Self-cleaning system for offshore drilling module hydraulic oil system

A hydraulic oil and self-cleaning technology, which is applied in the field of self-cleaning systems, can solve problems such as high cleanliness requirements, impurity particles stuck, leakage of seals, etc., to shorten the flushing time, achieve recycling, and increase the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

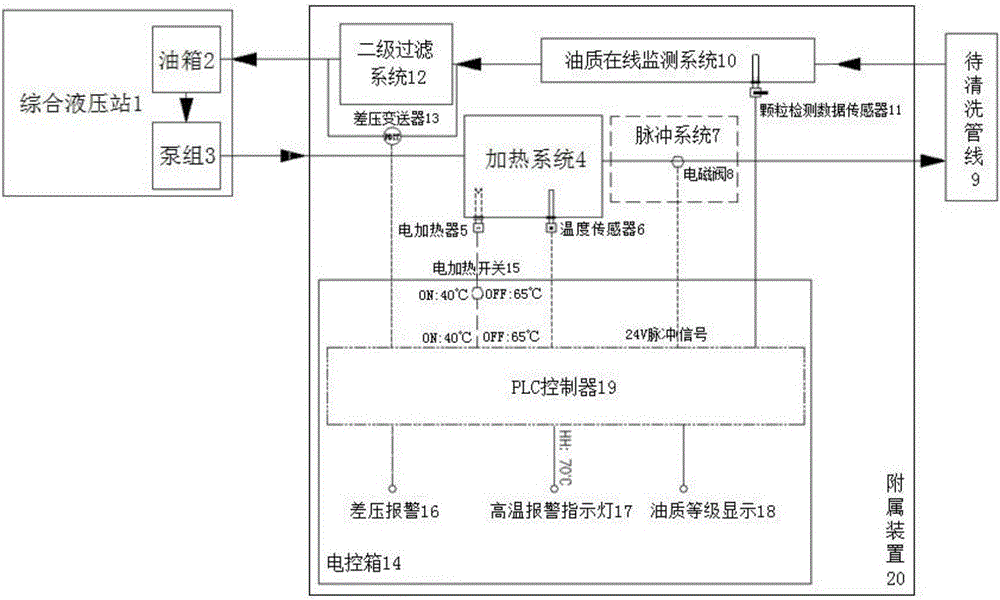

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] The present invention develops the self-cleaning accessory device 20 of the hydraulic system dedicated to the offshore drilling rig module, and utilizes the body pump group 3 and the oil tank 2 of the integrated hydraulic station 1 to realize the cleanliness of the hydraulic system pipeline and equipment during the construction of the drilling rig module and offshore maintenance to NAS level.

[0017] as attached figure 1 As shown, a self-cleaning system for the modular hydraulic oil system of an offshore drilling rig includes an oil tank 2 and a pump unit 3 connected to each other in a comprehensive hydraulic station 1, and the oil outlet of the pump unit 3 is connected to a heating system 4 and A pulse system 7, the heating system 4 is provided with an electric heater 5 and a temperature sensor 6 connected to the electric control box 14, and the pulse system 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com