Plasma jet flow generation device

A generation device and plasma technology, applied in the direction of plasma, discharge tube, electrical components, etc., can solve the problems of shortening the length of plasma jet plume, reducing the energy of plasma jet, and short length of plasma plume, etc. Uniform and stable in vitro, easy to discharge, and large spraying distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Next, the present invention will be described in detail in conjunction with the accompanying drawings

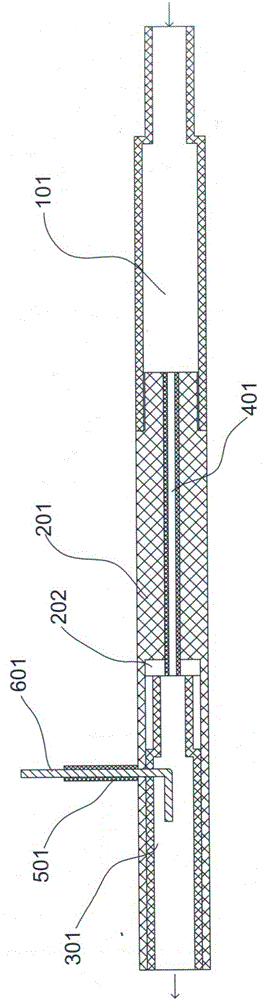

[0019] like figure 1 In the shown plasma jet generating device, the air pipe 101 is a reducing pipe made of insulating material, one end of which is an air inlet end, and the other end is an air outlet end, the inner diameter of the air inlet end is smaller than the inner diameter of the air outlet end, and the inner diameter of the air pipe is The outlet end is screwed to the discharge seat 201 made of insulating material, and a cavity 202 is opened inwardly from the non-connecting end of the discharge seat. There is a discharge tube 301 made of insulating material in the cavity, and the discharge tube is a reducing tube. , one end of the discharge tube is the air intake end, and the other end is the injection end, the inner diameter of the air intake end is smaller than the inner diameter of the injection end; the air intake end of the discharge tube communicates wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com