Sucker and adsorption method thereof

A suction cup and main body technology, which is applied in the field of semiconductor device manufacturing, can solve problems such as inability to generate adsorption force, inability to effectively absorb warped substrates, and 04 adsorption design not involved in warped substrates, achieving effective adsorption, high adaptability to working conditions, The effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiment of the invention will be described in further detail below in conjunction with the accompanying drawings.

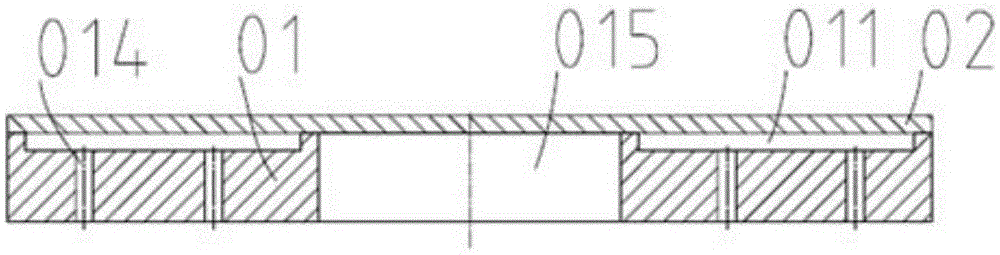

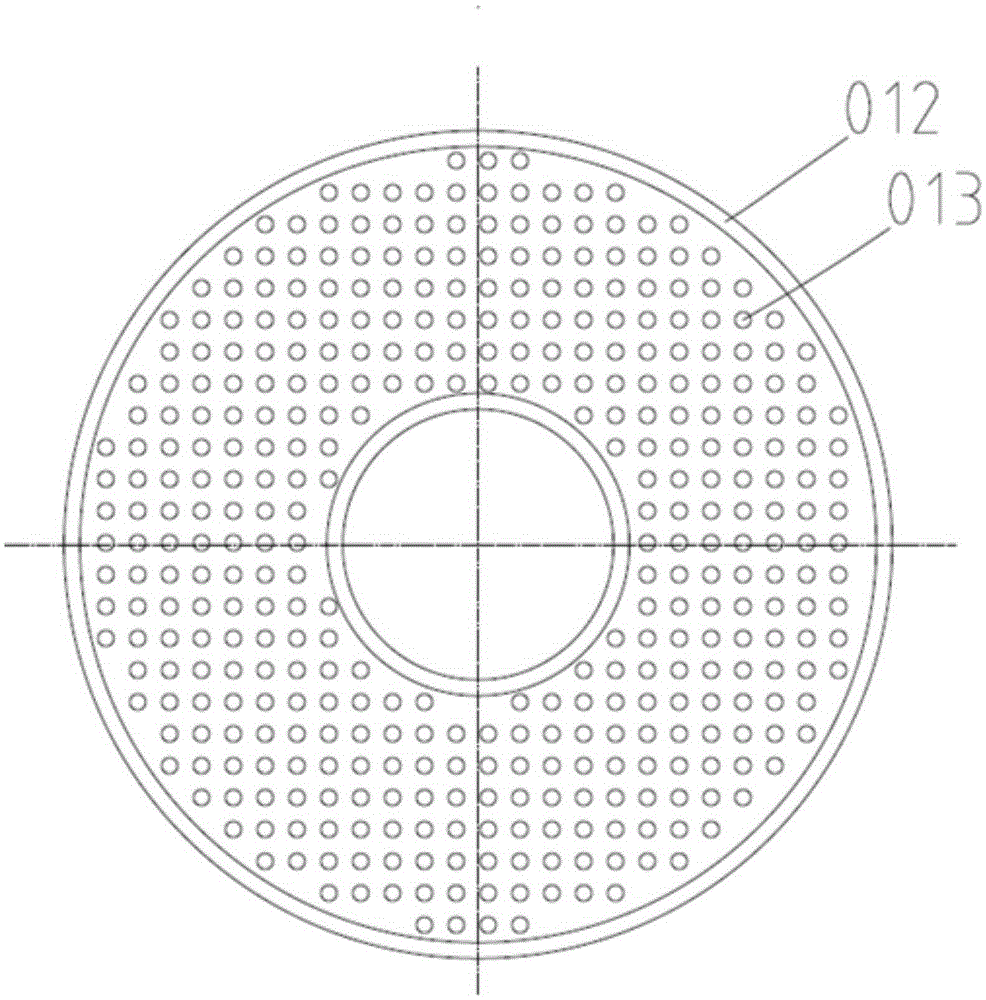

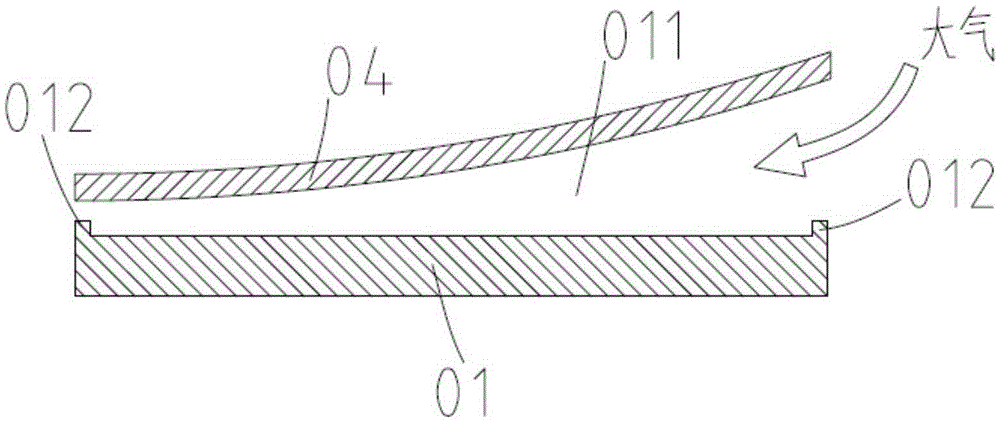

[0035] Such as Figure 4 with Figure 5 As shown, the present invention provides a suction cup, including a suction cup body 03, wherein, the center of the suction cup body 03 is provided with a through hole 035 for substrate transfer, and the suction cup body 03 is provided with at least one protrusion protruding from the suction cup body 03. And the sealing ring 032 concentrically distributed with the through hole 035, the sealing ring 032 is provided with an annular groove 031, and the annular groove 031 is provided with a number of vacuum holes 034 communicated with the external vacuum source, correspondingly the vacuum The hole 034 passes through the suction cup body 03 corresponding to the annular groove 031 and communicates with the vacuum source. When the substrate 04 is adsorbed, a vacuum is introduced from the vacuum hole 034, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com