Rubber bearing structure based on piezoelectric effect and power generating system thereof

A rubber bearing, piezoelectric effect technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, battery circuit devices, generators/motors, etc., to improve power generation and power generation efficiency, large stress changes Amplitude, the effect of improving energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

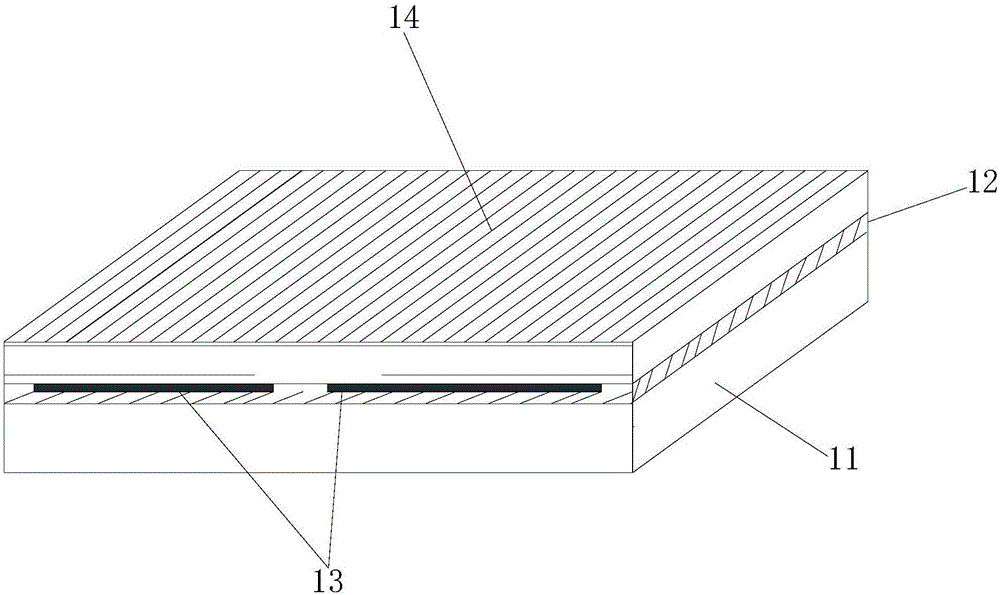

[0026] like figure 1 As shown in the figure, the rubber bearing structure based on the piezoelectric effect of the present invention includes a bottom rubber layer 11, the upper part of the bottom rubber layer 11 is provided with a stiffening plate 12, and the upper part of the stiffening plate 12 is provided with a number of parallel connected piezoelectric Sheet 13, the upper part of the piezoelectric sheet 13 is provided with a top rubber layer 14. The bottom rubber layer 11 and the top rubber layer 14 are both natural rubber.

[0027] The piezoelectric sheet 13 is pasted and fixed on the stiffening plate 12, and the adhesive can be selected from polyurethane glue, so that the bonding strength of the piezoelectric sheet 13 and the stiffening plate 12 is greater than 10Mpa, ensuring that the piezoelectric ceramic sheet and the stiffening plate 12. There is no cohesive failure between them. The coverage area of the piezoelectric sheet 13 accounts for at least 4 / 5 of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com