High power optical fiber laser key point protection device

A fiber laser and protection device technology, which is applied to lasers, laser components, phonon exciters, etc., can solve the problem of destroying thermal balance and achieve the effect of avoiding thermal load damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

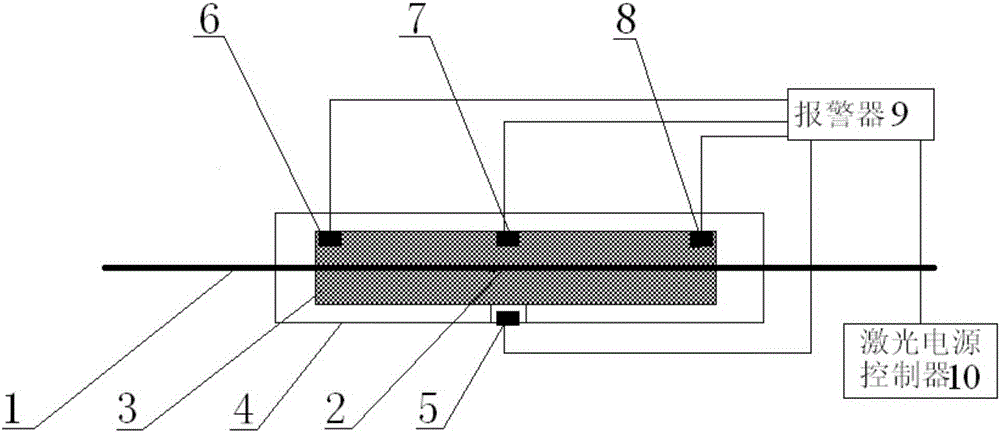

[0015] The key point protection device of high-power fiber laser includes an optical fiber 1 with a melting point position 2 on it, which is characterized in that heat-conducting and light-conducting adhesive 4 is wrapped around the optical fiber 1 centered on the melting point position 2 and evenly distributed , and install the optical fiber 1 wrapped with the heat-conducting and light-conducting adhesive 4 on the heat-dissipating bottom plate 3 together, and a pressure sensor 5 is installed in the middle above the heat-conducting and light-conducting adhesive 4 on one side of the optical fiber 1, and the heat-conducting on the other side of the optical fiber 1 One end, the middle and the other end above the light guide adhesive 4 are respectively equipped with a first miniature temperature sensor 6, a second miniature temperature sensor 7 and a third miniature temperature sensor 8, a pressure sensor 5, a first miniature temperature sensor 6, and a second miniature temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com