Synchronous rectification control method of flyback converter and its control module

A flyback converter and synchronous rectification technology, applied in the direction of converting DC power input to DC power output, AC power input converting to DC power output, control/regulation systems, etc. large, reduce the reliability of the device, etc., to achieve the effect of high efficiency and simple application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

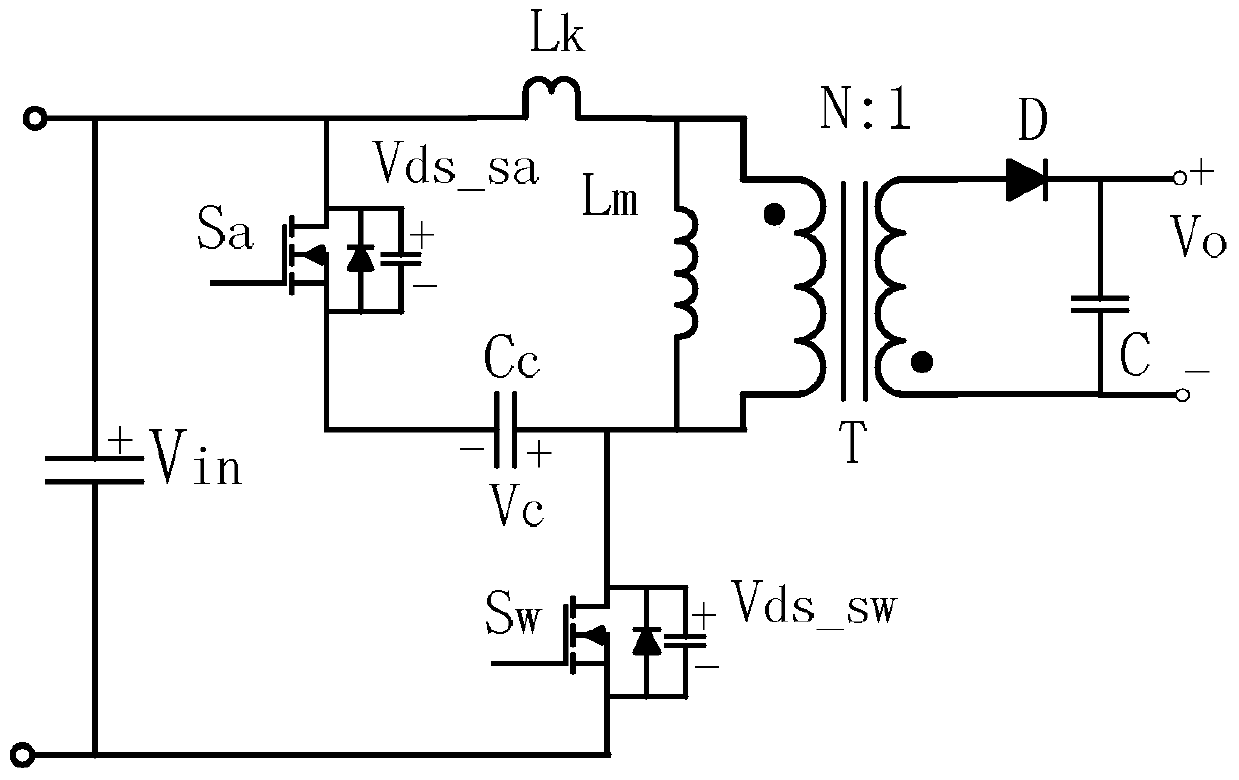

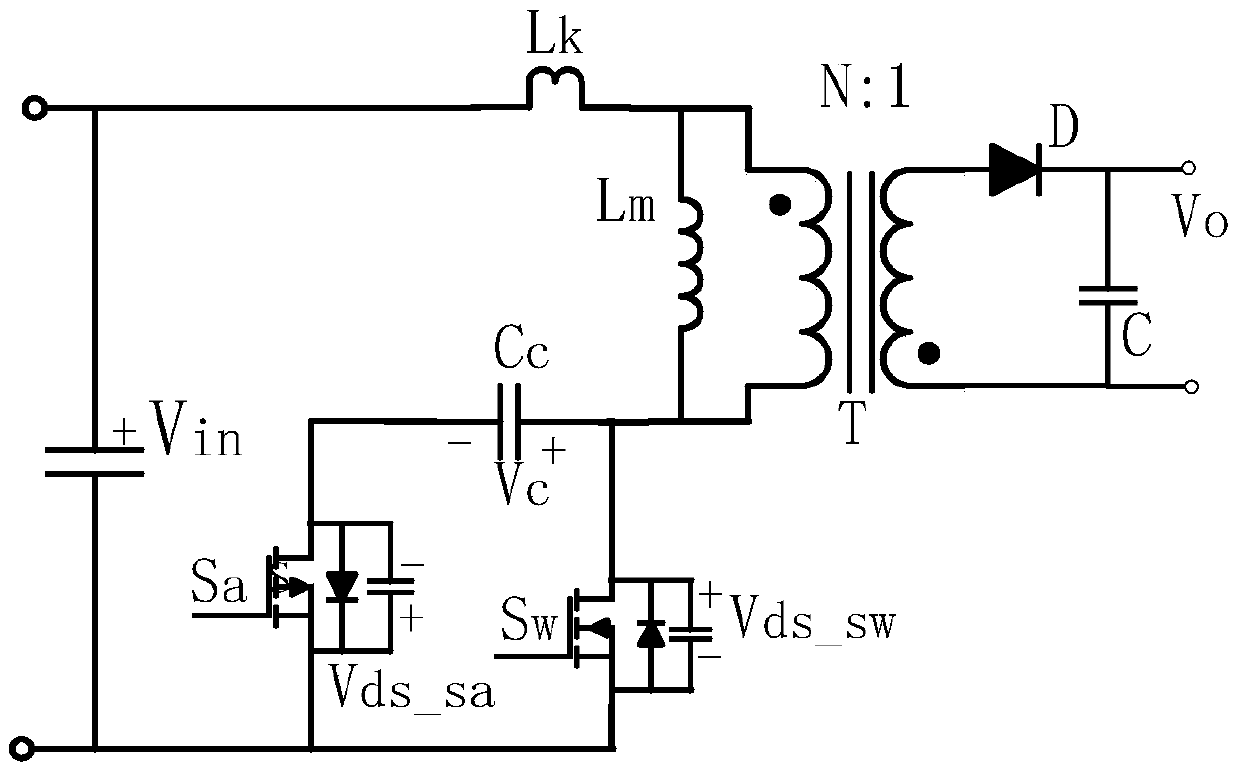

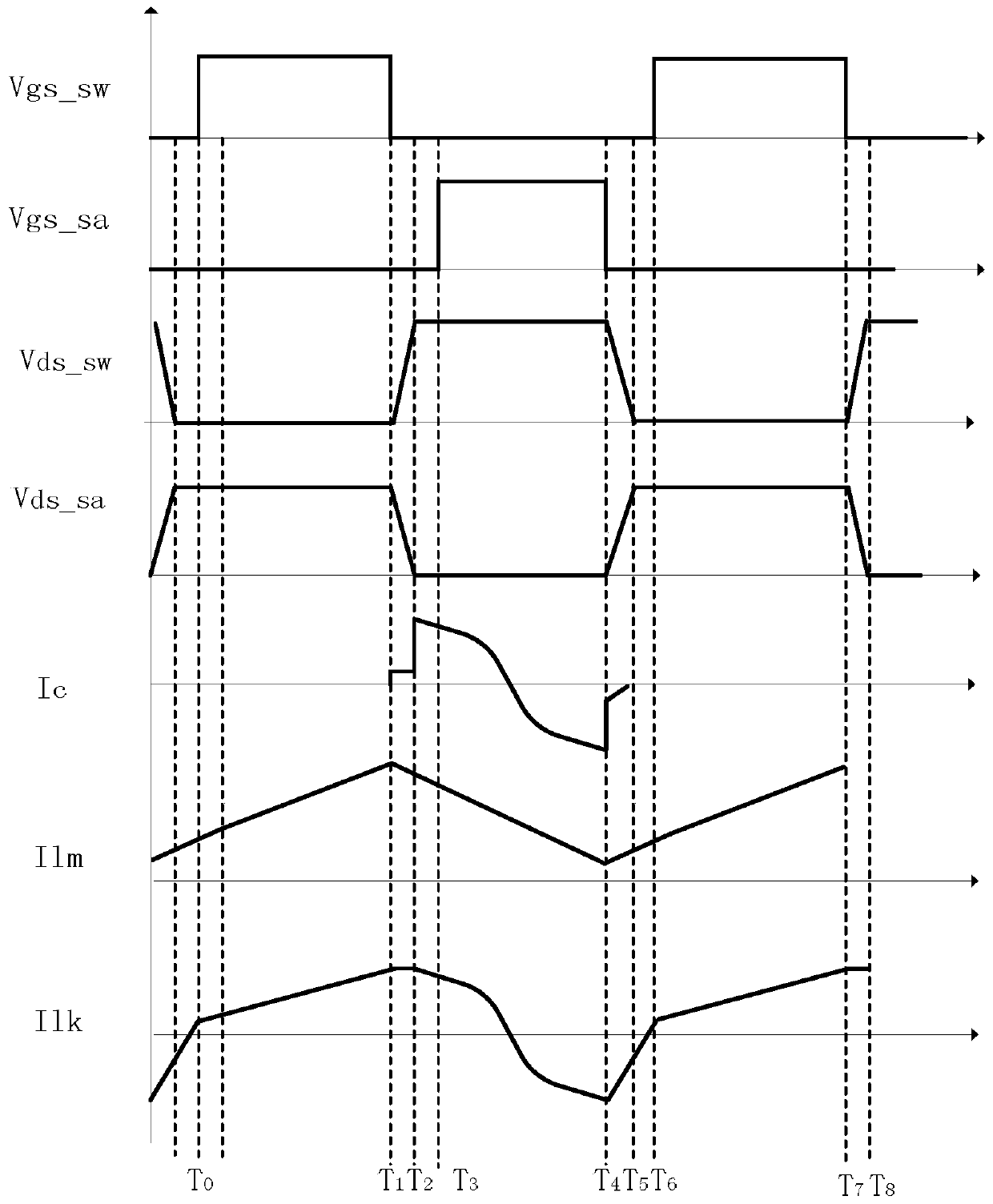

[0042] image 3 Shows the circuit schematic diagram of the flyback converter of the first embodiment of the present invention, a flyback converter, on the basis of an asymmetric flyback active clamp converter, the synchronous rectifier Q1 is applied to the synchronous The rectification circuit device also includes an integrated circuit IC1 of a synchronous rectification control module (for the sake of brevity, integrated circuit IC1, hereinafter referred to as IC1), the connection relationship of the synchronous rectification control module IC1 using the present invention is: asymmetric flyback active clamp The bit converter includes a primary side circuit and a secondary side circuit, the primary side circuit includes a clamping circuit, and the clamping circuit includes a clamping switch tube Sa and a clamping capacitor. The primary side circuit also includes a main switch tube Sw.

[0043] The secondary side circuit includes a synchronous rectifier tube Q1. The synchronous...

no. 2 example

[0054] Figure 7 The schematic diagram of the second embodiment is shown, the synchronous rectifier tube Q1 is applied to the synchronous rectifier circuit device, and also includes an integrated circuit IC1, and the integrated circuit IC1 adopts the technical solution in the content of the invention to control the synchronous rectifier tube Q1. The difference from the first embodiment is that the implementation method of synchronous rectification also includes a sampling resistor Rs, which is connected in series with the synchronous rectification tube, IC1 detects the voltage Vs at both ends of the sampling resistor Rs as a control signal, and IC1 adopts the synchronous rectification of the present invention to realize method, its principle is equal to the principle of embodiment 1, and will not be repeated here, Figure 7 The device shown also achieves the object of the invention.

no. 3 example

[0056] Figure 8 The schematic diagram of the third embodiment is shown, the synchronous rectifier tube Q1 is applied to the synchronous rectifier circuit device, and also includes an integrated circuit IC1, and the integrated circuit IC1 adopts the technical solution in the content of the invention to control the synchronous rectifier tube Q1. Different from the first embodiment, the synchronous rectification implementation method also includes a current transformer Ts, the transformer Ts has a primary winding and a secondary winding, the primary winding is connected in series with the synchronous rectifier tube Q1, and IC1 detects the secondary winding of the transformer Ts The current Is of the winding is used as the control signal, and IC1 adopts the method for implementing synchronous rectification of the present invention, the principle of which is the same as that of Embodiment 1, and will not be repeated here. Figure 8 The device shown also achieves the object of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com