Hydraulic damper sealing double-medium detection apparatus and detection method thereof

A hydraulic shock absorber and detection device technology, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the increase and deceleration rate of the fluid, can solve the problems that the accuracy of the detection results cannot be guaranteed, and shorten the detection time , Eliminate loading waiting time, reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

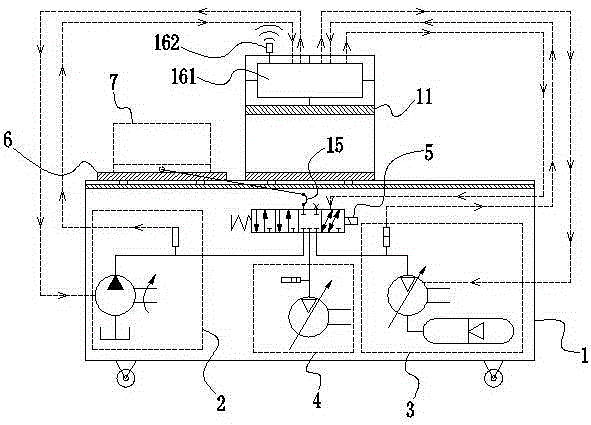

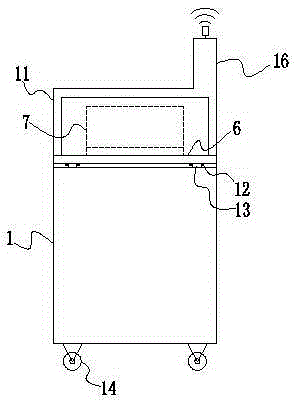

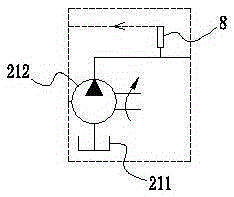

[0043] Embodiment 1: as figure 1 and figure 2 As shown, a hydraulic shock absorber tightness dual-medium detection device includes a device main body 1, and the hydraulic shock absorber tightness double-medium detection device also includes a working module arranged inside the device main body 1, and the working module includes Hydraulic detection unit 2, air pressure detection unit 3, vacuum unit 4 and reversing valve 5; a detection operation platform 6 is also arranged on the top of the device main body 1, and a hydraulic shock absorber 7 is fixedly placed on the detection operation platform 6 , the working module is connected with the inner cavity of the hydraulic shock absorber 7 through the reversing valve 5, and the hydraulic detection unit 2, the vacuuming unit 4 or the air pressure detection unit 3 can be controlled respectively by the action of the reversing valve 5 to work on the hydraulic shock absorber 7 Therefore, the sealing performance of the hydraulic shock a...

Embodiment 2

[0061] Embodiment 2: as Figure 6 As shown, compared with Embodiment 1, the difference is that: the detection operation platform 6 is provided with two, which are respectively detection operation platform one 611 and detection operation platform two 612; detection operation platform one 611 and detection operation platform Two 612 are divided into two positions located on both sides of the safety shield 11. The reversing valve 5 can adopt a four-position five-way reversing valve, and the hydraulic detection unit 2, the air pressure detection unit 3 and the vacuum unit 4 are respectively connected with three oil inlet and outlet ports in the reversing valve 5. One reversing oil port of the reversing oil port is connected with the inner chamber of the hydraulic shock absorber 7 on the detection operation platform 1 611 through the connecting pipe 15, and the other reversing oil port in the reversing valve 5 is connected with the detection operation platform through the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com