Mask sealing degree tester

A technology of tightness and tester, which is applied in the field of permeability testing of various masks, can solve the problems of no accurate test of mask tightness, inaccurate, time-consuming and labor-intensive test results, etc., and achieves simple structure, accurate measurement, and operation. Time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

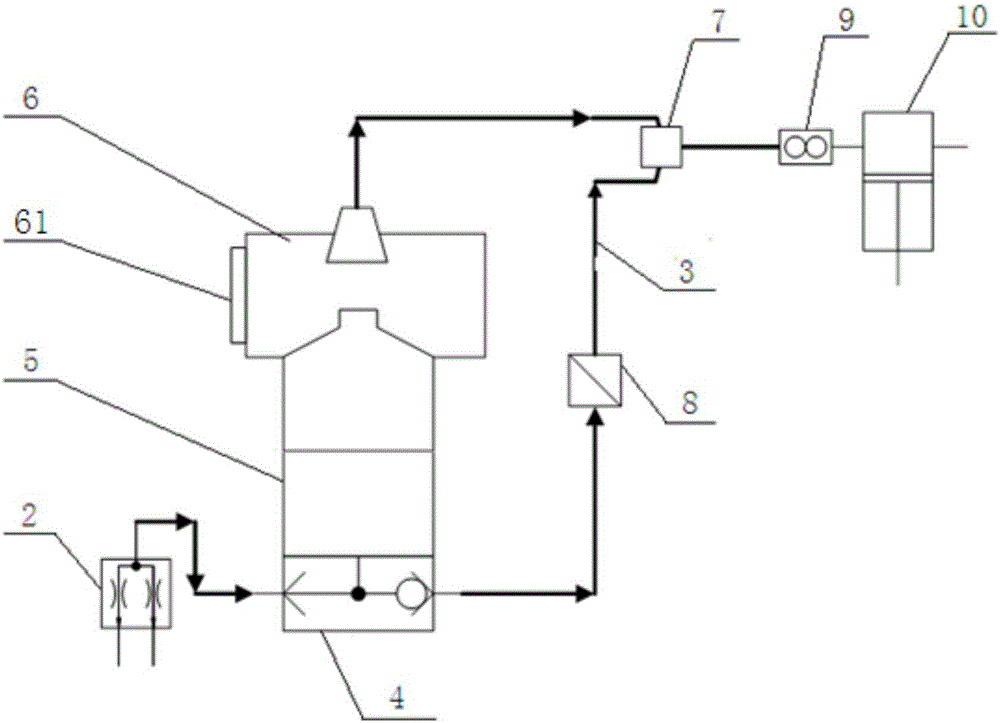

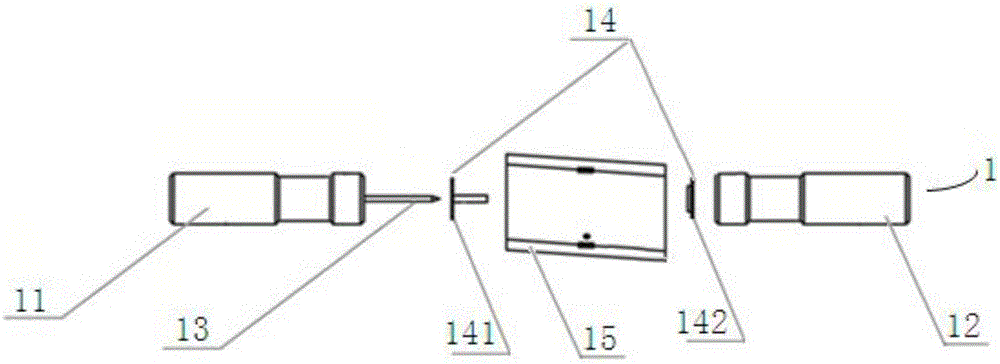

[0022] Such as Figure 1~2 As shown, the mask fit tester of the present invention includes a mask puncture assembly 1, a two-position three-way solenoid valve 2, an air connection pipe 3, a flow divider 4, a particle growth unit 5, a particle detection unit 6, a three-way 7, a high-efficiency Filter 8, flow meter 9, suction pump 10 and control unit.

[0023] The mask puncture assembly 1 is used to collect the gas in the mask to be tested. The mask puncture assembly 1 is fixedly connected to an air inlet of the two-position three-way solenoid valve 2 through a sampling tube, and the other air inlet of the two-position three-way solenoid valve 2 is connected to the atmos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com