High-heat-resistance sealed cabin pipeline cabin penetration flange and machining method

A sealed cabin, high thermal resistance technology, applied in the direction of pipes, pipes/pipe joints/fittings, mechanical equipment, etc. With problems such as high thermal resistance characteristics, to achieve the effect of reducing the response and slowing down the transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

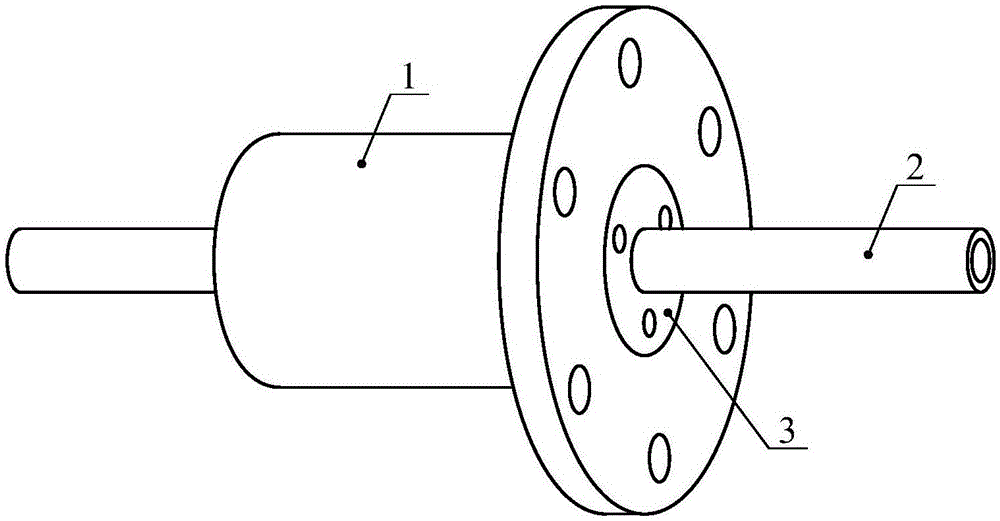

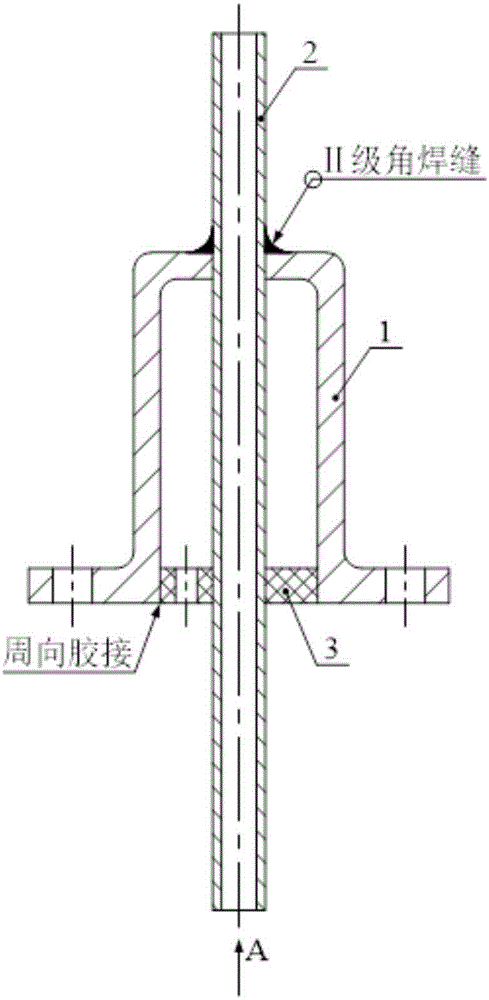

[0020] Embodiment 1, refer to the accompanying drawings: a high thermal resistance airtight cabin pipeline piercing flange, which includes: a cup-shaped flange seat 1, a conduit 2 and a support gasket 3;

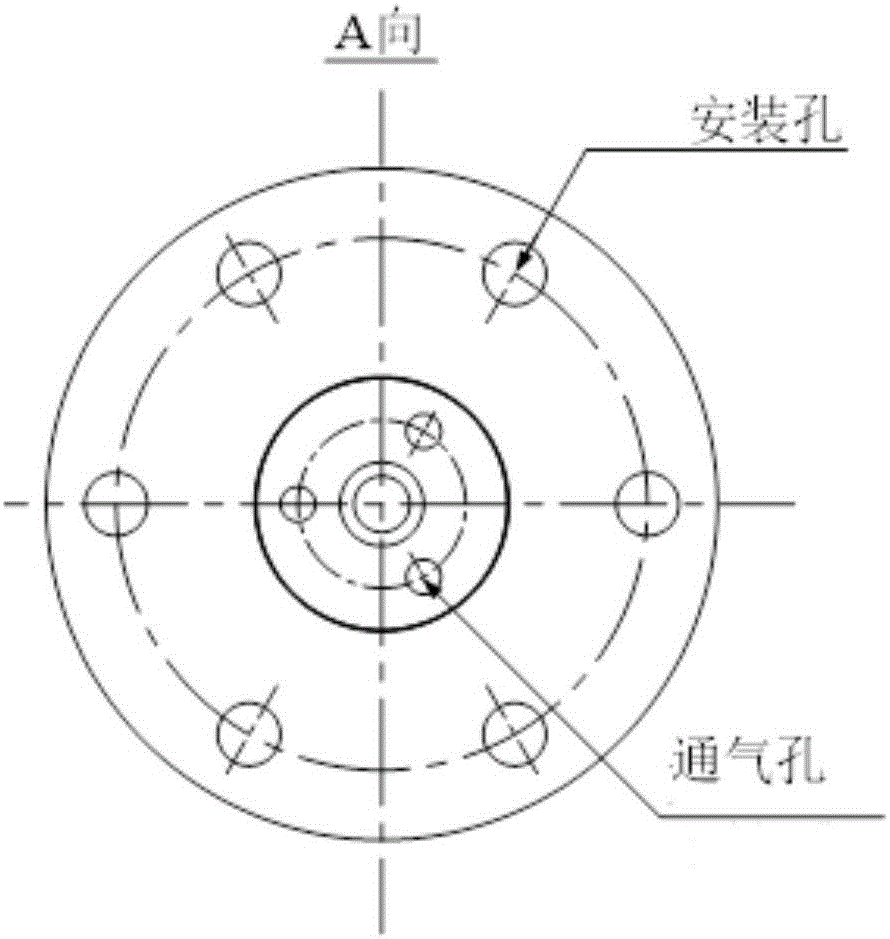

[0021] The cup-shaped flange seat 1 includes: a cylindrical cup body and a flange seat formed by the shoulder of the cup body opening; the outer diameter of the cup body is 1 / 2 of the diameter of the flange seat, and the height of the cup body is equal to that of the flange seat. diameter; the center of the flange seat is provided with a through hole, and the open end of the cup body is welded on the end face of the flange seat; the end face of the flange seat is also provided with mounting holes for connecting with the cabin structure in the circumferential direction;

[0022] One end of the conduit 2 passes through the bottom of the cup body in the cup-shaped flange seat 1 and is fixed by welding, the other end passes through the central through hole of the flange seat, and...

Embodiment 2

[0025] Embodiment 2, the processing method of the pipeline piercing flange of the sealed cabin with high thermal resistance, comprises the following steps:

[0026] A. The outer diameter of the cup body of the cup-shaped flange seat 1 is designed to be 1 / 2 of the diameter of the flange, and the height of the cup body is equal to the diameter of the flange, or the cup body diameter and The height dimension of the cup body is designed; there are 4 to 6 installation holes evenly distributed on the circumference of the flange plate, which are used for sealing connection with the cabin structure; Before processing, it is necessary to conduct flaw detection on the blank. It is required that the selected blank has no inclusions, no pores, no cracks and indentations on the surface, and it is formed by cutting and milling. Feed speed, in order to prevent secondary damage such as extrusion and scratches on the flange seat;

[0027] B. Cut off the conduit 2 of the spacecraft piping syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com