Experimental system for simulating fuel spray wetted walls

An experimental system and fuel technology, applied in the direction of internal combustion engine testing, etc., can solve the problems of affecting combustion and emission, splashing of lubricating oil film, increasing fuel consumption, etc., and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

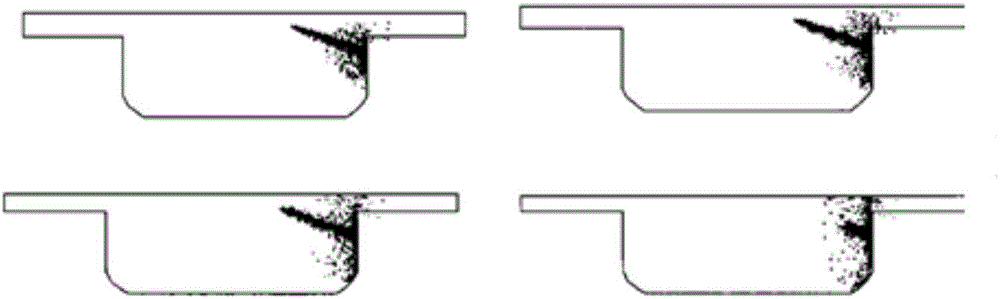

Image

Examples

Embodiment 1

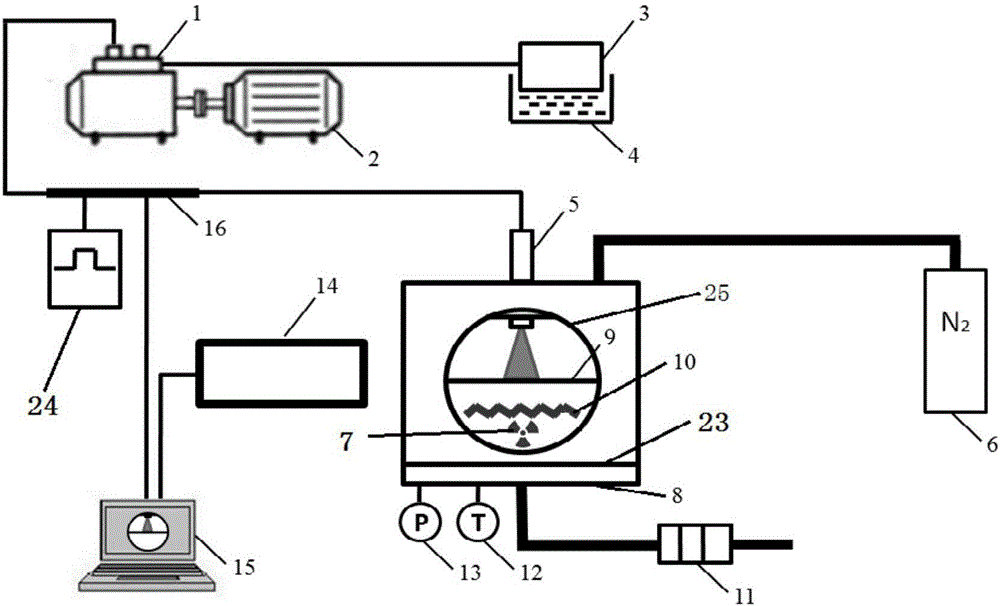

[0031] Such as figure 2 As shown, an experimental system for simulating the wetted wall of fuel spray includes a high-pressure fuel pump 1, a fuel tank 3, a fuel heating system 4, a fuel injector 5, a constant volume bomb 8, a constant volume bomb heating system, a vacuum pump 11, a temperature sensor 12, Pressure sensor 13, external test equipment 14, control system 15, high pressure fuel rail 16;

[0032] The high-pressure oil pump is connected to the driving motor 2, and the high-pressure oil pump is connected to the fuel tank, and the fuel tank is put into the fuel heating system;

[0033] The material of the constant volume bomb 8 is stainless steel, the top of the constant volume bomb is provided with the fuel injector, the constant volume bomb is connected with the high-pressure oil pump through the fuel injector, the bottom of the fuel injector is a spray hole, and the fuel injector is sprayed. The hole goes deep into the internal chamber of the constant volume bomb;...

Embodiment 2

[0045] An experimental system for simulating the wet wall of fuel spray, including high-pressure fuel pump, fuel tank, fuel heating system, fuel injector, constant volume bomb, constant volume bomb heating system, vacuum pump, temperature sensor, pressure sensor, external test equipment, control system, High pressure fuel rail;

[0046] The high-pressure oil pump is connected to the driving motor, and the high-pressure oil pump is connected to the fuel tank, and the fuel tank is put into the fuel heating system;

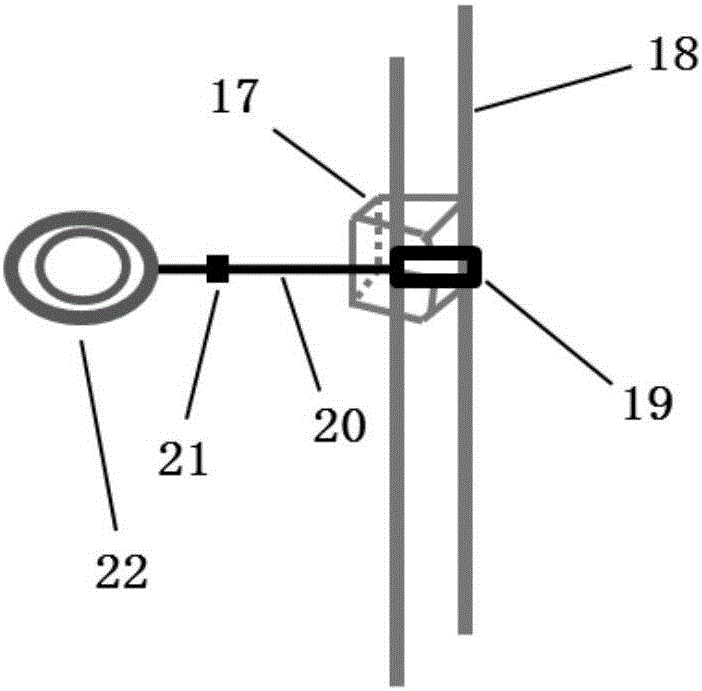

[0047] The material of the constant volume bomb is stainless steel, the top of the constant volume bomb is provided with the fuel injector, the constant volume bomb is connected with the high-pressure oil pump through the fuel injector, and the bottom of the fuel injector is a spray hole. Go deep into the inner chamber of the constant volume bomb; four vertical outer walls of the constant volume bomb are provided with windows, and a side end cover is arranged between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com