A membrane clamping device that can be used for double-membrane constant-pressure rupture and single-membrane impact rupture

A membrane-breaking and single-membrane technology, which is applied in measuring devices, testing of machines/structural components, instruments, etc., can solve the problems of cumbersome wind tunnel operation, reduced wind tunnel operation efficiency, airflow impact, etc., to improve wind tunnel operation Efficiency, saving wind tunnel manufacturing cost, and reducing the effect of airflow impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

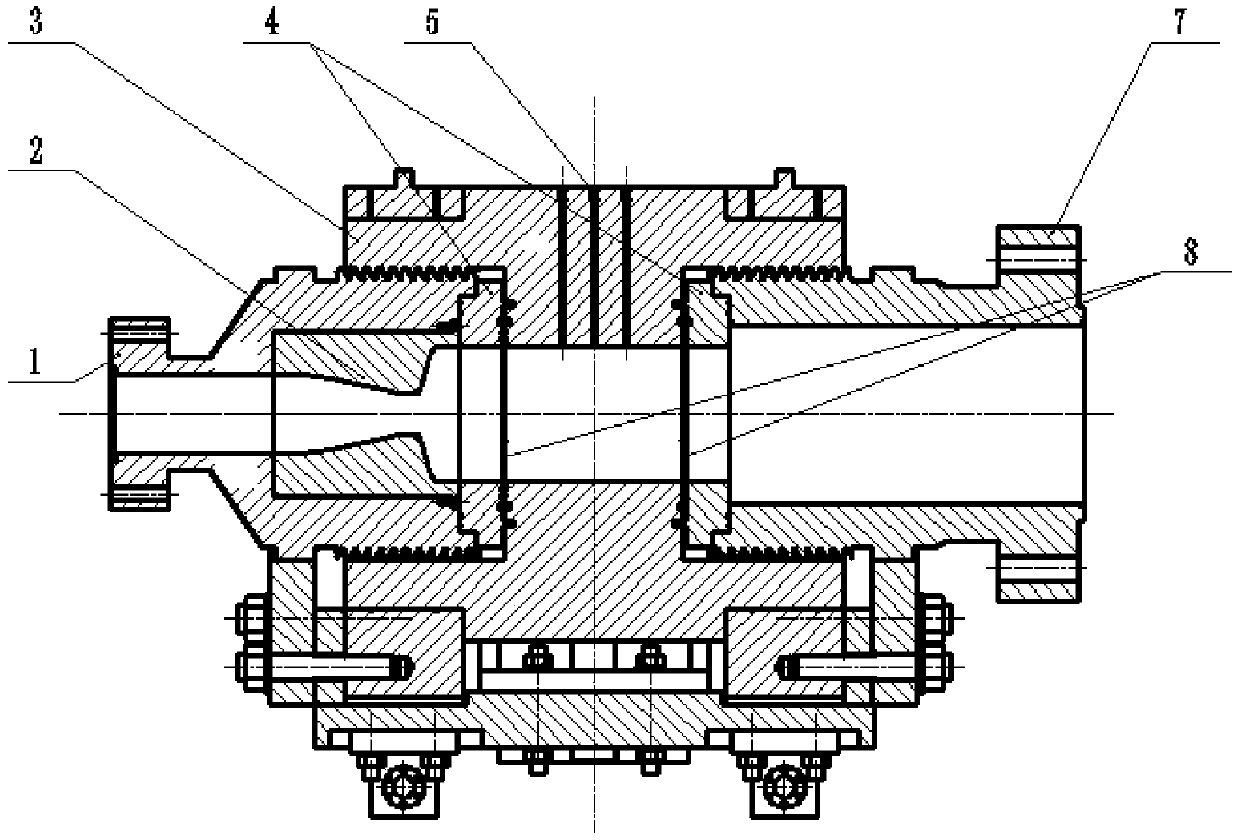

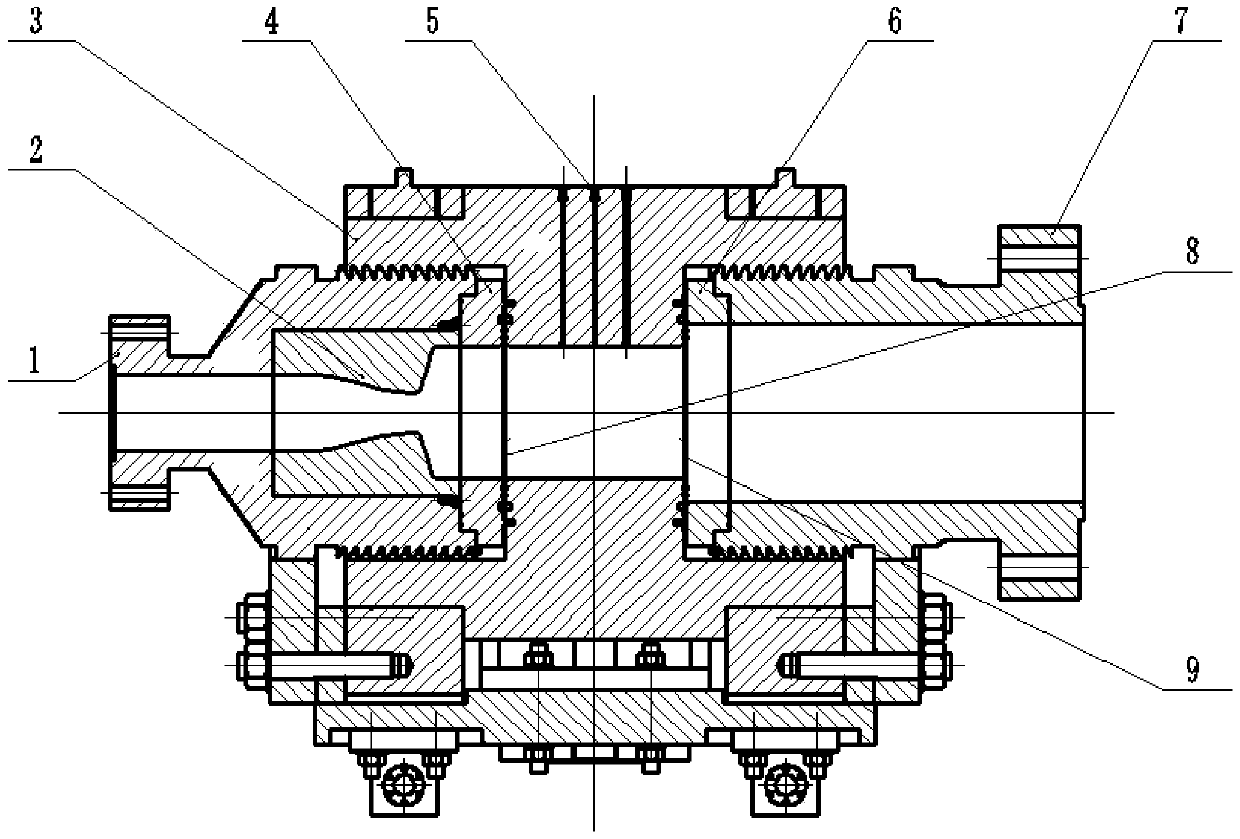

[0020] In order to reduce the manufacturing cost of the wind tunnel clamping device; save the switching time of different working conditions in the wind tunnel; reduce the airflow impact caused by the difference in the inner diameter of the two ends of the clamping mechanism after the membrane is broken, the present invention provides a double-membrane constant pressure The clamping device for membrane rupture and single-membrane impact membrane rupture realizes double-membrane constant-pressure membrane rupture and single-membrane impact membrane rupture by replacing the first adjustment ring 4, the second adjustment ring 6, the diaphragm 8, and the sealing gasket 9. function. At the same time, the air flow between the two ends of the clamping mechanism is throttled through the Rafal nozzle to reduce the impact of the airflow caused by the diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com