Novel kneading method and applications of cathode slurry

A negative electrode slurry, slurry technology, applied in chemical instruments and methods, mixers with rotary stirring devices, mixers, etc., can solve the problems of incomplete dispersion, increase the difficulty of dispersion, increase the dispersion time, etc. Conducive to industrial production, solve poor dispersion, reduce the effect of stirring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

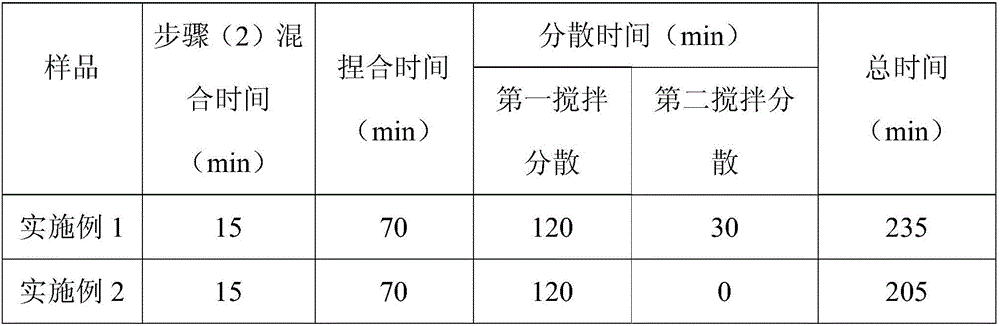

Embodiment 1

[0044] (1) Take by weighing 350kg artificial graphite, 3.56kg conductive agent SP, 16.31kg binder CMC (solid content: 92%), 14.97kg binder SBR (solid content: 48.5%) and 404kg solvent;

[0045] (2) CMC is dissolved with the solvent of 30wt% (121.2kg), obtains the CMC of dissolving;

[0046] (3) Mix artificial graphite and conductive agent SP for 15 minutes to obtain uniform mixed powder;

[0047] (4) Add 40wt% (161.6kg) solvent to the mixed powder obtained in step (3), and knead for 70min to obtain a bonded slurry;

[0048] (5) Add the dissolved CMC obtained in step (2) and the remaining 30wt% (121.2kg) solvent to the bonding slurry obtained in step (4), and carry out the first stirring and dispersing for 120min;

[0049] (6) Add SBR, carry out the second stirring and dispersing for 30 minutes, and obtain negative electrode slurry.

[0050] The negative electrode slurry obtained in this embodiment was tested, and the test results are shown in Table 1 and Table 2.

Embodiment 2

[0052] (1) Take by weighing 350kg artificial graphite, 3.56kg conductive agent SP, 50kg LA133 (solid content 15%) and 300kg solvent;

[0053] (2) Mix artificial graphite and conductive agent SP for 15 minutes to obtain uniform mixed powder;

[0054] (3) Add 40wt% (120kg) solvent to the mixed powder obtained in step (2), and knead for 70min to obtain a bonding slurry;

[0055] (4) Add LA133 and the remaining 60 wt% solvent to the adhesive slurry obtained in step (3), and stir and disperse for 120 minutes to obtain negative electrode slurry.

[0056] The negative electrode slurry obtained in this embodiment was tested, and the test results are shown in Table 1 and Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com