Evaporator for ultrathin type air conditioner

An ultra-thin, evaporator technology, used in evaporators/condensers, heat sinks, tubular elements, etc., can solve problems such as layer height compression, reduced activity space, etc., to achieve stable cooling and heating, small overall thickness, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

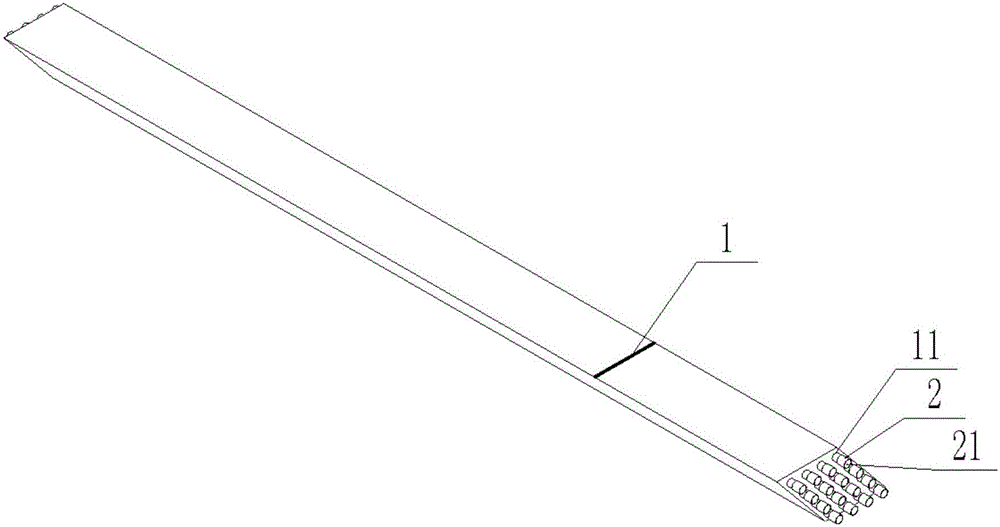

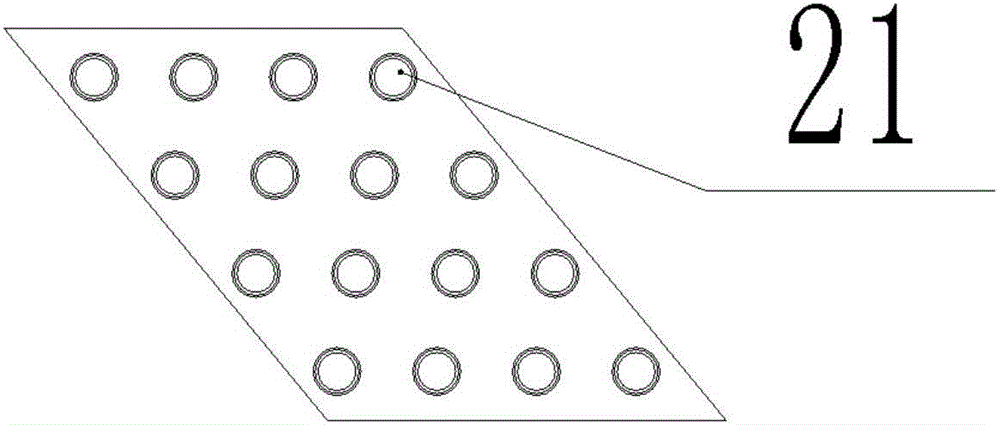

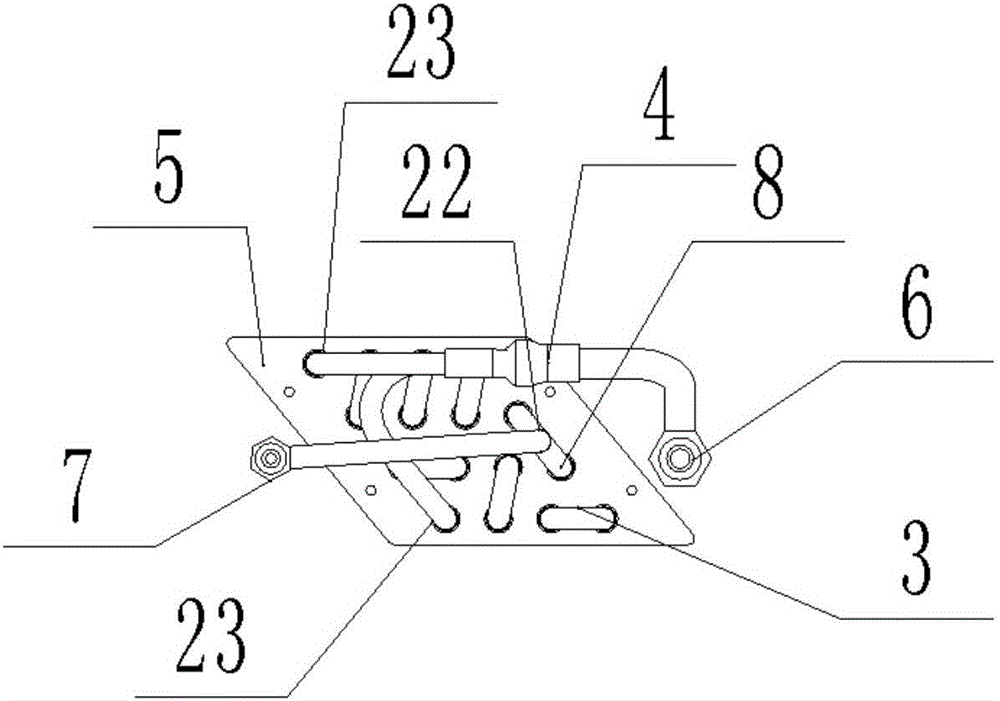

[0020] Please refer to the attached image 3 As shown, preferably, the pitch of the hypotenuse of the fin 1 is 50.800mm, the angle between the hypotenuse and the horizontal plane is 50.1°, and the height is 64.740mm, and the fin 1 is connected in series one by one, through The through holes 11 are arranged side by side in the body of the long U tube 2. The thickness of the fins 1 is 0.105 mm, the spacing between the fins 1 is 1.400 mm, and the total number is 607. The through holes 11 are 4 rows. There are 4 in each row. The said long U tubes 2 are in 4 rows, 2 in each row, and the nozzles 21 are connected by small elbows 3, small elbows 8 with openings or Y-shaped three-way pipes 4.

[0021] In this embodiment, the long U tubes 2 are preferably connected in the following order:

[0022] The first orifice 2101 in the first row and the first orifice 2113 in the fourth row are connected with the Y-shaped three-way pipe 4 to form an outlet pipe 23. The outlet pipe 24 is connected to t...

Embodiment 2

[0024] Figure 4 This is a schematic cross-sectional view of the fin set of Embodiment 2. Preferably, the difference from Embodiment 1 is that the pitch of the oblique side of the fin 1 of Embodiment 2 is 38.100mm, and the number of rows of through holes 11 is 3 rows. The described long U tube 2 has 3 rows, 2 in each row.

[0025] Since the specific connection method is not limited, preferably, one of the nozzles 21 is connected to the air outlet assembly 6 of the air conditioner, or no less than one, and the nozzles 21 belonging to the U pipe 2 of different length pass through the small elbow 8 with opening. It is connected to the air outlet assembly 6 of the air conditioner, one or more of the nozzles 21 are connected to the air inlet assembly 7 of the air conditioner, and the remaining nozzles 21 are connected by a small elbow 3.

Embodiment 3

[0027] Figure 5 It is a schematic cross-sectional view of the fin set of Embodiment 3. Preferably, the difference from Embodiments 1 and 2 is that the pitch of the hypotenuse of the fin 1 of Embodiment 2 is 25.400 mm, and the number of rows of through holes 11 is 2. The corresponding connection modes are not completely the same. The long U pipe 2 has two rows, with two in each row.

[0028] Since the specific connection method is not limited, preferably, one of the nozzles 21 is connected to the air outlet assembly 6 of the air conditioner, or no less than one, and the nozzles 21 belonging to the U-tube 2 of different length pass through the small elbow 8 with opening. It is connected to the air outlet assembly 6 of the air conditioner, one or more of the nozzles 21 are connected to the air inlet assembly 7 of the air conditioner, and the remaining nozzles 21 are connected with a small elbow 3.

[0029] The embodiment of the present invention is not limited to the above three exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com