Refrigeration method and whole-process cold chain process for very fresh royal jelly

A freezing method and a whole-process cold chain technology, which is applied in food freezing, food processing, and the functions of food ingredients, etc., to achieve the effects of saving cold chain costs, protecting texture, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

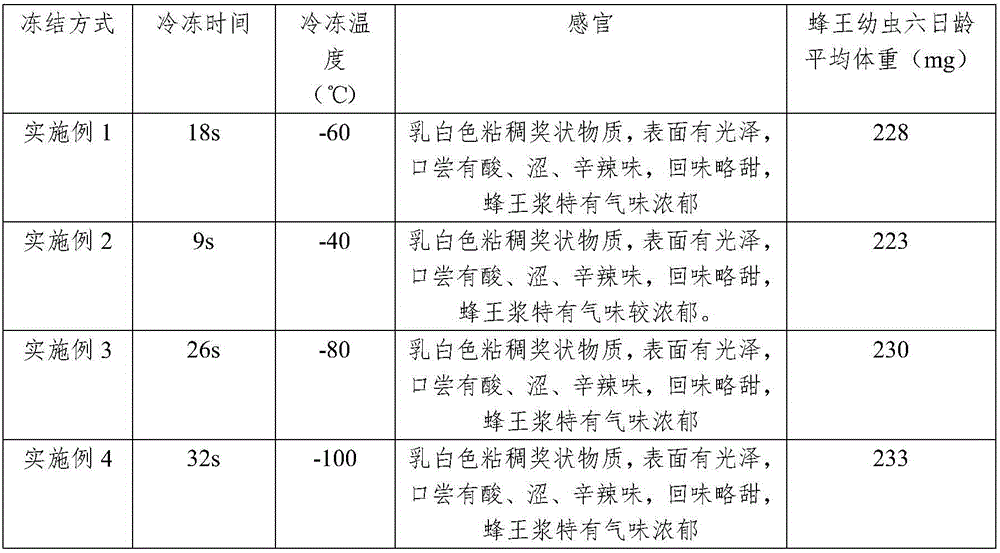

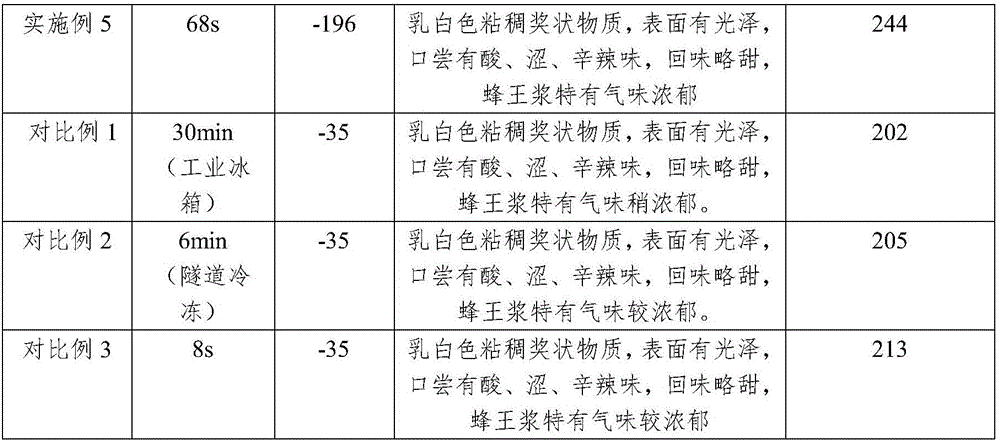

Embodiment 1

[0030] A freezing method of extremely fresh royal jelly, comprising the following operations:

[0031] 1) After taking the royal jelly out of the royal table, place the royal jelly in a liquid nitrogen insulation barrel for 18 seconds, and cool it down to -60°C;

[0032] 2) Place the quick-frozen royal jelly in a freezer at -18°C for 12 months. Embodiment 2-5

Embodiment 2~5

[0033] Compared with Example 1, the difference is that after the royal jelly is taken out from the royal table, it is placed in a liquid nitrogen insulation barrel for 9s, 26s, 32s, and 68s, and the temperature is lowered to -40°C, -80°C, -100°C, respectively. °C, -196 °C.

Embodiment 6

[0035] A whole process cold chain process of extremely fresh royal jelly, comprising the following steps:

[0036] 1) Take the royal jelly out of Wangtai and place it in a liquid nitrogen insulation barrel, take it out after 5 minutes, put it in a -18°C freezer for cryopreservation;

[0037] 2) The cryopreserved royal jelly is transported by a refrigerated vehicle, and the temperature of the refrigerated vehicle is controlled at -10°C. After transporting the cryopreserved royal jelly to the royal jelly processing plant, it is placed in a -18°C freezer within 12 hours; intermediate samples are taken for inspection;

[0038] 3) Take out the royal jelly raw material in the cold storage within one month, thaw naturally at 20°C, stir at 50r / min and filter with 120-mesh gauze to remove impurities, quantitatively distribute, label, and inspect. Finished, then put into -18 ℃ freezer;

[0039] 4) Take out the finished royal jelly product in the cold storage within one month, and trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com