Trigonometric function acceleration and deceleration control method for high-quality machining

A technology of acceleration and deceleration control and trigonometric functions, applied in digital control, general control system, program control, etc., can solve problems such as machine tool vibration, jerk discontinuity, and affecting processing quality

Inactive Publication Date: 2017-05-10

中国科学院沈阳计算技术研究所有限公司

View PDF6 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional linear acceleration and deceleration control method has a small amount of calculation and simple control, but there is a sudden change in acceleration during acceleration or deceleration, which can easily cause vibration of the machine tool and affect the processing quality

During an acceleration or acceleration process of the S-curve speed planning algorithm, the speed equation is calculated in two or three segments, the control is more complicated, and the jerk changes four times in an acceleration or deceleration segment. When complex parts are used, it may cause vibration of the tool

The cubic polynomial speed planning algorithm is simple to control and can realize continuous changes in acceleration, but its jerk is still discontinuous. During one acceleration and deceleration process, its jerk mutation will still change twice, so this method is also not conducive to high quality processing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

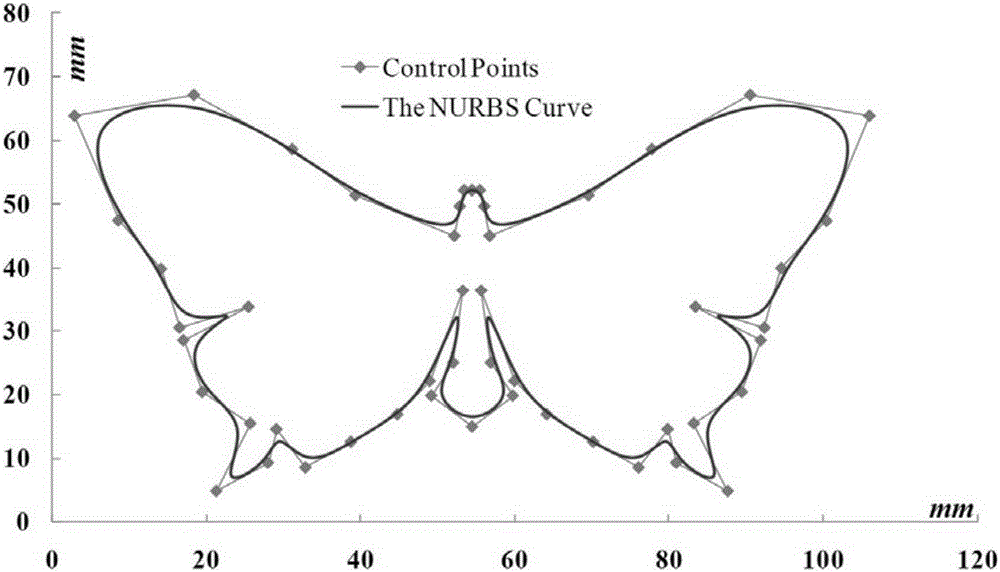

[0075] Embodiment: the inventive method is carried out emulation verification on PC, used programming software is MicrosoftVisual Studio 2010, uses C language to program, the spline curve that selects here is NURBS (Non-Uniform Rational B-Spline) curve.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

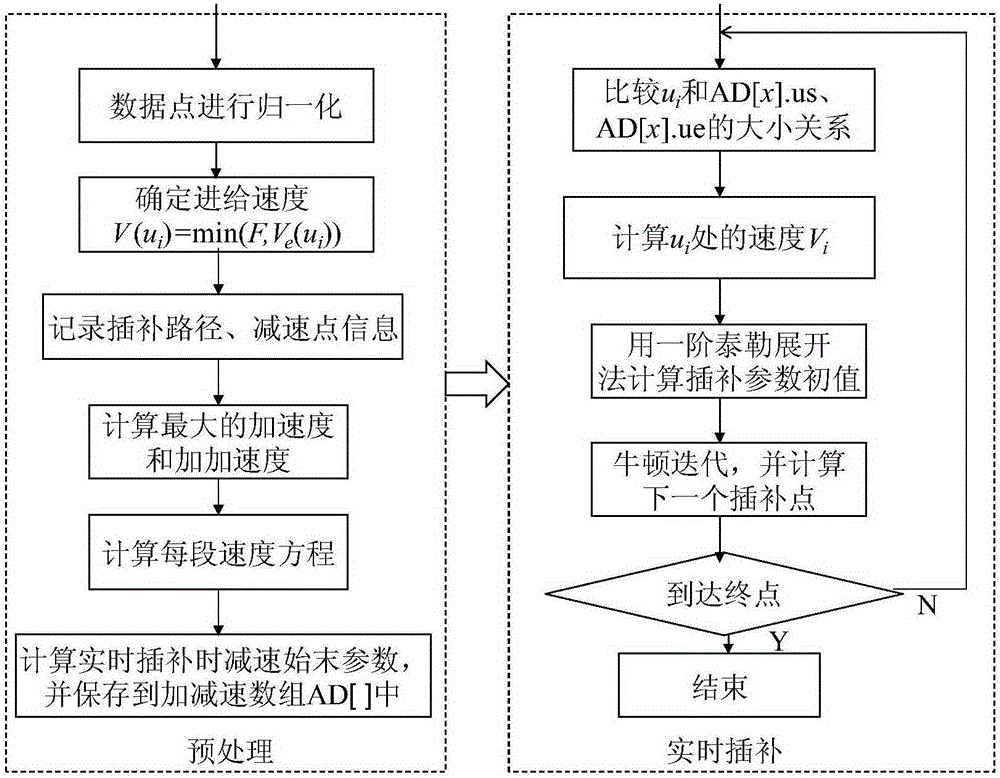

The invention relates to a trigonometric function acceleration and deceleration control method for high-quality machining. The method comprises a pre-interpolation stage and a real-time spline interpolation stage. In the preprocessing stage, a path to be machined is quickly interpolated, key information is recorded, and the trigonometric function speed equation in each acceleration and deceleration section is calculated. In the real-time spline interpolation stage, the real-time feed rate of a cutter is calculated according to the recorded information and the speed equations in the preprocessing stage, and then, next interpolation parameter is calculated in real time using a Newton iteration method, and real-time spline interpolation is carried out. The method is simple in control. Continuous change of speed, acceleration and jerk in the process of machining is realized, and fluctuation in feed rate is reduced. Therefore, the machining precision is guaranteed, overshoot caused by high-speed machining is eased, and flexible acceleration and deceleration control on a servo shaft is achieved. The method is suitable for high-quality processing.

Description

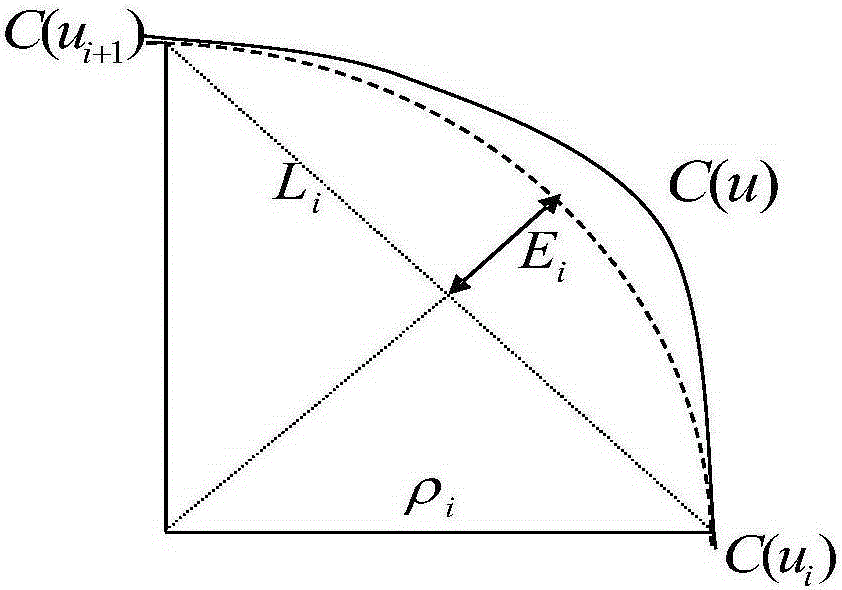

technical field [0001] The invention relates to the technical field of numerical control machining, in particular to a trigonometric function acceleration and deceleration control method for high-quality machining. Background technique [0002] Numerical control technology is the basis and core of modern advanced manufacturing technology, which reflects a country's manufacturing technology level to a large extent and is an important symbol to measure industrial modernization. [0003] Realizing high-speed machining and high-precision machining are two important goals of the CNC system. The speed of processing is directly related to the efficiency of processing, while the processing accuracy directly affects the quality of processing. With the development of modern science and technology and production, the field of machining and measurement puts forward higher and higher speed and precision requirements. High-speed, high-precision, and high-quality CNC machining puts forwa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G05B19/4103

CPCG05B19/4103G05B2219/34085

Inventor 杨东升王允森刘荫忠尹震宇马爽

Owner 中国科学院沈阳计算技术研究所有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com