High-precision numerical control system for four-roll veneer reeling machine based on machine vision

A four-roller rolling machine, machine vision technology, applied in general control system, control/adjustment system, computer control, etc., can solve the problem of high defective rate, low production efficiency, and inaccurate monitoring of the rolling condition of the rolling machine, etc. problems, to achieve good accuracy, improve quality and efficiency, and improve the effect of inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

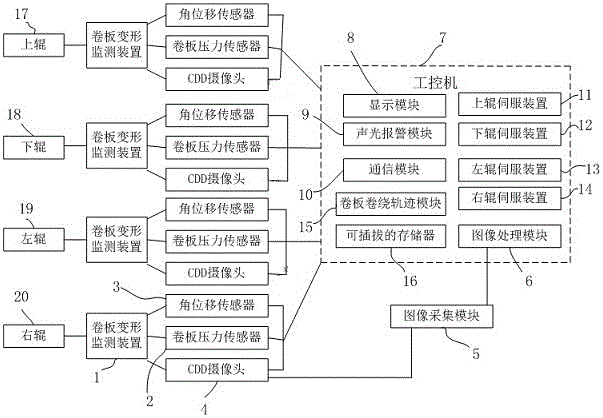

[0013] Such as figure 1 As shown, the high-precision numerical control system of the four-roller plate bending machine based on machine vision includes four pairs of coiling deformation monitoring devices 1 respectively connected to the upper roll, lower roll, left roll, and right roll. The monitoring device 1 includes a coil pressure sensor 2, an angular displacement sensor 3, and a CDD camera 4, and these four CDD cameras 4 are respectively connected to the image processing module 6 and the industrial computer 7 through the image acquisition module 5; the industrial computer 7 also Connect display module 8, sound and light alarm module 9, communication module 10, upper rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com