Gas-containing coal permeation-increasing method adopting joint action of carbon dioxide detonation and acidification

A carbon dioxide and combined action technology, applied in chemical instruments and methods, gas discharge, mining fluids, etc., can solve problems such as inconsistent anti-reflection effects, unsatisfactory anti-reflection effects, and potential safety hazards in coal seams, so as to improve quality and Utilization value, corrosion inhibition and acidification ability, and the effect of improving gas drainage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

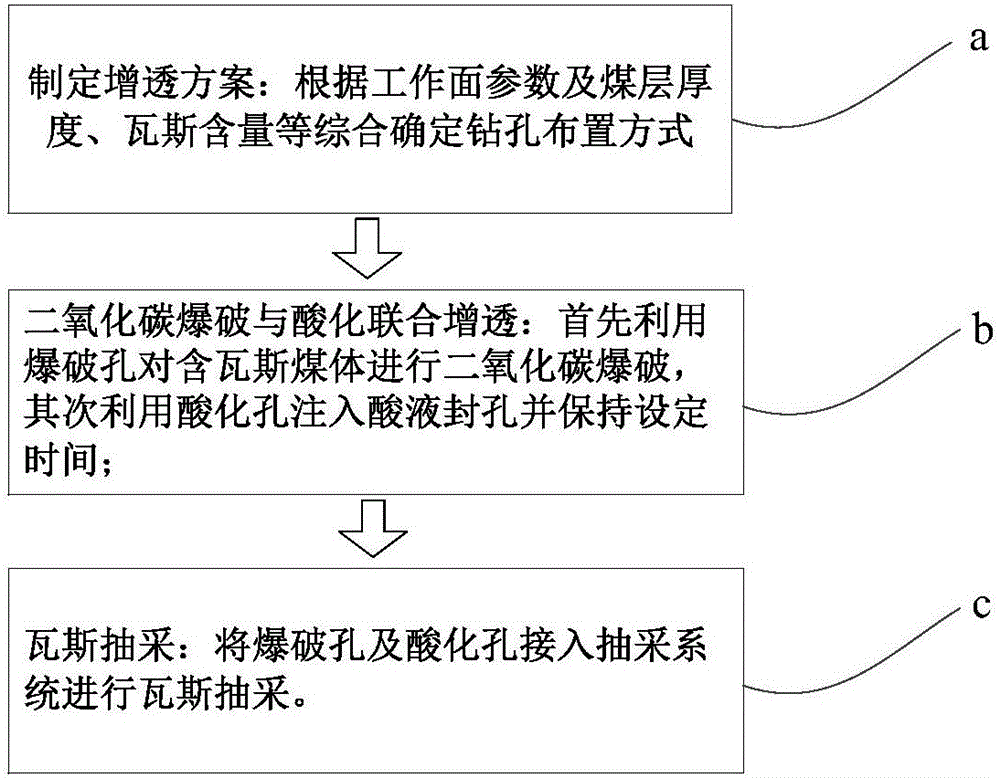

Method used

Image

Examples

Embodiment Construction

[0028] In order to fully demonstrate the features and advantages of the present invention, it will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0029] Research background: The 11103 working face of the C4 coal seam in a mine adopts the strike longwall mining method, in which the inclination length is 80m, the strike length is 600m, the thickness of the coal seam is 0.75-2.05m, and the average thickness is 1.40m. The coal seam structure is relatively simple and the horizon is relatively stable , Relatively reliable, and mineable in the area, it is a relatively stable coal seam. The average distance from the C5 coal seam at the top is 10.5m, and the average distance from the C3 coal seam at the bottom is 18.35m. The lithology of the roof is mudstone and sandy mudstone partially containing siltstone, and the lithology of the floor is mainly silty mudstone. The absolute gas pressure measured on site is up to 1.97MPa, the lowest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com