Sensor unit using electro-active polymer for wireless transmission/reception of deformation information, and sensor using same

A technology of electroactive polymers and sensor units, applied in the direction of transmitting sensing components using electric/magnetic devices, electric/magnetic solid deformation measurement, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve detection and evaluation Solve problems such as limited firmness of the structure, achieve fast mechanical/electrical ductility response speed, high accuracy, high reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

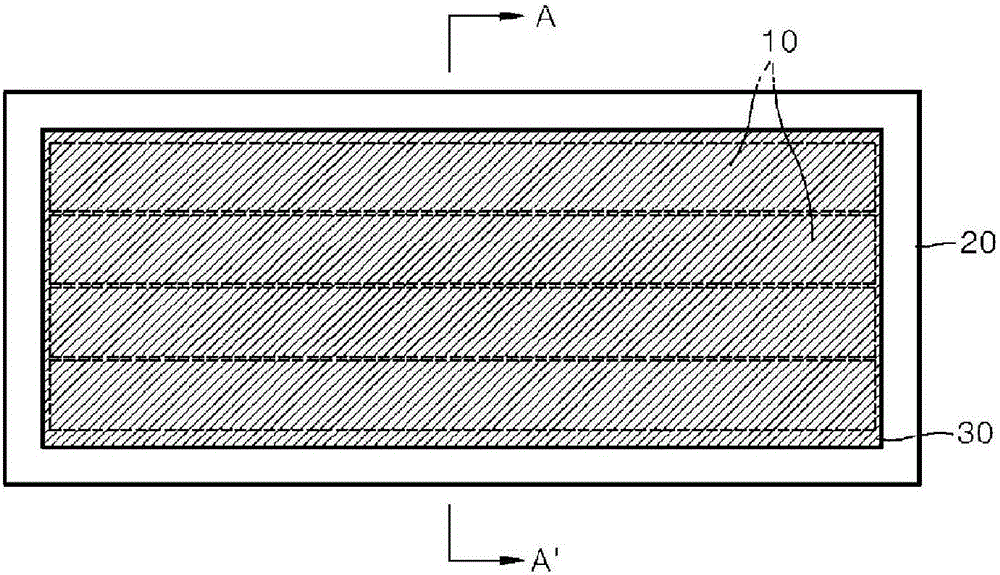

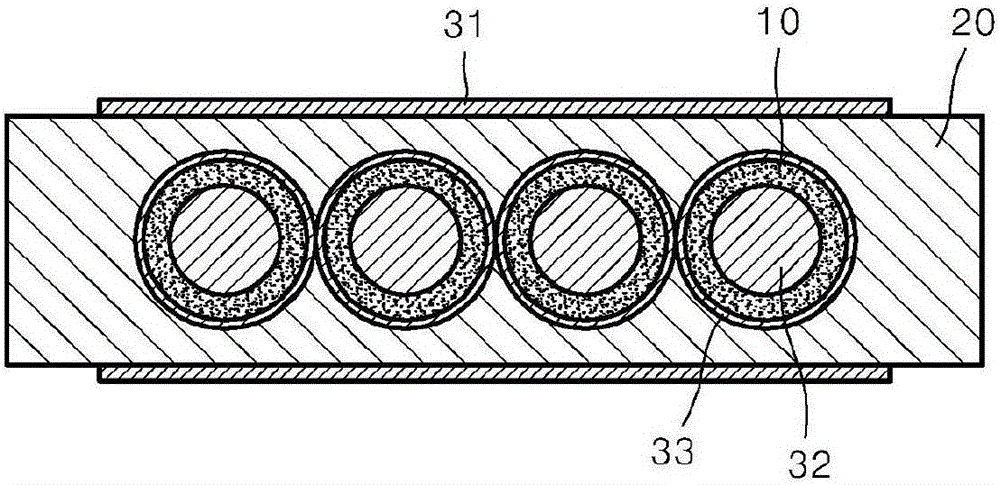

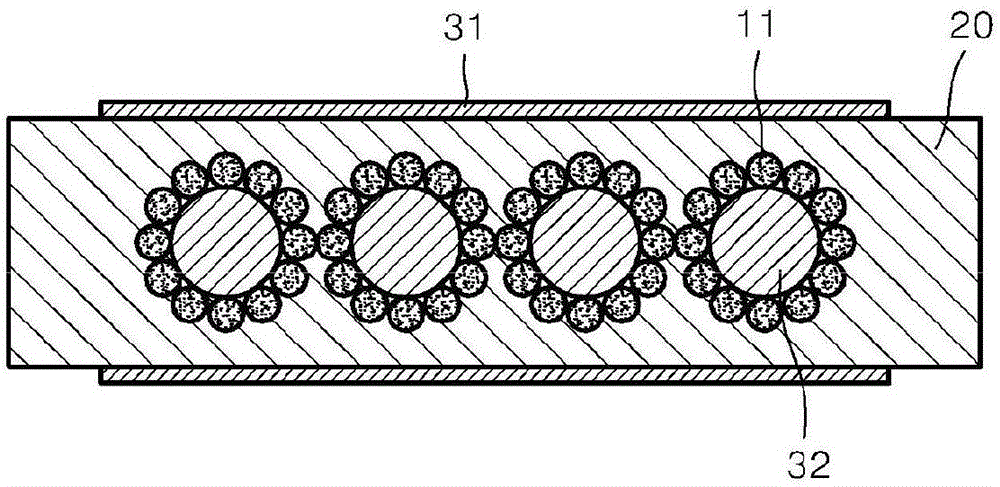

[0045] figure 1 is a plan view of a sensor for wireless transmission / reception of deformation information using an electroactive polymer according to a first embodiment of the present invention.

[0046] refer to figure 1 The sensor for wireless transmission / reception of deformation information using electroactive polymers in this embodiment includes a first sensor part (10), a second sensor part (20) and an electrode part (30).

[0047] The first sensor part (10) refers to a sensor unit having a fiber shape comprising an electroactive polymer material acting on the principle of ferroelectric behavior. Ferroelectric electroactive polymers have excellent properties for sensors for sensing deformation, such as fast mechanical / electrical ductility response speed (milliseconds to seconds) versus mechanical / chemical behavior and low impedance, high reliability and stability etc. For example, the first sensor part (10) may be polyvinylidene fluoride PVDF. However, various embodi...

no. 2 example

[0084] Figure 9 An example of the structure of a sensor for wireless transmission / reception of deformation information using an electroactive polymer according to an embodiment of the present invention will be described.

[0085] refer to Figure 9 , the fabric sensor (200) (hereinafter referred to as a sensor) for wireless transmission / reception of deformation information using an electroactive polymer according to an embodiment of the present invention is characterized in that Figure 9 An electroactive polymer fiber coil sensor unit ( 210 ) for wireless transmission / reception of deformation information (hereinafter, referred to as a sensor unit) having a shape of a specific fiber yarn woven into a fabric form is shown in .

[0086] As will be explained below, the sensor unit (210) includes a sensor portion comprising an electroactive polymer material and electrodes. The sensor unit (210) is formed in the shape of a fiber yarn. Accordingly, the sensor unit (210) is woven...

no. 3 example

[0110] Figure 13 is a diagram of a structure of a sensor for wireless transmission / reception of deformation information using an electroactive polymer according to a third embodiment of the present invention.

[0111] refer to Figure 13 The sensor for wireless transmission / reception of deformation information using electroactive polymers according to the third embodiment of the present invention may include a first fiber (500) and a second fiber (510) and may further include a third fiber (520).

[0112] The first fiber (500) refers to at least one group of fibers comprising an electroactive polymer material. The electroactive polymer material means all materials having a characteristic of generating a voltage when the electroactive polymer material is deformed by an external force. For example, the first fiber (500) may comprise an electroactive polymer material based on polyvinylidene fluoride that functions through a relaxation oscillator ferroelectric mechanism. Howev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com