technical level requirements, high connection strength, and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

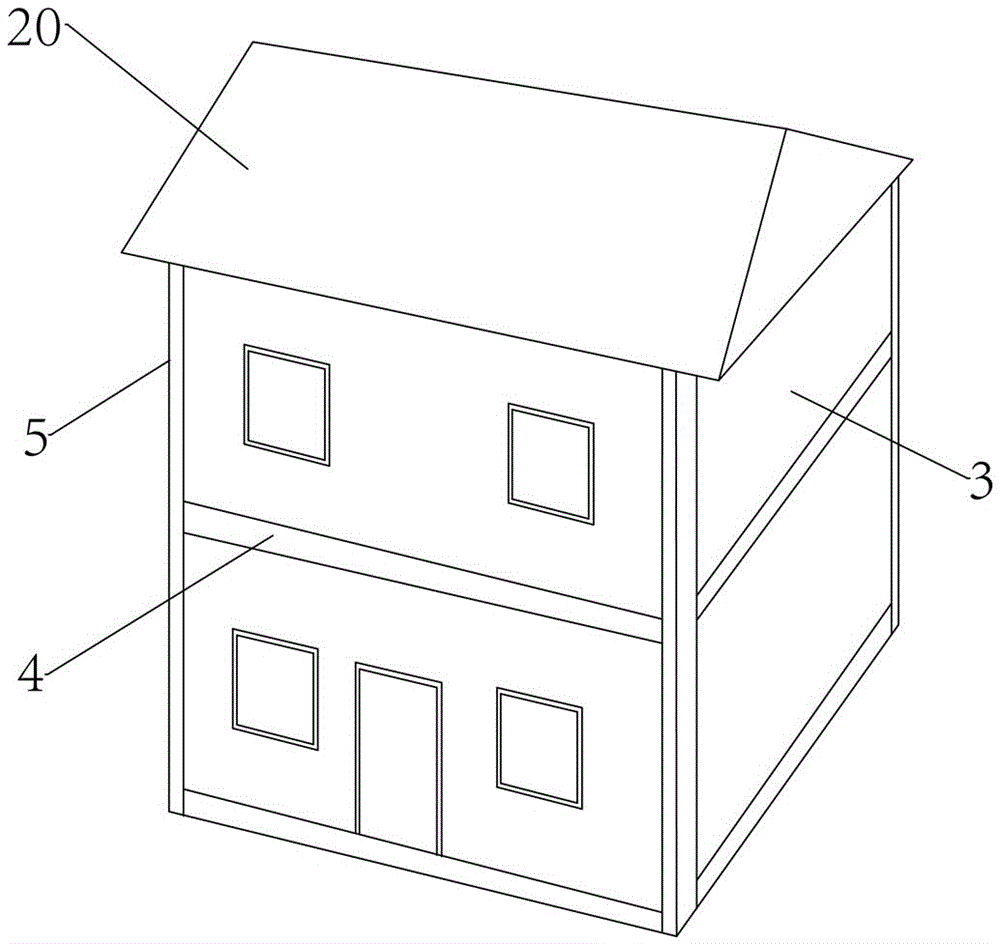

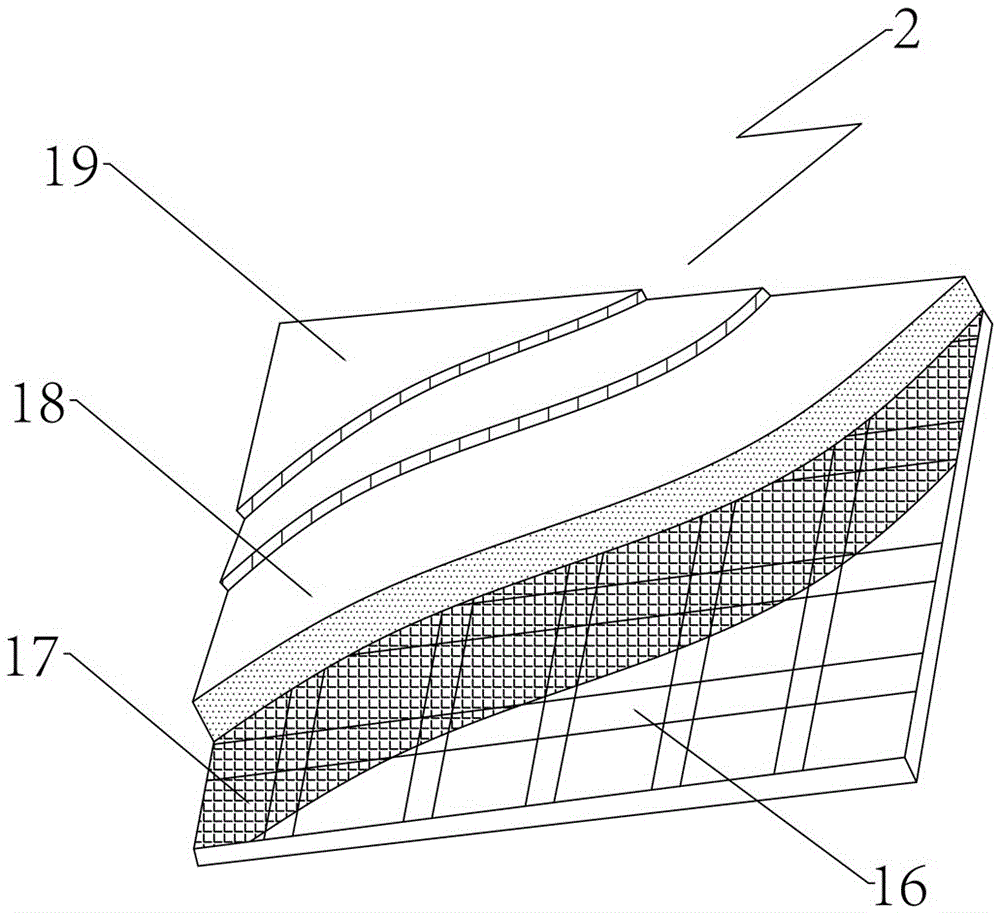

[0035] Such as figure 1 Shown, house of the present invention is mainly made up of parts such as main frame, floor slab 2, wallboard 3, roof 20.

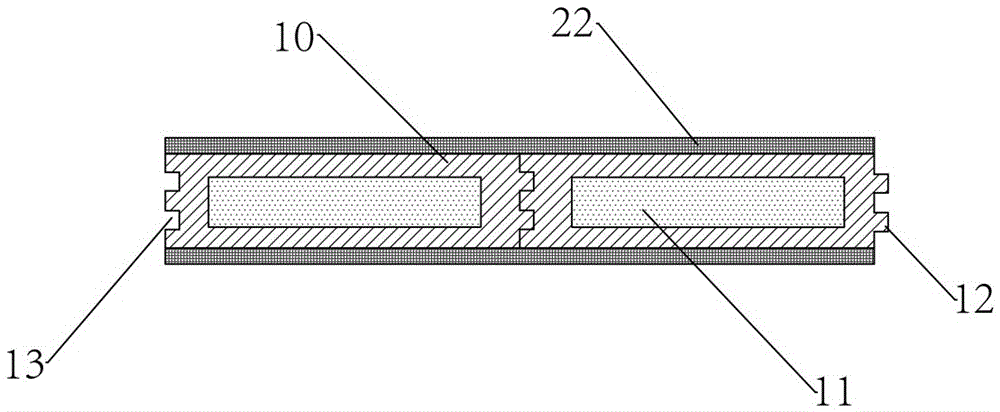

[0036] The main frame is a three-dimensional frame structure of a house assembled by welding and bolting a plurality of poles, and is used to carry other parts such as floor slabs 2 , wall panels 3 , and roof 20 . The poles used are made of architectural H-shaped steel, such as Figure 5 As shown in , the building H-shaped steel is a building-shaped steel with an H-shaped cross section, including two side plates 23 oppositely arranged and a connecting plate 24 connected in the middle of the two side plates 23. The connecting plate 24 connects the two side plates 23 The space between them is evenly divided into two parts to form two grooves for connecting with the side end surfaces of the wall panels 3 .

[0037] The main frame includes uprights 5 and several layers of horizontal rods 4 connected between the uprights 5 , the uprigh...

Embodiment 2

[0052] The building method of house of the present invention comprises the following steps:

[0053] a. Foundation: Make a strip foundation 1 on the ground, and embed the iron plate buried body in advance, then install the ground keel 21 on the upper surface of the finished foundation 1, and fix the ground keel 21 on the foundation 1 with expansion bolts on the surface. The foundation can also be made into an independent foundation.

[0054] b. Construction of the main frame: cut the building H-shaped steel into horizontal frame rods 4 and columns 5, and weld the bottom ends of the columns 5 to the pre-buried iron plate embedment, so that the vertical columns 5 on the same straight line The notches are opposite, and then the horizontal frame bar 4 is connected between the adjacent columns 5, so that the side plate 23 of the horizontal frame bar 4 remains parallel to the ground, and the end of the horizontal frame bar 4 is welded on the column 5; A second tenon 7 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com