Packaging structure of fibrous wearable sweat sensor

A kind of encapsulated structure, fibrous technology, applied in the field of biosensing, can solve problems such as inability to collect and transmit sweat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

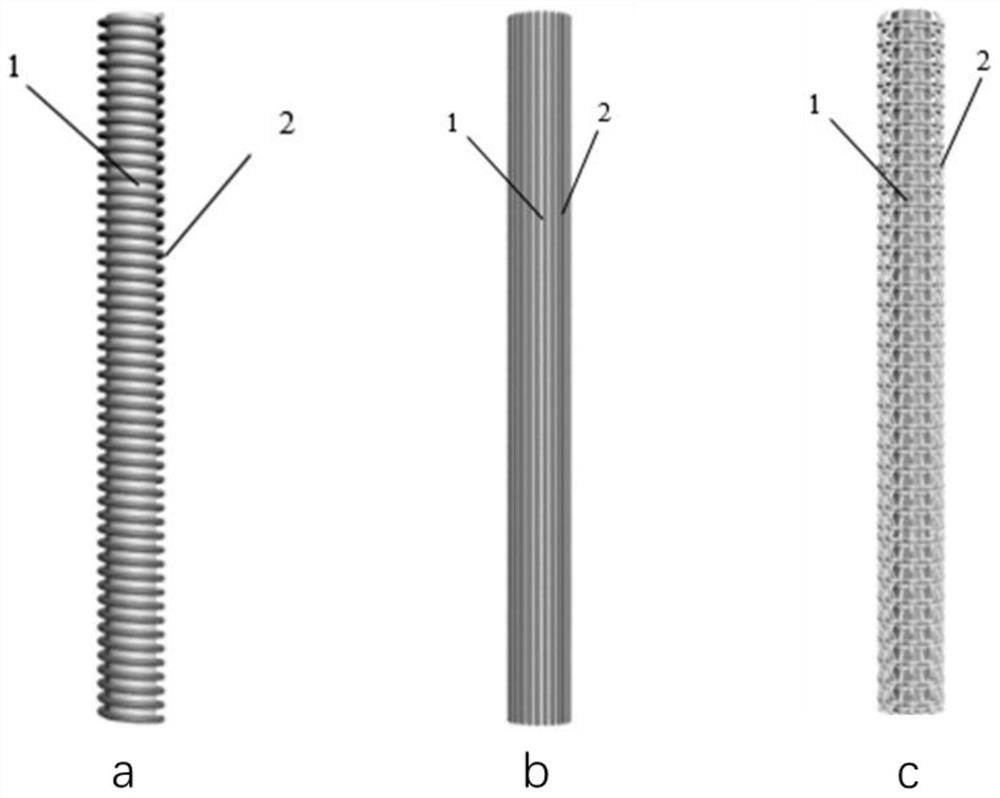

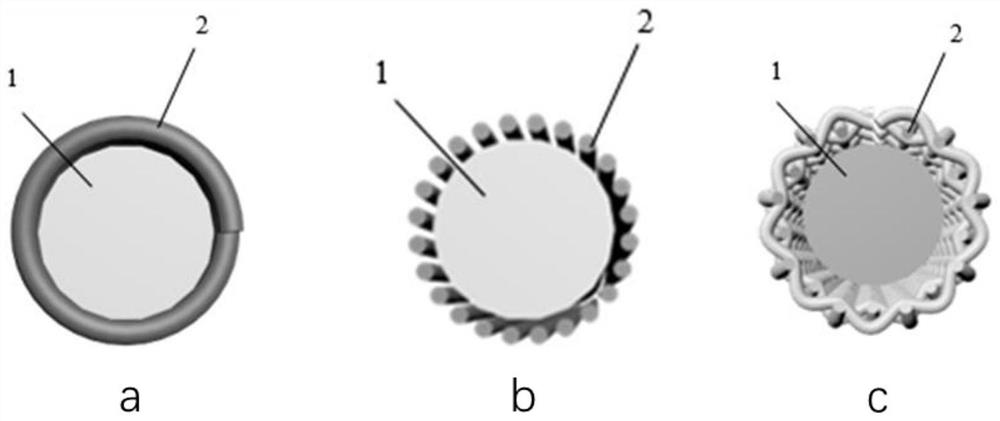

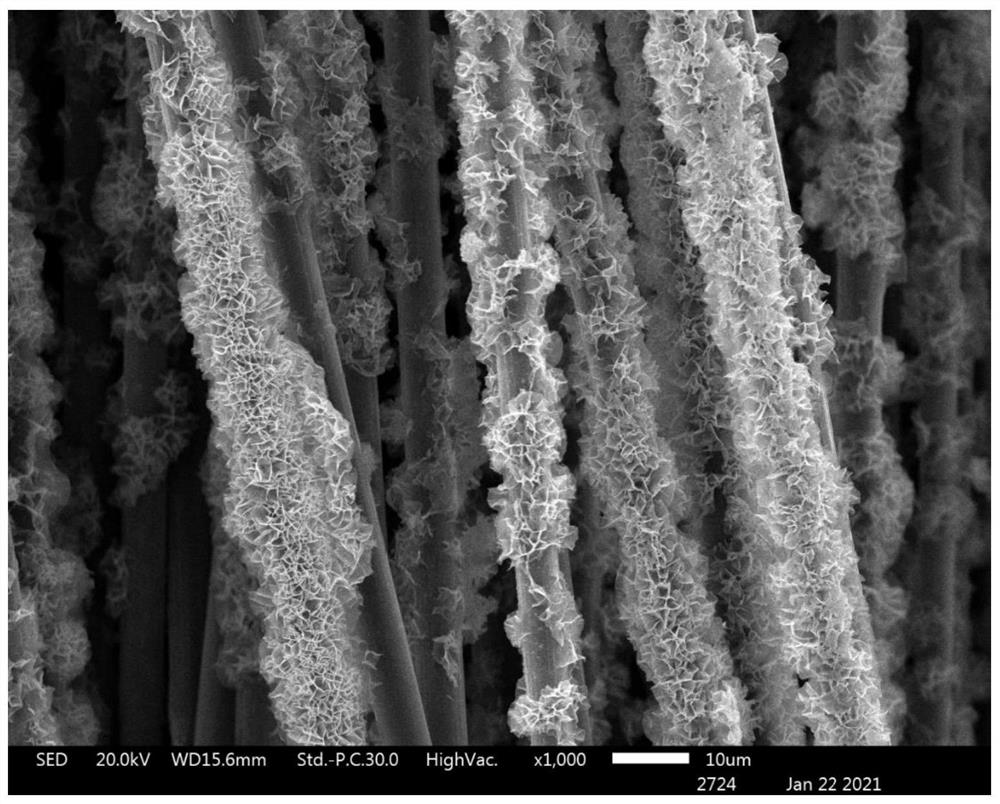

Embodiment 1

[0050] A packaging structure of a fibrous wearable sweat sensor. The carbon fiber with glucose oxidase fixed on the surface is used as the electrode core layer, and the cotton yarn is wound on the electrode in a helical shape. The distance between two adjacent helices is 10 μm. It is used for The detection limit of glucose in sweat is 50nmol / L.

Embodiment 2

[0052] A packaging structure of a fibrous wearable sweat sensor. Compared with Example 1, the difference is that the carbon fiber with lactic enzyme fixed on the surface is used as the electrode core layer, and several cotton yarns are wrapped on the electrode in parallel. The distance between the cotton yarns is 6 μm, which is used to detect lactic acid in sweat, and the detection limit is 500 nmol / L.

Embodiment 3

[0054] A packaging structure of a fibrous wearable sweat sensor. Compared with Example 1, the difference is that several cotton yarns are crisscrossed and coated on the electrodes, and the distance between two adjacent cotton yarns in the transverse direction is 6 μm. The distance between two adjacent cotton yarns in the longitudinal direction is 4 μm, which is used for the detection of glucose in sweat, and the detection limit is 50 nmol / L for sensing detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com