Self-charging cloth and method for power generation by use of the self-charging cloth

A self-charging, triboelectric generator technology, applied in the field of electronics, which can solve problems such as high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

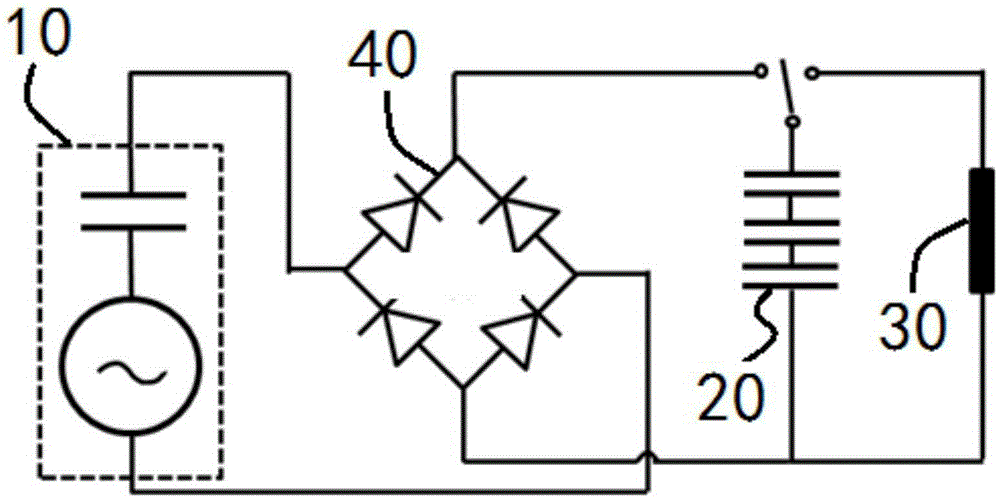

[0024] According to an embodiment of the present invention, the self-charging cloth further includes a rectifier bridge 40 connected between the friction generator part 10 and the capacitor part 20 for converting the electrical signal output by the friction generator part 10 to rectified to a DC signal. Charging of the capacitor portion 20 is thereby achieved.

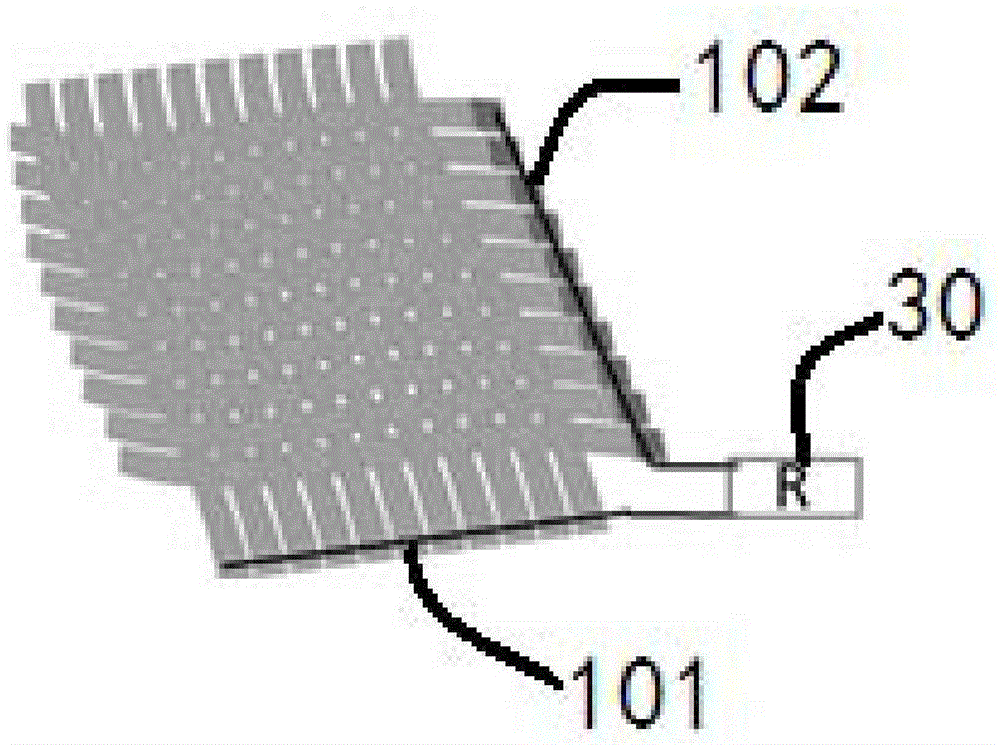

[0025] According to one embodiment of the present invention, the triboelectric generator part 10 includes a first electrode 101 and a second electrode 102 that output the electrical signal, the first electrode 101 is a cloth or wire coated with a metal film, and the The second electrode 102 is a cloth or wire coated with a metal film and a polymer film sequentially.

[0026] Wherein, the first electrode 101 and the second electrode 102 are cross-woven, preferably vertically cross-woven. For example, a plurality of the first electrodes 101 are arranged vertically, and a plurality of the electrodes 102 are transversely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com