Device for monitoring micro-water density of SF6 on line

A micro-water density, SF6 technology, applied in the direction of measuring devices, electric heating devices, specific gravity measurement, etc., can solve the problems of performance degradation, sensor accuracy can not fully meet the technical index requirements, can not meet the operation monitoring requirements in extremely cold regions, etc., to achieve performance Safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

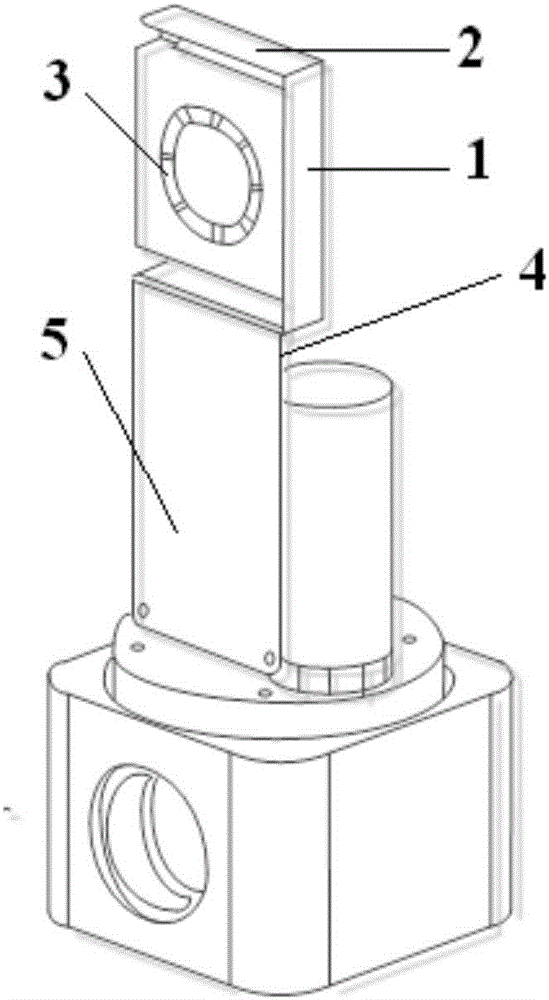

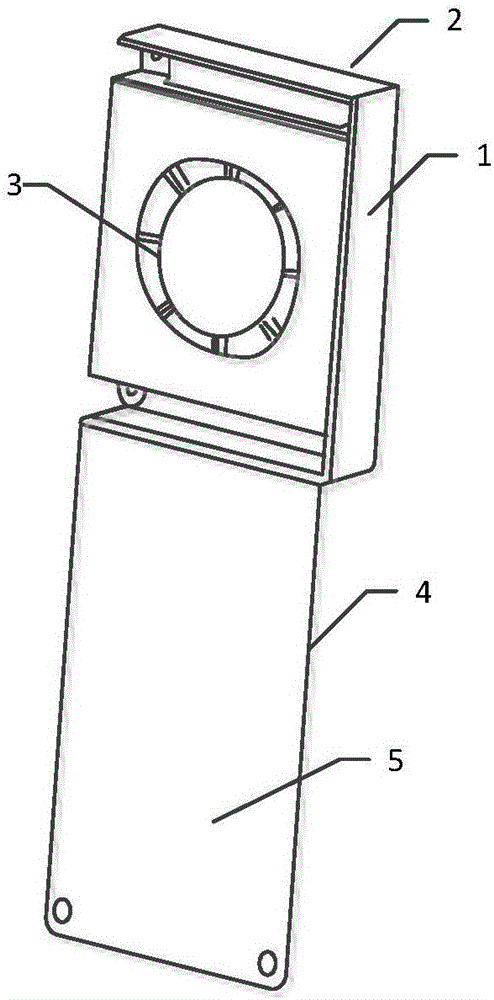

[0022] In order to have a clearer understanding of the technical features, objectives and effects of the present invention, the specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

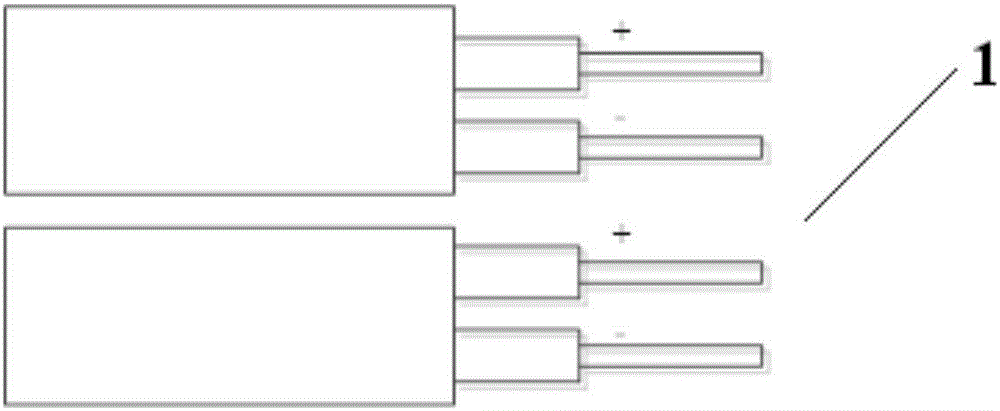

[0023] Such as figure 1 As shown, the device of the present invention for online monitoring of SF6 micro-water density includes a sampling air chamber, a ventilation interface, a processor, a display unit, and an antifreeze auxiliary heat module. The sampling gas chamber, ventilation interface, processor and display unit constitute the monitoring unit. The pressure sensor, temperature sensor and dew point sensor connected to the signal processor are installed in the sampling gas chamber. The processor collects information from the pressure sensor, temperature sensor and dew point sensor. The signal is judged and the result is sent to the display unit for display.

[0024] The antifreeze auxiliary heat module is installed inside the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com