Novel superheater hoisting installation

A hoisting device and superheater technology, which is used in steam superheating, boiler support/positioning device, transportation and packaging, etc., can solve the problems of high hoisting cost, large fluctuation of moisture content and calorific value, and installation of hoisting points, etc. To achieve the effect of ample space for maintenance and pipe replacement, reduced pipe replacement workload, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

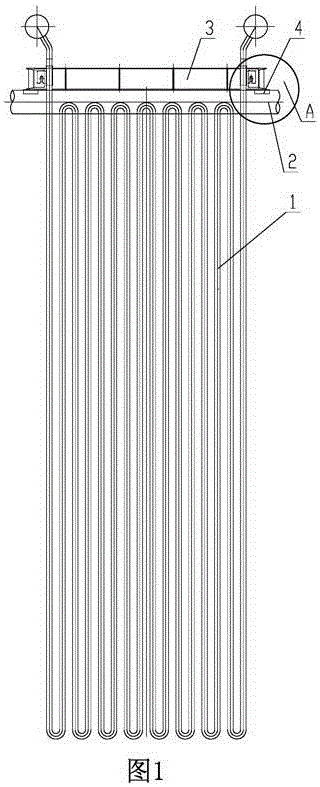

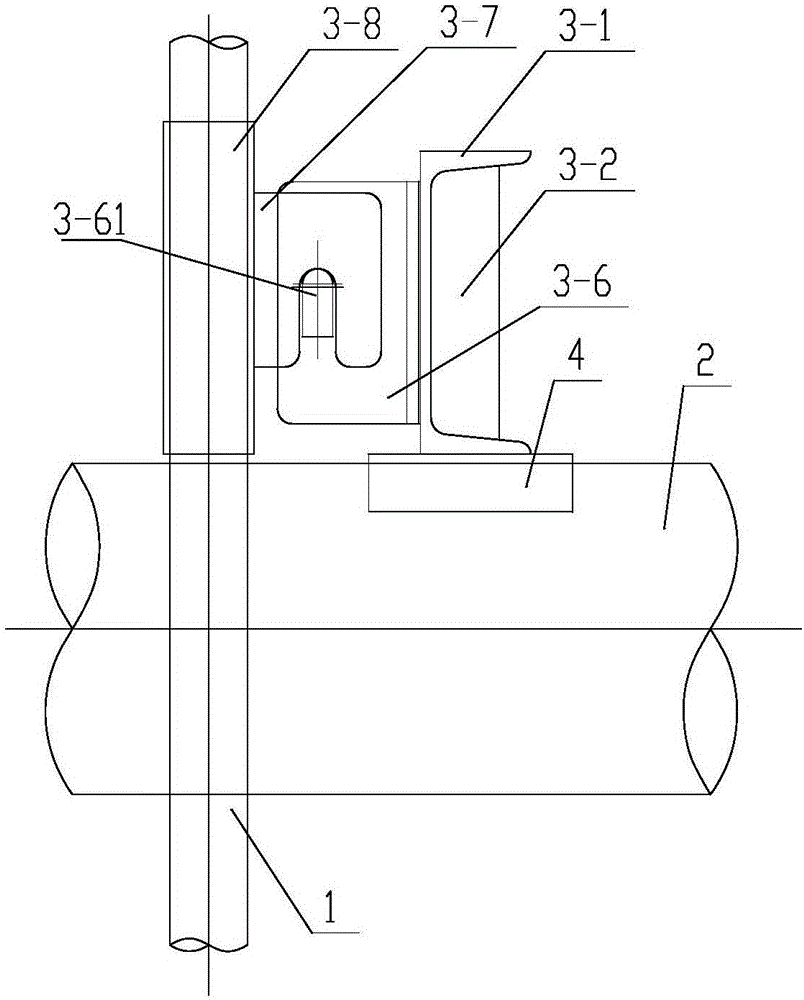

[0022] figure 1 The new superheater hoisting device shown includes a fixed frame 3 fixed (welded) on the horizontal flue header 2 by a positioning steel plate 4 and a number of hangers that detachably hook and connect the superheater 1 to the fixed frame. Hanging components; so that the superheater is hoisted on the horizontal flue header by hanging.

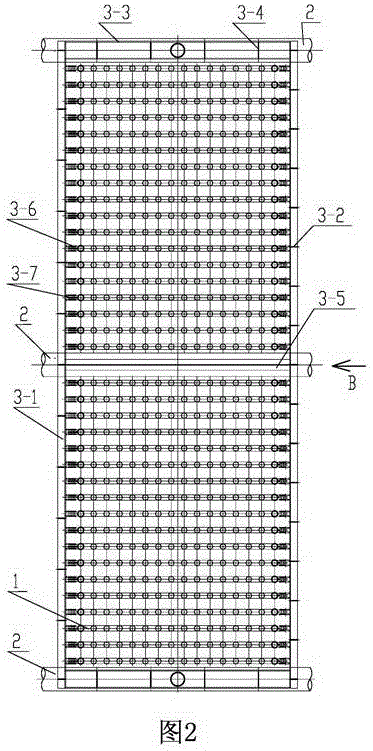

[0023] The fixed frame includes two channel steels 3-1 parallel to each other and two steel trusses parallel to each other, forming a horizontally arranged rectangular frame (welded at the junction of the channel steel and the steel trusses). The opening of the channel steel faces the outside of the fixed frame and the symmetrical center line of the opening is parallel to the horizontal plane, and several vertically arranged ribs 3-2 are welded and fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com