Machining device and machining method

A technology for processing workpieces and equipment, which is applied in the field of processing equipment and processing, can solve the problems of high manufacturing time, high unit cost, and small throughput, and achieve the effects of low unit cost, increased productivity, and minimized downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Individual and multiple features of different embodiments can be combined with one another in order to form new embodiments.

[0031] The specific embodiments can also be combined with each other in order to form further specific embodiments.

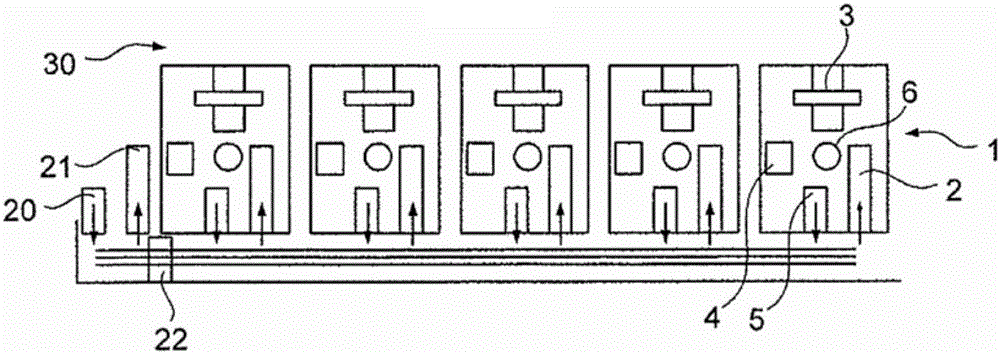

[0032] The embodiments described hereinafter are preferably suitable for machining workpieces which at least partially consist of wood, wooden materials, plastics or the like, for example in the field of the furniture and component industry. In this case, for example, solid wood boards or pressed boards, lightweight boards, sandwich boards etc. can be involved. At this point, however, it should be noted that embodiments are not limited to the machining of such materials and workpieces.

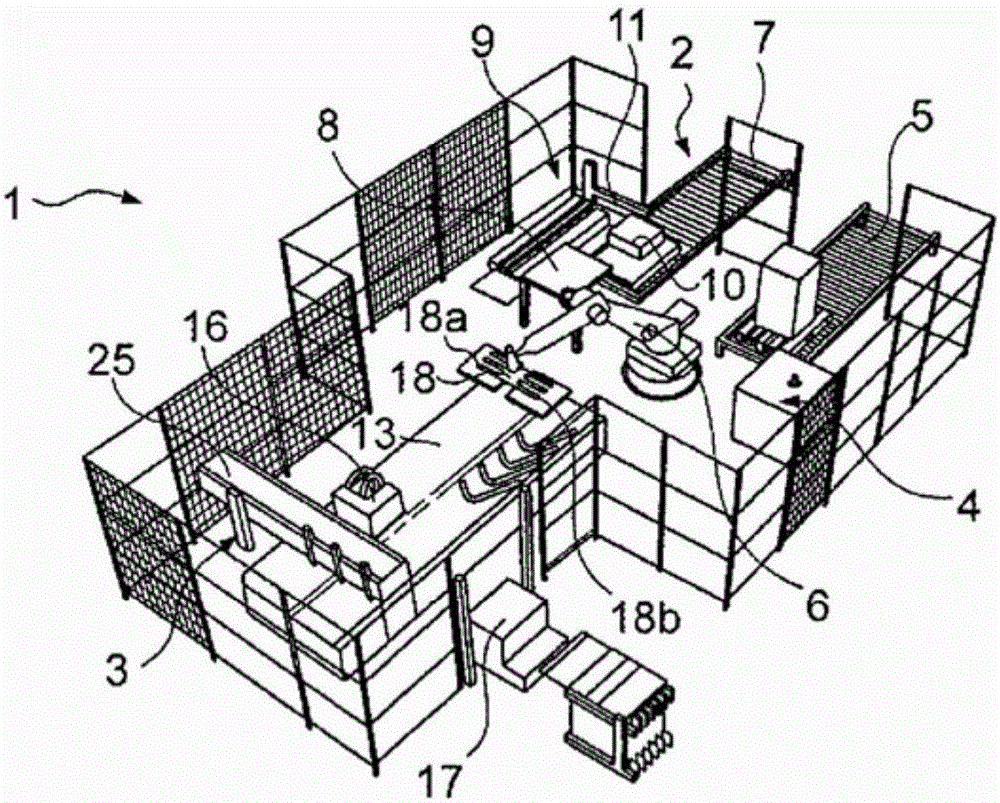

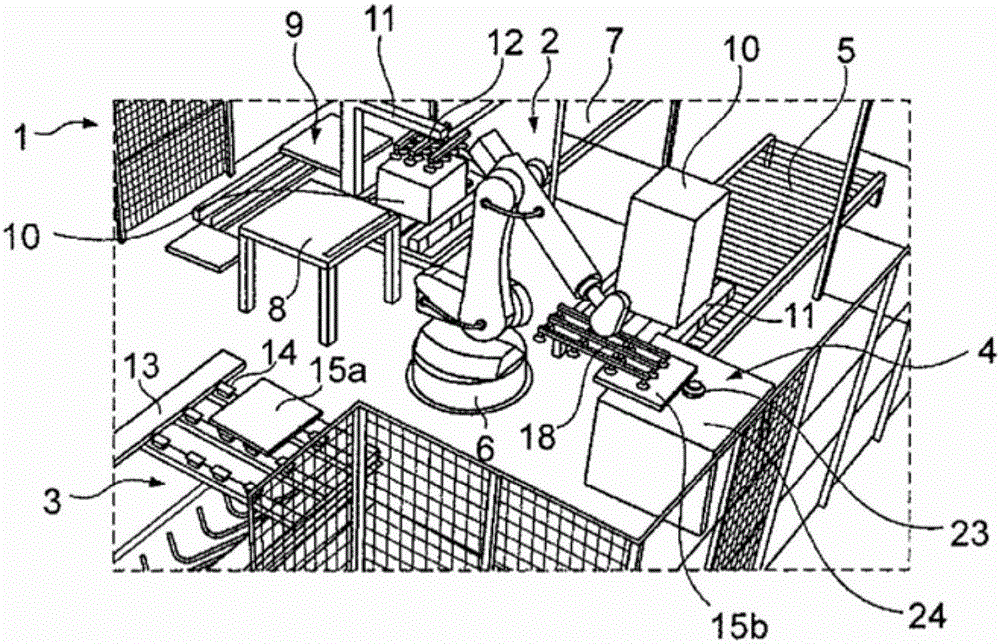

[0033] exist figure 1 with 2 The manufacturing cell 1 of the first preferred embodiment shown in the figure basically comprises fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com